Marine Aluminum Profiles

Marine aluminum profiles play a critical role in marine engineering, shipbuilding, and offshore facility construction. They are widely used in various marine environments due to their excellent corrosion resistance, lightweight, high strength, and good processing performance.

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

Marine aluminum profiles play a critical role in marine engineering, shipbuilding, and offshore facility construction. They are widely used in various marine environments due to their excellent corrosion resistance, lightweight, high strength, and good processing performance.

The lightweight nature of marine aluminum profiles can effectively reduce the overall weight of the vessel, improving fuel efficiency.

Haomei Aluminum - Premium Marine-Grade Aluminum Supplier

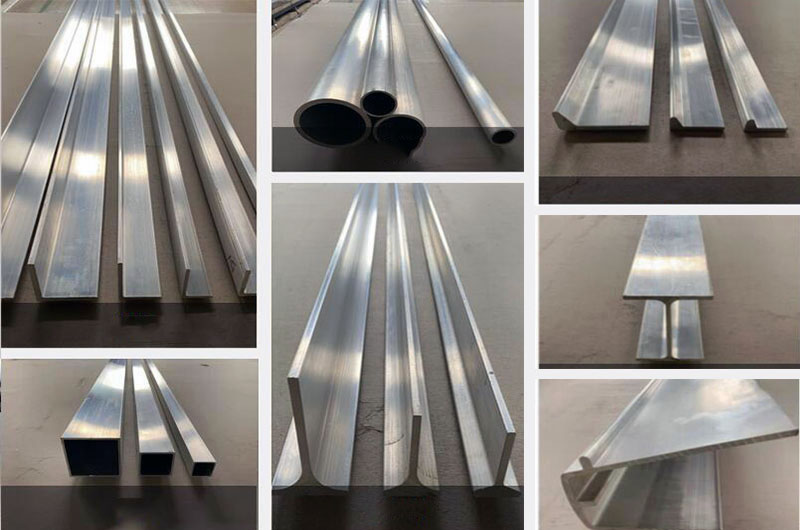

- Products: Marine Aluminum Plate, Marine Aluminum Tube, Marine Grade Flat Aluminum, Marine Grade Aluminum Plate, Marine Grade Angular Aluminum, Marine Grade T-Type Aluminum, Marine Grade I-Type Aluminum, Marine Grade Square Tube, Marine Grade Aluminum Trough, and other marine aluminum products.

- Comprehensive Marine Aluminum Certifications: CCS, DNV, NK, CCS, ABS, BV, LR, KR, etc.

Popular Marine Aluminum Profiles

Marine aluminum profiles are typically supplied in various shapes and sizes to meet different design needs. Common shapes include:

- Profiles: Such as L-shaped, T-shaped, H-shaped, U-shaped, etc., suitable for hull frames and support structures.

- Tubes: Round, square, or rectangular tubes, used for masts, railings, and other support structures.

- Plates: Used for hull covering, decks, and other large surface structural components.

-

Marine Aluminum Tube

A cylindrical hollow profile made of marine aluminum, commonly used in piping, railings, and frames in shipbuilding and marine structures due to its corrosion resistance and high strength.

-

Marine Grade Flat Aluminum

A flat, rectangular marine aluminum sheet or strip used for structural components, decks, and other flat surfaces on ships.

-

Marine Grade Aluminum Bulb Flat extrusions

The advantages of Aluminum Bulb Flat Extrusions over other types of extrusions are significant. Compared to traditional extrusions such as angles or flats, bulb flats offer better performance in load distribution and structural reinforcement.

-

Marine Grade Angular Aluminum

L-shaped or angled aluminum profiles used for reinforcing edges, frames, and supports in marine structures. They are valued for their ability to provide structural support and resist corrosion.

-

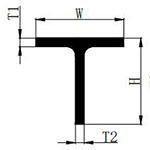

Marine Grade T-Type Aluminum

A T-shaped profile made of marine aluminum, used to connect or reinforce parts at right angles, commonly used in building frames and brackets on ships.

-

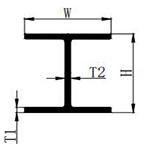

Marine Grade I-Type Aluminum

An I-beam or H-shaped profile used in marine applications that require high strength, commonly used in constructing beams, joists, and structural supports.

-

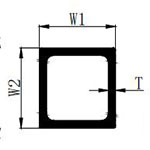

Marine Grade Aluminum Square Tube

A hollow square aluminum profile used in frameworks, railings, and other structural applications where both strength and corrosion resistance are critical.

