5059 5086 Marine Grade Aluminum Bars

Marine-grade aluminum rods such as 5059 and 5086 combine corrosion resistance, strength and lightweight properties, making them an indispensable material in a variety of marine applications where durability and reliability are important.

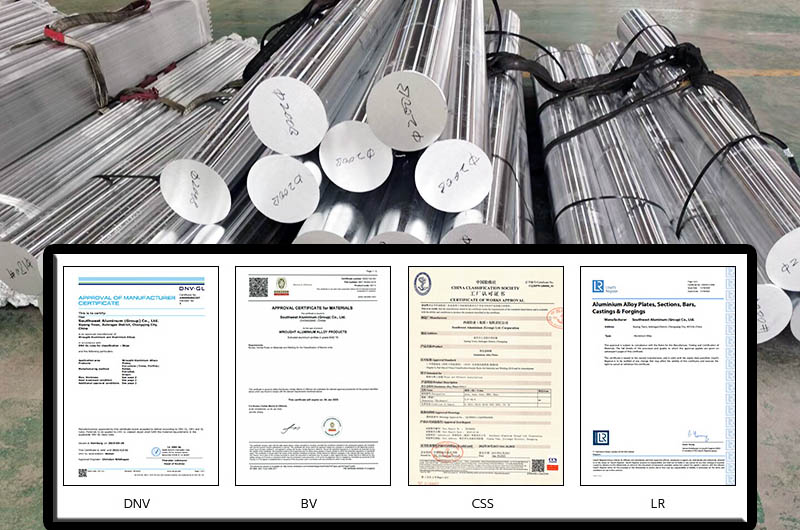

Haomei Aluminum's marine-grade products adopt strict quality and environmental management systems and have passed CCS, DNV, NK, CCS, ABS, BV, LR, and KR certifications.

5059 5086 Marine Grade Aluminum Bars Performance

5059 and 5086 aluminum alloys both belong to the 5xxx series and are characterized by excellent corrosion resistance and weldability. However, each alloy has unique properties that make it suitable for specific applications.

5059 Marine Grade Aluminum Bars

- Enhanced Corrosion Resistance: 5059 aluminum alloy exhibits superior corrosion resistance in marine environments compared to many other aluminum alloys.

- High Strength: 5059 alloy has high tensile strength and good formability, making it ideal for structural applications in marine and offshore environments.

- Weldability: The alloy is easy to weld using conventional methods, allowing for ease of fabrication and assembly in marine construction projects.

5086 Marine Grade Aluminum Bars

- Excellent weldability: Alloy 5086 offers excellent weldability, enabling efficient fabrication of complex structures and components.

- Moderate Strength: While not as strong as some other aluminum alloys, 5086 provides sufficient strength for many marine applications, especially in environments where corrosion resistance is critical.

- Formability: The alloy is easy to form and process, making it suitable for a variety of manufacturing processes.

- Good cutting processability: 5086 aluminum alloy has good cutting processability, is easy to cut, bend and form, and can easily manufacture ship components of various shapes.

Advantages of 5059 and 5086 Marine Grade Aluminum Rods

There are several distinct advantages to using 5059 and 5086 marine grade aluminum rods:

- 1. Corrosion resistance: Both alloys exhibit excellent corrosion resistance in marine environments, extending the service life of structures and equipment exposed to salt water and harsh weather conditions.

- 2. Lightweight: Aluminum is much lighter than steel, making it an attractive choice for applications such as shipbuilding and aerospace where weight reduction is critical.

- 3. Formability and machinability: 5059 and 5086 aluminum alloys can be easily formed, machined and welded, allowing complex structures and components to be manufactured accurately and efficiently.

- 4. Environmental Sustainability: Aluminum is highly recyclable and offers environmental benefits compared to materials such as steel. The use of recycled aluminum in the manufacturing process further reduces the environmental footprint of marine-grade aluminum bars.

5059 5086 Marine Grade Aluminum Bars Type

5059 H112 5086 O H112 Marine Grade Aluminum Round Rod: This refers to the H112 condition round rod made of 5059 aluminum alloy, suitable for marine applications that require strength and corrosion resistance.

