Aluminum Pipe Fitting Caps

Need reliable pipe protection? Our aluminum pipe caps offer superior resistance to weather, chemicals, and wear. Choose from standard or custom designs to fit any aluminum piping system. Fast shipping and competitive pricing!

Aluminum pipe cap, also known as aluminum end cap or aluminum pipe plug, is an aluminum accessory used to seal one end of a metal pipe or other tubular items. They can be made by extrusion or machining, available in various sizes and models to fit different pipe diameters and types.

Aluminum pipe cap (i.e., aluminum alloy end cap) is widely used in the marine field, especially in pipeline sealing applications, where it offers significant advantages.

Aluminum Pipe Fitting Caps are fittings used to seal the ends of pipes, typically made of aluminum alloy.

Aluminum Pipe Fitting Caps are pipe fitting accessories used to close aluminum pipe ends, widely used in machinery, hydraulics, pneumatics, construction, and pipeline engineering.

Aluminum Pipe Fitting Caps are essential sealing components in piping systems, primarily used to seal pipe ends and protect the pipeline. Their lightweight and corrosion-resistant properties make them widely used in industrial, construction, and other fields. The specific selection should be based on pipe size, pressure rating, and connection method.

Aluminum Pipe Fitting Caps are fittings used to seal the ends of pipelines, typically made of aluminum alloys such as 6061-T6 or 5083 marine-grade alloys. Their designs include threaded, welded, or clamped types, suitable for different installation needs, ensuring the sealing and integrity of the piping system.

Aluminum pipe caps are protective components used to seal the ends of pipes, tubes, or fittings. They prevent contamination, leakage, and damage, ensuring the integrity of systems in various applications. These caps are made of aluminum alloys, combining durability, lightweight properties, and resistance to environmental factors.

Purchase high-quality aluminum pipe fitting caps for seamless pipeline sealing. These pipe fitting caps are lightweight and durable, preventing contamination and damage. Haomei Aluminum offers various sizes and bulk order options, including OEM services.

Functions of Aluminum Pipe Caps

- Seal the pipe: Prevent water, air, dust, and other impurities from entering the pipe, avoiding internal medium leakage or contamination.

- Protect the pipe ends: Protect pipe cuts from mechanical damage or corrosion during transportation, storage, or maintenance.

- Pressure and corrosion resistance: Aluminum alloy is lightweight and corrosion-resistant, suitable for high-pressure (e.g., compressed air systems) or corrosive environments.

- Temporary sealing: Used as a temporary sealing tool during pipeline construction or maintenance, facilitating subsequent operations.

- Dust and pollution prevention: Seal the pipe ends to prevent dust, moisture, or other pollutants from entering the interior of the pipe.

- Protection: Protect the pipe ends from damage, extending the lifespan of the pipeline.

- Prevent leakage: Used as a temporary or permanent seal to prevent liquid or gas leakage from the pipeline when necessary.

- Decorative purpose: Aluminum pipe caps can be anodized or undergo other surface treatments to match the pipe's color and appearance, enhancing the overall aesthetics of the product.

Materials and Types of Aluminum Pipe Fitting Caps

The materials used are primarily aluminum alloys such as 6061, 6063, which meet the demands for high pressure and thick walls. Typically, 6061-T6 or 6063-T5 aluminum are used because of their strength, weldability, and corrosion resistance.

Common Materials for Aluminum Pipe Fitting Caps

| Aluminum Alloy Series | Typical Grades and Characteristics |

| Pure Aluminum (1xxx Series) | 1100, 1050: Purity over 99%, excellent corrosion resistance but lower strength. |

| Aluminum-Manganese Alloy (3xxx Series) | 3003, 3A21: Manganese is added, offering slightly better strength and corrosion resistance than pure aluminum. |

| Aluminum-Magnesium-Silicon Alloy (6xxx Series) | 6061, 6063: Excellent overall performance, high strength and easy to process, widely used in industrial fields. |

| Aluminum-Magnesium Alloy (5xxx Series) | 5052, 5083: High magnesium content, resistant to seawater corrosion, suitable for marine or chemical environments. |

| High-Strength Aluminum Alloys (2xxx or 7xxx Series) | 2024, 7075: Achieve high strength by adding copper or zinc, but have poorer corrosion resistance and require surface treatment. |

Aluminum Pipe Fitting Caps Materials, Alloys, and Specifications

Aluminum caps are made from several common alloys. 6061-T6 is widely used due to its good strength and weldability;

- 6061-T6 has corrosion resistance, making it suitable for fittings.