-

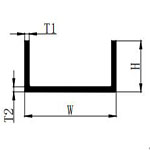

Marine Grade Aluminum Trough

A U-shaped or channel profile used in drainage systems, cable management, and structural components in marine environments. It helps guide or support materials while resisting corrosion.

What Types of Aluminum Are Used for Marine Aluminum Profiles?

Marine aluminum profiles generally use 6082, 6061, 6063, and 5083 aluminum alloys.

- 5083: 5083 is ideal for applications requiring excellent corrosion resistance in harsh environments.

- 6061: 6061 offers excellent corrosion resistance and is easier to machine and weld compared to 5052 aluminum alloy.

- 6063: 6063 aluminum alloy is primarily used for architectural and decorative purposes rather than structural support. It has excellent corrosion resistance, tensile properties, and finishing characteristics.

- 6082: 6082 has excellent corrosion resistance and weldability, high strength, and good machinability.

5083 Marine Aluminum Profile

- Main Characteristics: High corrosion resistance, particularly suitable for seawater environments, with good strength and weldability.

- Common Tempers: H111, H116, H321.

- Main Applications: Hulls, shells, decks, and other structural components.

6061 Marine Aluminum Profile

- Main Characteristics: High strength, good corrosion resistance, and excellent mechanical properties, suitable for components that need to withstand high loads.

- Common Tempers: T6.

- Main Applications: Ship frames, masts, railings, and other high-strength structural components.

6082 Marine Aluminum Profile

- Main Characteristics: Excellent corrosion resistance and weldability, high strength, and good machinability.

- Common Tempers: T6.

- Main Applications: Ship structural components, marine railings, and other high-strength parts.

6063 Marine Aluminum Profile

- Main Characteristics: Good corrosion resistance and weldability, high strength, and excellent surface treatment performance, often used to manufacture finely processed components.

- Common Tempers: T5, T6.

- Main Applications: Ship frames, railings, hatches, and other decorative or light-load structural components.

Specifications for Marine Aluminum Profiles

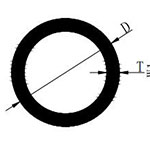

Marine Aluminum Tube Typical Specifications

| Diameter (D) mm | 22 | 35 | 45 | 50 | 60 | 70 | 80 | 108 | 120 | 130 |

| Thickness (T) mm | 3 | 5 | 4 | 3 | 6 | 5 | 5 | 8 | 5 | 10 |

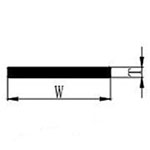

Marine Grade Flat Aluminum Typical Specifications

| Width (D) mm | 40 | 50 | 60 | 80 | 100 | 120 | 150 | 180 | 250 |

| Thickness (T) mm | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 8 | 10 |

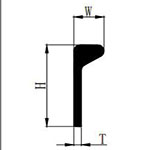

Marine Grade Aluminum Bblate Typical Specifications

| Height (H) mm | 40 | 50 | 60 | 80 | 90 | 100 | 120 | 140 | 160 |

| Width (W) mm | 14 | 16 | 18 | 18 | 21 | 18.75 | 21 | 18.75 | 21 |

| Thickness (T) mm | 3.5 | 3.5 | 4 | 4.2 | 6 | 4 | 7 | 7 | 7 |

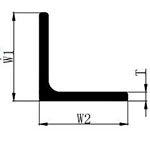

Marine Grade Angular Aluminum Typical Specifications

| Width 1 (W1) mm | 25 | 30 | 40 | 50 | 60 | 70 | 100 | 185 |

| Width 2 (W2) mm | 25 | 30 | 40 | 50 | 50 | 50 | 100 | 50 |

| Thickness (T) mm | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 10 |

Marine Grade T-Type Aluminum Typical Specifications

| Height (H) mm | 40 | 50 | 60 | 65 | 70 | 80 |

| Width (W) mm | 40 | 50 | 60 | 70 | 80 | 80 |

| Thickness 1 (T1) mm | 4 | 4 | 5 | 6 | 6 | 7.5 |

| Thickness 2 (T2) mm | 4 | 4 | 4 | 6 | 6 | 7.5 |

Marine Grade I-Type Aluminum Typical Specifications

| Height (H) mm | 125 | 80 | 100 | 76.2 | 50 | 120 | 140 | 270 | 280 |

| Width (W) mm | 125 | 80 | 100 | 76.2 | 50 | 120 | 140 | 150 | 100 |

| Thickness 1 (T1) mm | 6 | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 |

| Thickness 2 (T2) mm | 6 | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 |

