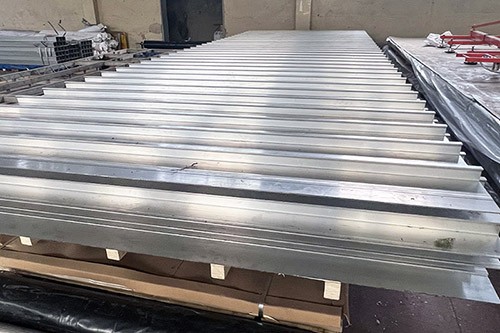

Marine grade ribbed stiffener aluminum plate sheet

Marine-grade ribbed aluminum panels are typically made from high-quality aluminum alloys, such as 5000 series or 6000 series alloys. These alloys were chosen for their excellent corrosion resistance, strength and weldability.

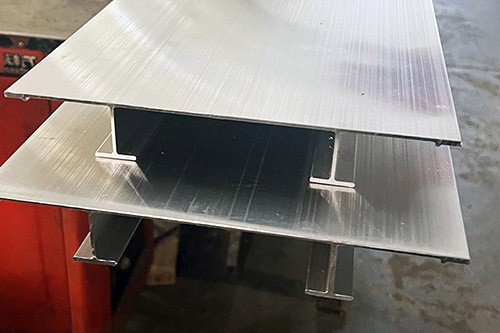

A ribbed aluminum plate is an aluminum sheet with a ribbed surface structure, typically used to enhance structural strength or improve heat dissipation performance.

This type of aluminum plate is generally used in structural applications that require increased rigidity, bending resistance, or lightweight characteristics, and is widely used in industries such as aerospace, transportation, architectural decoration, and mechanical manufacturing.

Marine grade ribbed aluminum plate sheet Ribbed Design

The ribbed design refers to the pattern of raised ridges or ribs on the surface of the aluminum sheet. These ribs enhance the strength and rigidity of the sheet, making it suitable for use in applications where structural integrity is important

- Ribbed Structure: The surface of the plate features ribbed reinforcements, which not only provide additional structural strength but also effectively disperse loads, enhancing the plate's resistance to bending and twisting.

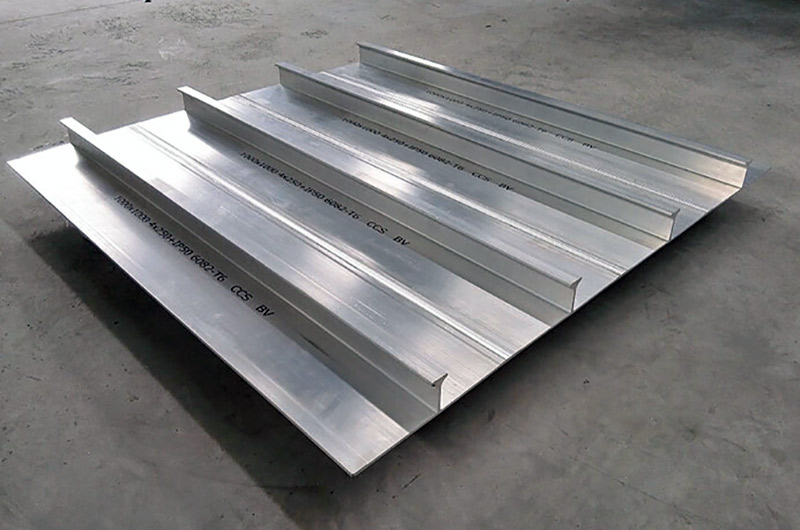

- Multi-rib Design: The design of the ribs can be parallel, staggered, or in other forms to meet different mechanical requirements.

Marine grade ribbed aluminum plate sheet characteristics

Marine grade ribbed aluminum plate sheet has an excellent strength to weight ratio, making it ideal for marine applications where weight reduction is required without compromising structural integrity. The ribbed design adds extra strength and stiffness to the board, allowing it to withstand heavy loads and harsh marine conditions.