- 3003 or 3004 aluminum sheets are commonly used for stamped or spun caps.

In marine environments, high-magnesium 5xxx series alloys (5086-H116, 5083-H321) are preferred because they offer better saltwater resistance.

Aluminum butt-weld caps made from 5086 alloy (marine grade) are rated at Class 150. In comparison, 6061 (6xxx alloy) provides good overall corrosion resistance and strength, while 5083/5086 (5xxx alloys) offer superior seawater resistance.

| Alloy | Composition/Grade | Properties (strength, corrosion) |

| 6061-T6 | Mg-Si alloy (Wrought) | Medium strength, good machinability, weldable. Corrosion-resistant (better than mild steel), used for structural caps. |

| 5086-H116 / 5083-H321 | Mg-rich (Wrought) | High corrosion resistance (especially to seawater), excellent weldability. Preferred "marine-grade" alloy. Resistance ~0.02 mm/yr (vs 0.1–0.2 mm/yr for generic Al). |

| 3003 / 3004 | Al-Mn (wrought) | Lower strength, very good formability. Used for stamped or spun dome caps. Good corrosion resistance but weaker. |

| Aluminum 356 (casting) | Al-Si (cast) | Used for some die-cast caps and couplings. Good castability, moderate corrosion resistance (often anodized). |

| 3000-series (sheet) | Al-Mn | Common for light gauge caps, good corrosion resistance. |

Properties of Different Materials

| Material Type | Typical Grades | Properties |

| Pure Aluminum (1xxx) | 1100 | High ductility, good electrical/thermal conductivity, excellent corrosion resistance but low strength, suitable for low-pressure/non-load-bearing applications. |

| Aluminum-Manganese (3xxx) | 3003 | Moderate strength, better corrosion resistance than pure aluminum, suitable for medium pressure environments. |

| Aluminum-Magnesium-Silicon (6xxx) | 6061-T6 | High strength, easy to process (welding/cutting), resistant to oxidation, widely used in mechanical and construction pipelines. |

| Aluminum-Magnesium (5xxx) | 5052 | Resistant to seawater corrosion, good weldability, strong fatigue resistance, suitable for marine or chemical pipelines. |

| High-Strength Alloys | 7075-T6 | Ultra-high strength (close to steel), but poor corrosion resistance, requires anodizing or coating protection, used in aerospace/military applications. |

Effect of Material on Aluminum Pipe Fitting Caps Performance

| Performance Indicators | Impact of Different Aluminum Alloy Materials |

| Strength and Pressure Resistance | High-strength alloys (7075/2024): Suitable for high-pressure or dynamic load scenarios, but at a higher cost. |

| 6xxx series (6061): Balances strength and machinability, suitable for general industrial piping. | |

| Pure aluminum (1100): Suitable only for low-pressure or decorative uses. | |

| Corrosion Resistance | 5xxx series (5052): Performs best in chlorine environments (such as marine). |

| Pure aluminum/3xxx series: Suitable for ordinary atmospheric environments, but needs to avoid acidic or alkaline media. | |

| 2xxx/7xxx series: Requires anodizing or coating to improve corrosion resistance. | |

| Machinability | 1xxx/3xxx series: High ductility, easy to stamp or cold-form. |

| 6xxx series: Weldable, machinable, suitable for complex structural machining. | |

| 5xxx series: Good weldability, but prone to hardening during cold processing. | |

| Weight and Cost | All aluminum alloys have the advantage of being lightweight (density approximately 2.7g/cm³). |

| Pure aluminum and 3xxx alloys have the lowest cost, while 7xxx alloys are the most expensive. | |

| Temperature Adaptability | 5xxx/6xxx series: Can operate stably between -50°C and 150°C. |

| High-strength alloys (such as 7075): Tend to soften at high temperatures, requiring attention to temperature limits. |

Surface Treatment: Anodizing (enhances corrosion and scratch resistance), powder coating (color customization, increased protection), or regular mill finish.

- Anodizing: Improves corrosion resistance and surface hardness (suitable for 6xxx/7xxx series). Film thickness 10-25μm, enhancing surface hardness (HV > 300) and insulation properties.

- Powder coating/e-coating: Enhances weather resistance and aesthetics (such as for outdoor pipelines).