5059 5086 Marine Grade Aluminum Square Bars: Made from aluminum alloy 5086, these square bars are available in both annealed (O) and strain hardened (H112) tempered conditions. These rods may be suitable for marine structural applications.

5059 H112 5086 O H112 Marine Grade Aluminum Hexagon Rod: This represents a hexagonal rod made from a combination of aluminum alloys 5059 and 5086, with different tempering conditions (H112 and O). This product balances the properties of both alloys to meet specific marine engineering needs.

Mechanical properties of 5059 5086 marine grade aluminum bars

| Alloy | 5059 | 5086 | |||||

| Temper | H112 | O | H112 | ||||

| Thickness mm | ≤12.50 | >12.5-50.00 | ≤12.50 | >12.50-200.00 | ≤12.50 | >12.50-250.0 | |

| Tensile Strength RmMPa | 330 | 330 | 240-315 | 240-315 | 240 | 240 | |

| Specified non-proportional tensile strength Rp0.2 Mpa | 200 | 200 | 95 | 95 | 95 | 95 | |

| Elongation% | A50 mm | - | 10 | - | 18 | - | 12 |

| A | 10 | - | 15 | - | 12 | - | |

Chemical composition of 5059 5086 marine grade aluminum bars

| Param | 5059 | 5086 |

| Al | Rest | Rest |

| Mg | 4.8-5.5 | 3.5-4.5 |

| Mn | 0.5-1.0 | 0.2-0.7 |

| Cr | 0.05-0.25 | 0.05-0.25 |

| Zn | 0.25-0.6 | 0.25 |

| Cu | 0.1 | 0.1 |

| Ti | 0.15-0.35 | 0.15-0.35 |

| Si | 0.25 | 0.4 |

| Fe | 0.4 | 0.5 |

| Sn | 0.2 |

5059 5086 Marine Grade Aluminum Bars Applications

The versatility and durability of 5059 and 5086 marine grade aluminum bars make them indispensable in a variety of industries.

- 1. Shipbuilding: From hull structures to superstructure components, 5059 and 5086 aluminum rods play a vital role in the modern shipbuilding industry. They combine strength and corrosion resistance to ensure the longevity and reliability of your vessel.

- 2. Offshore structures: Oil rigs, offshore platforms and other marine structures face harsh environmental conditions, including salt water exposure and corrosive elements. 5059 and 5086 aluminum rods provide the structural integrity needed to meet these challenges while maintaining operational efficiency.

- 3. Marine equipment: In addition to structural applications, marine grade aluminum rods can also be used to manufacture marine equipment such as ship frames, masts and railings. Their lightweight nature and corrosion resistance make them ideal for components that require durability without adding excessive weight.

- 4. Construction Applications: The aesthetics, durability, and corrosion resistance of 5059 and 5086 aluminum rods also make them a popular choice for construction applications, including waterfront developments, bridges, and coastal infrastructure.

Overall, the use of 5059 and 5086 marine-grade aluminum rods highlights the importance of materials engineering in meeting the unique challenges posed by the marine environment. From shipbuilding to offshore structures and construction applications, these alloys offer the perfect combination of strength, durability and corrosion resistance.

Recommended for you

-

5086 aluminum alloy round bars achieve high strength through cold mechanical processing, offering excellent seawater corrosion resistance and weldability. They are specifically designed for shipbuilding, marine engineering, and transportation equipment.

-

Professional production of 5086 aluminum flat bars, complete product specifications, direct sale from the manufacturer, favorable prices, strict quality control to ensure compliance with ASTM, EN, and other international standards.

-

As a professional aluminum alloy material manufacturer, we offer 5086 H111 aluminum alloy round bars, specially designed for harsh environments, suitable for shipbuilding, marine engineering, and industrial structural fields.

Other content readers are interested in

-

5086 marine grade aluminium checkered tread plate sheet

5086 marine grade aluminum checkered tread plate sheet has higher strength and corrosion resistance than 5052 and 5083 plates, making it ideal for many marine and marine applications.