Marine Grade Aluminum Square Tube Typical Specifications

| Width 1 (W1) mm | 25 | 30 | 40 | 50 | 60 | 70 | 75 | 100 | 100 |

| Width 2 (W2) mm | 25 | 30 | 40 | 50 | 50 | 70 | 75 | 100 | 100 |

| Thickness (T) mm | 2.5 | 3 | 4 | 4 | 5 | 4 | 6 | 4 | 6 |

Marine Grade Aluminum Trough Typical Specifications

| Width (W) mm | 25 | 40 | 50 | 100 | 150 | 152.4 | 203.2 |

| Height (H) mm | 25 | 50 | 50 | 50 | 50 | 76.2 | 102.3 |

| Thickness 1 (T1) mm | 3 | 5 | 5 | 5 | 6 | 6 | 9.5 |

| Thickness 2 (T2) mm | 3 | 5 | 5 | 5 | 6 | 6 | 9.5 |

Chemical Composition of Marine Aluminum Profiles

| Alloy Grade | Silicon (Si) | Iron (Fe) | Copper (Cu) | Manganese (Mn) | Magnesium (Mg) | Chromium (Cr) | Zinc (Zn) | Titanium (Ti) | Other Elements | Aluminum (Al) |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.15 max | Remainder |

| 6061 | 0.4-0.8 | 0.7 max | 0.15-0.4 | 0.15 max | 0.8-1.2 | 0.04-0.35 | 0.25 max | 0.15 max | 0.15 max | Remainder |

| 6063 | 0.2-0.6 | 0.35 max | 0.1 max | 0.1 max | 0.45-0.9 | 0.1 max | 0.1 max | 0.1 max | 0.15 max | Remainder |

| 6082 | 0.7-1.3 | 0.5 max | 0.1 max | 0.4-1.0 | 0.6-1.2 | 0.25 max | 0.2 max | 0.1 max | 0.15 max | Remainder |

Marine Aluminum Profiles Mechanical Properties

6082 Marine Aluminum Profiles Mechanical Properties

| Temper | T6 | T651 |

| Density | 2.70 g/cm³ | 2.68g/cm³ |

| Tensile Strength | 250-310MPa | >=295MPa |

| Elongation | 10% | 8% |

| Thermal Conductivity | 170 W/m-K | 220.0 W/m-K |

6063 Marine Aluminum Profiles Mechanical Properties

| Tensile Strength (psi) | Yield Strength (psi) | Elongation (% in 2″) | Brinell Hardness |

| 27, 000 | 21, 000 | 12 | 60 |

6061 Marine Aluminum Profiles Mechanical Properties

| 6061-T6 | 6061-T651 | |

| Shear Strength | 210MPa | 210MPa |

| Tensile Strength | 270-310MPa | 270-320 MPa |

| Elastic Modulus | 69GPa | 69GPa |

| Brinell Hardness | 93HB | 93HB |

| Elongation | 10% | 11% |

5083 Marine Aluminum Profiles Mechanical Properties

| Tensile strength (σb) | 110-136MPa |

| Yield strengthσ0.2 (MPa) | ≥110 |

| Elongationδ10 (%) | ≥20 |

| Elastic modulus (E) | 69.3~70.7Gpa |

| Annealing temperature | 415℃ |

Advantages of Marine Aluminum Profiles

- Lightweight: Aluminum is much lighter than traditional steel, which helps reduce the overall weight of the vessel, increasing cargo capacity or fuel efficiency.

- Corrosion Resistance: Aluminum alloys have excellent resistance to corrosion in seawater, extending the lifespan of the vessel.

- Workability: Aluminum is easy to cut, weld, and form, making it convenient for shipbuilding and repairs.

- Eco-Friendliness: Aluminum is recyclable, aligning with the environmental requirements of modern shipbuilding.

Marine Aluminum Profiles Applications

Aluminum boat trims are primarily used for the external decoration and protection of the boat hull. These aluminum alloy profiles provide an aesthetic and corrosion-resistant decorative effect, typically applied around the edges of the hull, hatches, and deck areas. Due to the lightweight and durable characteristics of aluminum alloys, they effectively prevent seawater corrosion, ensuring the boat's appearance and performance over long-term use.

Aluminum Boat Handrails

Aluminum boat handrails provide safety and stability, helping crew members and passengers maintain balance and walk on board. Boat handrails are typically installed in areas such as the cabin, deck, or stairs. The aluminum alloy material gives the handrails high strength and corrosion resistance, while being lightweight, easy to install, and maintain.