- Chemical plating: Used for special corrosion protection needs (such as nickel or chrome plating).

- Passivation: Chromate conversion coating, enhancing chemical corrosion resistance.

- Sandblasting/brushing: Ra value 0.8-3.2μm, improves surface roughness to meet specific operational conditions.

Aluminum Pipe Fitting Caps

Aluminum Pipe Caps Specifications and Design

Aluminum Pipe Cap Specifications

- Threaded and non-threaded: Threaded caps (e.g., NPT, BSP) screw onto pipes; non-threaded ones use compression or welding.

- Shape: Domed (for pressure distribution), flat or custom profiles.

- Size: Diameter range from 1/8 inch to several inches; customizable options available.

Aluminum Pipe Cap Design Variations

- Threaded caps: These pipe fittings have internal or external threads (usually conforming to NPT, BSP, or UN standards), allowing them to be screwed onto the pipe, making removal and reinstallation easy.

- Weld-on caps: These caps are designed for permanent applications, welded onto the pipe to provide a secure seal, ideal for long-term installations.

- Sleeve/Push-fit options: Some designs allow a friction fit, making them easy to install and remove, typically used for temporary sealing or insulation applications.

Aluminum Pipe Cap Shape Classifications

- Standard oval shape (EHA/EHB): The curvature radius to short axis ratio is 2:1, ensuring uniform pressure distribution, suitable for medium to low-pressure vessels (such as storage tanks, reactors).

- Butterfly-shaped head (THA/THB): Composed of spherical, flanged, and straight edges, cost-effective but with weaker pressure resistance, commonly used in low-pressure or non-critical equipment.

- Hemispherical shape (HHA/HHB): Best mechanical properties, able to withstand high pressure and alternating loads, commonly used in aerospace and nuclear industries.

- Flat-bottomed head: Simple structure, suitable for normal or low-pressure sealing, commonly used at the pipe ends.

- Cone-shaped head (CHA/CHB): Conical angle of 30°-90°, used for material transition or drainage (such as at the bottom of chemical reactors).

| Cap Type | Features | Applicable Scenarios |

| Flat End Cap | Flat shape, smooth surface. | General sealing needs, without the need to withstand external force or pressure. |

| Domed End Cap | Protruding shape, curved surface, providing additional strength. | Suitable for pipes that need to withstand external force or pressure. |

| Threaded End Cap | Has internal threads, making it easy to connect with externally threaded pipes. | Used in situations where connection to threaded pipes is needed, such as for quick installation or disassembly in piping systems. |

| Flanged End Cap | Equipped with ears or mounting holes, making it easier to fix and install. | Applications requiring fixed end caps, such as mechanical devices where the end cap needs to be secured to prevent loosening or vibration. |

Type and Design Features

- Threaded Connection: Fits with pipes through internal or external threads, suitable for scenarios requiring frequent disassembly.

- Welded Type: Welded and fixed to the pipe end, providing permanent sealing, commonly found in high-pressure systems.

- Quick Lock Type: Uses a clasp or sealing ring design, convenient for installation, suitable for temporary sealing needs.

- Anti-Rolling Design: Some end caps have square edges to prevent the pipe from rolling, making transportation and storage easier.

Aluminum Pipe Cap Connection Methods

Aluminum Pipe Fitting Caps are used to seal pipe openings and come in a variety of connection methods.

- Threaded caps (NPT/NPSM internal threads) can be screwed into standard pipe threads.

- Welded (butt-weld) caps can be welded to the pipe end.

- Camlock (cam groove) caps (commonly referred to as dust caps) can be installed on camlock couplings (DC/D type or F type).

- Flanged caps can be bolted onto ANSI pipe flanges.

These pipe caps are made from various aluminum alloys and are typically suitable for low- to medium-pressure applications (Class 150, approximately 150 psi) in air, water, and oil media.