The surface of the ribbed aluminum plate features regularly spaced protruding ribs, a structural design primarily used to enhance the rigidity, bending resistance, and heat dissipation capacity of the aluminum plate. It typically possesses the following characteristics:

- Enhanced Strength and Rigidity: The ribbed structure effectively increases the strength and rigidity of the aluminum plate while maintaining a relatively lightweight. This both reduces overall weight and improves structural stability. High-strength aluminum alloys such as 6082-T6, 5083-H116, etc., are commonly used.

- Bending Resistance: The evenly distributed ribs provide the ribbed aluminum plate with better ability to disperse and withstand external forces, offering superior bending resistance.

- Corrosion Resistance: Ribbed aluminum plates are usually made from aluminum alloys such as 5083, 5754, 6061, 7075, etc., which exhibit excellent corrosion resistance, especially in marine environments. Marine-grade aluminum alloys (like 5083 and 5754) significantly improve resistance to salt spray and seawater corrosion by adding elements like magnesium and manganese, making them suitable for long-term use in marine environments.

- Heat Dissipation: The protruding ribs help to increase the surface area of the aluminum plate, thereby enhancing heat dissipation efficiency. This feature is particularly important in high-temperature environments or applications that require high heat dissipation.

- Lightweight: Despite enhanced strength and rigidity, ribbed aluminum plates still maintain their lightweight advantage, making them suitable for applications that require reduced weight.

- Weight Reduction: With a density only one-third that of steel, ribbed aluminum plates reduce transportation and installation costs, making them especially suitable for ships and offshore platforms.

- Machinability: Ribbed aluminum plates can be processed by cutting, bending, welding (such as friction stir welding), etc., to meet the requirements of complex structural designs.

Ribbed Aluminum Plate Specifications

The specifications of ribbed aluminum plates can be customized based on different application requirements. Common specifications include:

| Specification Item | Description |

| Thickness | Typically ranges from 1mm to 10mm, and can be thicker or thinner as required. |

| Width and Length | Common widths range from 500mm to 2000mm, with standard lengths ranging from 2000mm to 6000mm, and custom lengths are available based on demand. |

| Rib Height and Spacing | Rib height generally ranges from 10mm to 100mm, with spacing from 50mm to 200mm, optimized based on mechanical needs. |

| Alloy Type | Common alloys include 5083 (corrosion-resistant), 6082 (high-strength), 7075 (super hard), etc., suitable for different working conditions. |

| Surface Treatment | Common surface treatments include anodizing, electrophoresis coating, and spraying to enhance corrosion resistance and aesthetics. |

Haomei Marine Grade Ribbed Stiffener Aluminum Plate Sheet

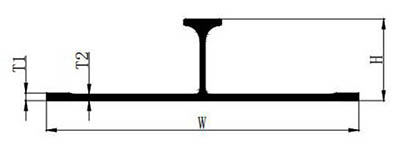

-

Designed with only one rib, primarily used to bear light mechanical stress and increase structural rigidity.

Suitable for non-high-strength requirements in hull components.

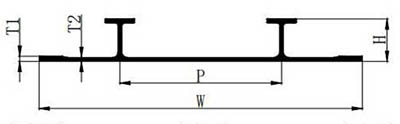

-

Features two ribs, providing better strength and rigidity, suitable for medium mechanical stress.

Commonly used in the sides and bottom of the hull, effectively resisting waves and impacts.

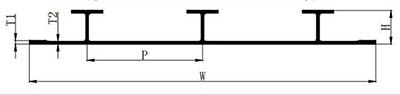

-

Equipped with multiple ribs, offering higher strength and torsional performance, suitable for bearing significant mechanical loads.

Often used in the primary load-bearing structures of ships, such as hull frames and decks.

Marine grade ribbed aluminum plate sheet advantages

The ribbed aluminum plate structure brings significant advantages in terms of geometric accuracy, residual stress, and number of welds. It is especially suitable for the field of shipbuilding and has brought many economic benefits and environmental friendliness to the shipbuilding industry. This structural design not only makes the overall stability and local stability surpass the traditional template, but also reduces the welding workload and environmental pollution, while extending the ship repair service cycle and increasing the total service life.