-

5059 Marine Grade Aluminum Plate Sheet

5059 marine-grade aluminum offers many benefits to the shipbuilding industry, including reduced weight, increased load capacity, improved stability and speed, corrosion resistance and versatility.

-

5086 Marine Grade Aluminum Plate Sheet

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

5059 H116 aluminum alloy is suitable for applications that need to withstand high stresses, long-term fatigue and highly corrosive environments.

-

5059 H111 is a condition of 5059 aluminum alloy, where "H111" indicates that it has undergone certain processing techniques to achieve a strength level lower than the H11 condition, typically through strain hardening and cold working.

-

5059-H321 aluminum alloy is the version of 5059 aluminum alloy in the H321 condition, which has undergone strain hardening and stabilization treatment.

-

As a direct manufacturer of 5086 Aluminum Sheet, we offer marine-grade aluminum plates that meet ASTM B209/EN 485 standards, featuring excellent seawater corrosion resistance and weldability.

-

As a professional aluminum plate manufacturer, we offer high-performance 5086 H116 aluminum alloy plates in a variety of specifications to meet the lightweight and industrial requirements of hulls.

-

As a leading manufacturer of aluminum alloys, we specialize in supplying 5086 H32 aluminum plate, ideal for harsh marine, industrial, and structural applications.

-

Our company specializes in the production of 5086 H111 medium-thick aluminum plates, with a finely polished surface and strong resistance to seawater corrosion. We offer customized cutting and welding services, and provide international certifications such as BV/DNV/ABS, with quick response to custom needs.

-

As a professional manufacturer of 5086 aluminum tubes, we offer seamless cold drawn aluminum tubes that comply with ASTM B210/B221 standards, with material strengthened by magnesium alloys, combining high strength and excellent seawater corrosion resistance.

-

5086 Aluminum Round Tubes and Pipes

As a professional aluminum alloy tube manufacturer, we offer 5086 aluminum alloy seamless round tubes, produced using high-precision cold drawing processes, conforming to international standards such as ASTM B210.

-

As a professional aluminum material manufacturer, we offer high-quality 5086 aluminum alloy square tubes, specifically designed for ships, marine engineering, and high-corrosion environments.

-

5086 Aluminum Drawn Seamless Pipe

As a leading manufacturer of precision aluminum products, we specialize in producing 5086 Aluminum Drawn Seamless Pipes designed for harsh environments.

-

As a professional 5086 H32 pipe manufacturer, we provide high-performance, seawater corrosion-resistant customized pipe products, combining excellent strength and lightweight properties. Non-standard size processing is supported, and products are tested according to ISO certification and ASTM/EN standards.

-

As a leading supplier of 5086 aluminum alloy angles, we offer a full range of sizes in 5086-H111 structural angles, suitable for marine ladders, pressure vessels, and transportation equipment.

-

As a professional aluminum material manufacturer, we provide 5086 H111 aluminum alloy angles, combining high strength and excellent corrosion resistance, especially suitable for the marine, offshore engineering, and industrial structural fields.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5454 aluminum alloy not only possesses excellent corrosion resistance, but its unique high-temperature stress resistance makes it irreplaceable in welded structures for ship fuel tanks and high-temperature environments.

-

6061 marine aluminum has good corrosion resistance, high strength, good machinability and welding performance, and is suitable for marine structural parts.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

More content of interest to readers

What is the difference between 5086 and 6061 aluminum? 5086 H32 vs H116 What is 5086 grade aluminum? 5086 Aluminum vs 5052 5059-H116 Aluminum vs. 5059-H321 Aluminum 5059 Aluminum vs. 5083 Aluminum 5059-H111 Aluminum vs. 5059-H116 Aluminum 5086 Aluminum vs. 5456 Aluminum 5086 and 5083 Aluminum Materials in Shipbuilding 5083 vs. 5059: Aluminum Alloy Selection in Shipbuilding

You might be interested in: Marine Aluminum 5059 Marine Aluminum 5086