| Cap Type | Connection | Material (Alloy) | Pressure Rating | Typical Wall (pipe) | Notes |

| Threaded (NPT/NPSM) | Female NPT/NPSM threads (ANSI B1.20.1) | Cast or wrought aluminum (often 6061-T6 or 356 cast; some stamped 3003) | Class 150 (~150 psi) | Match Schedule 40 pipe | Quick to install; typical for light plumbing/marine low-pressure lines. |

| Weld-on (Butt-Weld) | Beveled end for full-penetration weld | Extruded/wrought (6061-T6 common, or 5086/5083 for marine) | Class 150 (~150 psi) | Schedule 40 or 80 pipe wall | Smooth interior after welding; used for maximum flow. |

| Camlock (Dust Cap) | Inserts into cam coupling (Type DC/D, F) | Alloy cast (often 356 or 6061) | Class 150 (~150 psi) (camlock standard ratings) | (N/A) | Seals cam-and-groove fittings; used on dry disconnect lines. Typically supplied with Buna-N gasket. |

| Flanged | Blind flange (bolted) | Plate (usually 6061-T6) | ANSI Class 150 (150 psi) | Plate thickness (~⅜″) | Covers flange face; used on high-viscosity or frequent-service pipes. |

| Push-On (Quick Coupling) | Slip-on coupling (rubber gasket, then clamp-bolted) | Aluminum flange halves + rubber gasket | ~150 psi (varies) | Schedule 40 pipe | E.g. Victaulic-style or Victaulic gasket clamps; allows fast assembly. |

Common Sizes and Wall Thicknesses of Aluminum Pipe Fitting Caps

Aluminum pipe caps are suitable for pipes with standard nominal sizes. Typical size ranges go from very small pipe diameters (⅛ inch NPS) to several inches. For example, marine supplier Haomei Aluminum offers aluminum pipe plugs (pipe caps) suitable for nominal sizes of 1/8 inch, 1/4 inch, 3/8 inch, 1/2 inch, 3/4 inch, and 1 inch. Welded pipe caps for larger pipe diameters are also commonly produced. Generally, pipe caps match the standard outside diameter (OD) of Schedule-40 or Schedule-80 aluminum pipes.

Schedule-40 6061-T6 Aluminum Pipe Dimensions

| Nominal Pipe Size | OD (in) – OD (mm) | Wall Thickness (in) – (mm) |

| ½″ (15 mm) | 0.840″ – 21.34 mm | 0.109″ – 2.77 mm |

| ¾″ (20 mm) | 1.050″ – 26.67 mm | 0.113″ – 2.87 mm |

| 1″ (25 mm) | 1.315″ – 33.40 mm | 0.133″ – 3.38 mm |

| 1¼″ (32 mm) | 1.660″ – 42.16 mm | 0.140″ – 3.56 mm |

| 1½″ (40 mm) | 1.900″ – 48.26 mm | 0.145″ – 3.68 mm |

| 2″ (50 mm) | 2.375″ – 60.33 mm | 0.154″ – 3.91 mm |

| 2½″ (65 mm) | 2.875″ – 73.03 mm | 0.203″ – 5.16 mm |

| 3″ (75 mm) | 3.500″ – 88.90 mm | 0.216″ – 5.49 mm |

| 3½″ (90 mm) | 3.548″ – 90.12 mm | 0.226″ – 5.74 mm |

| 4″ (100 mm) | 4.500″ – 114.30 mm | 0.237″ – 6.02 mm |

Aluminum Pipe Fitting Caps Pressure Ratings and Wall Thickness

Aluminum pipe caps are typically suitable for ANSI Class 150 (150psi) service.

- Aluminum pipe fittings with Schedule 40 wall thickness (including their caps) are used in low-pressure systems.

- Fittings with greater wall thickness, such as Schedule 80, can reach Class 300 (approximately 300psi) under specified conditions.

Due to the relatively soft nature of aluminum, the fittings include a safety factor. Welded pipe caps adopt a beveled edge design for full penetration welding on Schedule 40/80 pipes. Flanged aluminum pipe caps comply with Class 150 specifications. For rubber or gasket-type caps (such as cam-lock or coupling pipe caps), the working pressure is also approximately 150psi, usually limited by the gasket material.

These pipe walls conform to common wall thickness standards (thin wall and thick wall). For high-pressure applications, we also offer thicker wall (Schedule 80) pipe caps. The surface thickness of flanged pipe caps is typically the same as that of standard ANSI B16.5 Class 150 flanges (about 3/8 inch or 10 mm).

aluminum fittings pipe caps

Core Features of Aluminum Pipe Fitting Caps

- Corrosion Resistance: The oxide film formed on the surface of aluminum alloy naturally resists corrosion. Marine-grade alloys (such as 5083) can resist seawater, salt spray, and electrochemical corrosion after anodizing or coating treatment.