- The ribbed aluminum plate structure has high geometric precision. Since its structural section and positioning are determined by the extrusion die, the error caused by traditional manual welding is reduced, making the ribbed plane close to the geometric plane, which enhances the stability of the structure.

- The residual stress of this structure is small, usually less than 20MPa, and its impact on the load-bearing capacity is negligible. This makes the ribbed aluminum plate more reliable in practical applications, and its structural strength and stability are better than traditional plates.

- The ribbed aluminum plate design reduces the number of welded joints connecting ordinary longitudinal profiles, thereby reducing the number of welds and welding deformations, reducing the welding workload and the complexity of subsequent correction work.

- This structural design also brings significant economic benefits. The reduction of residual stress allows ribbed aluminum plates to be considered an ideal material, thereby improving its manufacturability, extending the ship repair service cycle, and increasing the total service life. At the same time, the reduced welding workload also reduces environmental pollution, reflecting the positive contribution of the manufacturing industry to sustainable development.

Marine grade ribbed aluminum plate sheet composition

Marine-grade ribbed aluminum panels are typically made from high-quality aluminum alloys, such as 5000 series or 6000 series alloys. These alloys were chosen for their excellent corrosion resistance, strength and weldability.

Aluminum Alloys: High-strength aluminum alloys, such as 6061 or 5083, are commonly used to enhance corrosion resistance and mechanical strength.

Corrosion Resistance: Treated with anodization or other surface treatments to improve their corrosion resistance in marine environments.

| Composition | 6061 Aluminum Alloy (%) | 5083 Aluminum Alloy (%) |

| Aluminum (Al) | Balance | Balance |

| Silicon (Si) | 0.4 - 0.8 | 0.40 - 0.70 |

| Iron (Fe) | 0.7 | 0.40 |

| Copper (Cu) | 0.15 - 0.40 | 0.10 |

| Manganese (Mn) | 0.15 - 0.40 | 0.40 - 1.00 |

| Magnesium (Mg) | 0.8 - 1.2 | 4.0 - 4.9 |

| Chromium (Cr) | 0.04 - 0.35 | 0.05 - 0.25 |

| Zinc (Zn) | 0.25 | 0.25 |

| Titanium (Ti) | 0.15 | 0.15 |

| Other Elements | Total of each element must not exceed 0.15 | Total of each element must not exceed 0.10 |

Marine grade ribbed aluminum plate sheet applications

Ribbed Aluminum Plate in Marine Applications

Marine Industry: In marine applications, ribbed aluminum plates are widely used in shipbuilding, offshore platforms, and marine facilities due to their corrosion resistance and structural stability.

| Application Field | Description |

| Shipbuilding | Ribbed aluminum plates are used in hulls, bottoms, decks, and other parts of ships to enhance structural strength and improve corrosion resistance. Given the strong corrosive nature of seawater, the corrosion resistance of ribbed aluminum plates is a key advantage, making them especially suitable for marine equipment and ship structures. |

| Offshore Platforms | Ribbed aluminum plates are used in the structural components of offshore drilling platforms and marine production platforms. Their strength and corrosion resistance ensure the stability and safety of the platforms in harsh marine environments. |

| Marine Facilities | For marine facilities such as offshore wind power platforms and marine monitoring equipment, ribbed aluminum plates improve durability and stability while reducing maintenance costs. |

| Marine Engineering | In marine engineering applications, such as submersibles, underwater pipelines, and marine exploration equipment, ribbed aluminum plates are ideal due to their lightweight, high strength, and excellent corrosion resistance. |

| Protective Structures | In coastal protection and port facilities, ribbed aluminum plates are highly resistant to seawater corrosion, effectively withstanding harsh environmental conditions and extending the lifespan of the structures. |

Other Applications of Ribbed Aluminum Plate

Ribbed aluminum plates, due to their excellent physical properties, are widely used in various industries. Some of the main applications include:

- Aerospace: Ribbed aluminum plates provide the necessary strength and bending resistance in parts of aircraft, especially in the fuselage and wings, which require both high rigidity and lightweight properties.

- Automotive Manufacturing: Ribbed aluminum plates are used in automotive chassis, vehicle frames, engine hoods, and other components to improve structural strength and reduce vehicle weight.