Boat Trailers and Ladders

Boat trailers are used for transporting and storing boats, and they are usually made of aluminum alloy profiles to ensure structural strength and durability. The corrosion resistance of aluminum guarantees the trailer's longevity in humid environments. Boat ladders are used to help people board and disembark from the boat. Aluminum boat ladders are not only lightweight but also corrosion-resistant, ensuring long-term use in seawater environments.

Boat Gratings and Deck Houses

Boat gratings are typically used for drainage and ventilation on decks and other areas. Aluminum alloy gratings have excellent corrosion resistance and can withstand the vibrations and wear of the boat during navigation. Deck houses, as additional structures on the boat, are typically built using aluminum alloy profiles, offering waterproof, corrosion-resistant, and wind-resistant properties, providing comfortable space and protection.

Boat Windscreen Frames

Aluminum boat windscreen frames are used to support the boat’s windows and doors, protecting crew members from wind and seawater. The aluminum alloy frames not only provide strength and rigidity but also perform excellently in marine environments due to their corrosion resistance. Their lightweight design helps reduce the boat’s overall weight and improve its performance.

| Application | Recommended Alloys | Reasons |

| Aluminum Boat Trims | 5005, 5083, 6061 | 5005 Alloy: Good corrosion resistance and machinability, suitable for decorative applications. |

| 5083 Alloy: Excellent corrosion resistance, especially suitable for use in seawater environments. | ||

| 6061 Alloy: Good strength, weldability, and corrosion resistance, suitable for structural boat trim. | ||

| Aluminum Boat Handrails | 5083, 5086, 6061 | 5083 Alloy: Excellent corrosion resistance, ideal for boat handrails in marine environments. |

| 5086 Alloy: Strong corrosion resistance and high strength, suitable for handrails exposed to seawater over long periods. | ||

| 6061 Alloy: Good mechanical properties and machinability, suitable for high-strength and aesthetically pleasing boat handrails. | ||

| Boat Trailers and Ladders | 6061, 7075, 5083 | 6061 Alloy: Good strength, corrosion resistance, and machinability, suitable for structural needs of boat trailers and ladders. |

| 7075 Alloy: Extremely high strength, suitable for load-bearing parts of the trailer structure. | ||

| 5083 Alloy: Strong corrosion resistance, ideal for ladder components exposed to seawater. | ||

| Boat Gratings and Deck Houses | 5086, 6061, 5052 | 5086 Alloy: Excellent corrosion resistance in marine environments, suitable for gratings and deck structures. |

| 6061 Alloy: Suitable for more structural deck houses and platforms, able to bear large weights and maintain stability. | ||

| 5052 Alloy: Good formability and corrosion resistance, suitable for lighter grating or deck structures. | ||

| Boat Windscreen Frames | 6061, 5086, 5052 | 6061 Alloy: High strength, weldability, and corrosion resistance, suitable for windscreen frames. |

| 5086 Alloy: Excellent corrosion resistance, suitable for windscreen frames exposed to seawater for extended periods. | ||

| 5052 Alloy: Corrosion resistance and machinability, ideal for complex-shaped windscreen frames. |

Content you may be interested in

-

Marine Grade Aluminum Bulb Flat extrusions

The advantages of Aluminum Bulb Flat Extrusions over other types of extrusions are significant. Compared to traditional extrusions such as angles or flats, bulb flats offer better performance in load distribution and structural reinforcement.

-

Marine-grade aluminum troughs: A U-shaped or channel profile used in drainage systems, cable management, and structural components in marine environments. They help guide or support materials while resisting corrosion.

-

Marine Grade Aluminum Square Tube

Marine Grade Square Tube: A type of hollow square aluminum profile used in frameworks, railings, and other structural applications where both strength and corrosion resistance are critical.

-

Marine Grade I-Type Aluminum Profiles

Marine-grade I-beam aluminum: An I-beam or H-beam aluminum profile used in marine applications requiring high strength, typically used in the construction of beams, joists, and structural supports.

-

Marine Grade T-Type Aluminum Profiles

Marine T aluminum is a type of aluminum profile specifically designed for shipbuilding, primarily used for connecting or reinforcing hull parts at a vertical angle.

-

Marine-grade angular aluminum is used for reinforcing edges, frames, and supports in marine structures with L-shaped or angled aluminum profiles. It is valued for its structural support and corrosion-resistant properties.

-

Marine Grade Flat Aluminum refers to flat, rectangular marine aluminum sheets or strips used in structural components, decks, and other flat surfaces on vessels.