- Lightweight and High Strength: With a density of only 1/3 that of steel, it is suitable for weight reduction requirements in ships. After heat treatment, strength is enhanced, allowing it to withstand high pressure (e.g., deep-sea pipelines).

- Sealing: Precision machining ensures no leakage under high pressure and vibration conditions, meeting standards such as IP67.

- Extreme Environment Resistance: Capable of withstanding a temperature range from -50°C to 150°C and UV radiation.

- Strength and Pressure Resistance: Optimized alloy composition enables aluminum pipe caps to meet the sealing requirements of high-pressure pipelines in marine engineering, and comply with pressure vessel standards.

Aluminum Pipe Caps Applications

Aluminum pipe caps are widely used in various industries, including but not limited to construction, automotive manufacturing, furniture manufacturing, medical equipment industries, etc. Depending on the application scenario and requirements, different grades and types of aluminum can be used to manufacture aluminum pipe caps to ensure their performance and durability.

Aluminum Pipe Cap Applications in the Marine Industry

| Application Area | Description |

| Seawater Desalination Systems | Aluminum pipe caps are used at the ends of pipes and pressure vessels in seawater desalination plants. Due to their corrosion resistance, they can withstand the erosion from high-salinity seawater for extended periods. The lightweight design also reduces the overall load of the system. |

| Subsea Oil/Gas Pipelines | In deep-sea pipeline systems, aluminum pipe caps are used to isolate different sections or seal off abandoned pipelines. Their high-pressure resistance (enhanced by alloy strengthening) allows them to withstand deep-water pressures and prevent leaks, thus protecting the marine environment from contamination. |

| Ship Ballast Water Systems | Aluminum pipe caps are commonly used to seal pipes in ship ballast tanks to prevent seawater leakage, which could lead to corrosion of the tank. Additionally, the low density of aluminum reduces the ship's weight and enhances its sailing efficiency. |

| Offshore Platform Equipment | Aluminum pipe caps are used in key areas such as cooling systems and fire-fighting pipelines on drilling platforms or Floating Production Storage and Offloading (FPSO) units. Their resistance to salt-spray corrosion extends the life of the equipment. |

| Marine Research Instruments | Sealing compartments or sensor pipelines of underwater detection equipment (such as ROVs, AUVs) use aluminum pipe caps to ensure stable operation of instruments in high-pressure, low-temperature environments. |

Marine Adaptability Design

- Prevents Galvanic Corrosion: Uses insulating gaskets or coatings to avoid contact with dissimilar metals (e.g., steel) that could cause corrosion.

- Cathodic Protection Compatibility: Compatible with the overall cathodic protection system of platforms or vessels, extending service life.

- Quick Disassembly Structure: The clasp design facilitates operation by divers or robotic arms, reducing underwater working time.

Which industries use aluminum pipe caps

- Construction Engineering: Used in aluminum piping systems within buildings.

- Mechanical Engineering: Used in hydraulic systems, pneumatic systems, or other mechanical devices.

- Automotive Industry: Commonly found in automotive cooling systems, oil pipe systems, etc.

- Electronic Equipment: Used for sealing in heat dissipation systems or piping in electronic devices.

- Industrial Pipelines: Such as compressed air systems, hydraulic pipelines, chemical pipelines, where sealing and pressure resistance are required.

- Construction and Machinery: Used in air conditioning systems, fire protection pipelines, or pipe end protection in mechanical equipment.

- Aerospace and Automotive: The lightweight properties of aluminum make it suitable for weight-sensitive fields.

Recommended Application Scenarios

- Construction/Decorative Pipelines: 1100 or 3003 (low cost, easy to process).

- Industrial Fluid Systems: 6061-T6 (strength, pressure resistance, and processability balanced).

- Marine/Chemical Environments: 5052 or 5083 (corrosion resistance prioritized).

- Aerospace/Military: 7075-T6 (strength prioritized, with surface treatment).