- Architecture: Ribbed aluminum plates are used in curtain walls, ceilings, and wall decorations, particularly in applications that require both decorative appeal and the ability to withstand certain loads.

- Heat Dissipation Equipment: Due to their excellent heat dissipation properties, ribbed aluminum plates are widely used in radiators, heat exchangers, and other equipment.

Ribbed Aluminum Plate Production Process

The production process of ribbed aluminum plates typically involves the following key steps:

- Selection of Aluminum Alloy Materials: Choose the appropriate aluminum alloy based on application requirements, commonly used alloys include 5083, 6061, 7075, etc.

- Extrusion Process: Use extrusion equipment to force the aluminum alloy material through a mold to form the plate. During the extrusion process, different mold designs can be selected to ensure the plate surface has a ribbed structure.

- Heat Treatment: To enhance the strength and corrosion resistance of the aluminum plate, ribbed aluminum plates are typically subjected to heat treatment (such as T6 temper treatment).

- Surface Treatment: The surface of the aluminum plate may undergo anodizing, spraying, or coating to enhance corrosion resistance and wear resistance.

- Cutting and Processing: Based on customer requirements, ribbed aluminum plates can be cut into different specifications and sizes and subjected to other subsequent processing, such as drilling and bending.

The application of ribbed aluminum plates in the marine industry is primarily due to their excellent strength, corrosion resistance, and lightweight characteristics. In marine environments, ships, offshore platforms, marine facilities, and other structures must withstand extreme working conditions. Ribbed aluminum plates, with their unique structural design and material properties, provide effective support and protection for these devices.

Haomei marine grade ribbed stiffener aluminum plate sheet stock sizes

| Single stiffener panel | ||||

| T1 | T2 | W | H | L |

| (mm) | (mm) | (mm) | (mm) | (mm) |

| 2.8 | 1.8 | 200 | 60 | 12500 |

| 4 | 3 | 250 | 43 | 12500 |

| 300 | 43 | |||

| 400 | 43 | |||

| 5 | 4 | 250 | 64 | 12500 |

| 300 | 54 | |||

| 6 | 5 | 250 | 55 | 12500 |

| 300 | 55 | |||

| 7 | 6 | 250 | 56 | 12500 |

| 300 | 66 | |||

| 8 | 7 | 250 | 57 | 12500 |

| 300 | 67 | |||

| 9 | 8 | 250 | 68 | 12500 |

| 300 | 68 | |||

| 9.6 | 9 | 250 | 59 | 12500 |

| Double-stiffened panel | |||||

| T1 | T2 | W | H | P | L |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) |

| 3 | 1.9 | 212 | 32.5 | 106 | 12500 |

| 2 | 270 | 37 | 135 | ||

| 3.5 | 2.5 | 270 | 37.5 | 135 | 12500 |

| 4 | 3 | 252 | 33 | 126 | 12500 |

| 320 | 38 | 160 | |||

| Multi stiffened panel | |||||

| T1 | T2 | W | H | P | L |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) |

| 3.5 | 2.5 | 345 | 37.5 | 115 | 12500 |

Marine-grade ribbed aluminum is a material specifically engineered to withstand the harsh conditions of the marine environment while providing exceptional strength, durability and corrosion resistance. Its ribbed design enhances structural integrity, making it ideal for a variety of marine applications.

Content you may be interested in

-

Marine grade multi ribbed stiffener aluminum plate sheet

Marine grade multi ribbed stiffener aluminum plate is a type of aluminum alloy material specifically designed for shipbuilding. Its main feature is the addition of multiple rib stiffeners on the surface of the aluminum plate to enhance its strength and stiffness.

-

Marine grade double ribbed stiffener aluminum plate sheet

Marine double-rib aluminum plates provide stronger structural support than single-rib aluminum plates and are suitable for high-load applications.

-

Marine grade single ribbed stiffener aluminum plate sheet

Marine grade single ribbed stiffener aluminum plate is a specially designed aluminum alloy material for shipbuilding, featuring a single rib structure to enhance its strength and rigidity.