Aluminum Pipe Cap Advantages

| Advantages | Description |

| Corrosion Resistance | Aluminum pipe caps have natural rust and corrosion resistance. The oxide layer formed on their surface effectively protects the aluminum alloy from damage caused by air, water, and chemicals, making them suitable for long-term use in marine environments, chemical plants, and other humid, corrosive settings. This significantly extends the service life of the components. |

| Lightweight and Durable | Aluminum pipe caps are lightweight, significantly reducing the overall load of the system. This feature makes them highly popular in aerospace, construction, and industrial pipelines, without sacrificing their durability and strength, ensuring system stability and reliability during use. |

| Cost-Effective | Aluminum pipe caps are generally cheaper than stainless steel or other metal products, making them a cost-effective solution. Despite the lower price, aluminum caps still provide strength and durability comparable to other metal materials, making them an ideal budget-friendly product, especially for projects with limited budgets. |

| Thermal Conductivity | Aluminum pipe caps have excellent thermal conductivity. Their high thermal conductivity makes them especially suitable for systems that require temperature regulation, such as cooling pipelines and heat exchange systems. They can quickly conduct heat, maintaining temperature balance efficiently, making them suitable for various industrial applications. |

| Pressure Rating | Aluminum pipe caps are designed to withstand various pressure ratings as needed. Some high-strength aluminum alloy caps are particularly suitable for high-pressure environments, effectively sealing pipe ends to prevent leaks and maintain system integrity. They perform excellently in applications with high-pressure sealing requirements, showing superb stability and reliability. |

| Aesthetics | Aluminum pipe caps offer a variety of surface treatment options, from rolled finishes to anodized coatings, providing a good visual effect. These surface treatments not only enhance the corrosion resistance of the caps but also offer a clean and smooth appearance for exposed pipelines, enhancing the overall aesthetic and professional appearance of the installation. |

Aluminum Pipe Fitting Caps Standards and Certifications

Complies with standards from classification societies such as DNV GL, ABS, as well as ASTM B209 (Aluminum Alloy Plates) and ISO 14713 (Corrosion Protection Design) regulations, ensuring the marine applicability of materials and processes.

Maintenance and Economic Efficiency

The design lifespan can reach over 20 years, reducing replacement frequency and maintenance costs by 40% compared to traditional materials, especially suitable for ocean-going ships and offshore facilities.

Aluminum Pipe Fitting Caps, with their lightweight, corrosion resistance, and high reliability, have become key components for pipe sealing in marine engineering, playing an important role in enhancing system safety and operational efficiency.

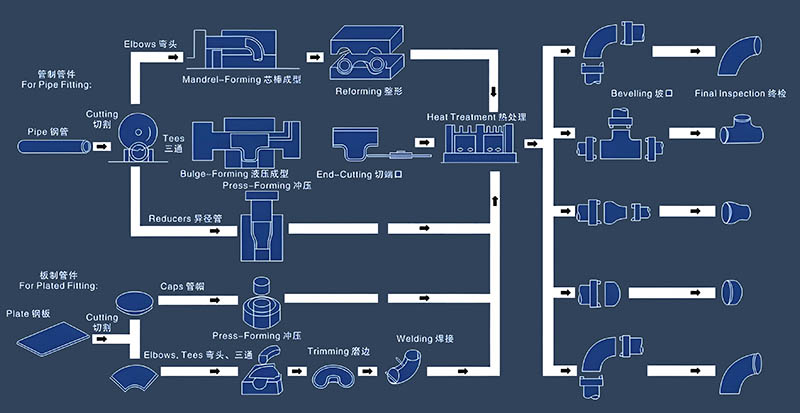

Aluminum Fittings Pipe Caps Manufacturing Process and selection

Aluminum Fittings Pipe Caps Manufacturing Process

Manufacturing: They are precision machined (or in some applications, die-cast), with strict tolerances to ensure proper fit and reliable sealing. Some products may also undergo surface treatments such as anodizing or polishing to enhance durability and appearance.

- Casting: Suitable for complex shapes; cost-effective for large-volume production.

- Machining: Precision manufacturing with strict tolerances.

- Stamping/Forming: Used for thinner, lighter caps.

- Cold Stamping/Forming: Suitable for thin plates with thickness < 12mm, mold precision ±0.1mm, high batch production efficiency.

- Hot Spinning/Forming: For thick plates (>15mm) or large diameters (>3m) caps, the process involves heating to 300-400℃ to reduce deformation resistance.

- Segmental Welding: For ultra-large caps, a petal-style welded assembly is used, requiring 100% X-ray inspection of the weld seams.

- Precision Machining: CNC turning ensures flange sealing surface flatness < 0.05mm, roughness Ra ≤ 1.6μm.

Considerations for Selecting Aluminum Pipe Caps

When selecting aluminum pipe fittings caps, it is necessary to comprehensively evaluate pressure requirements, corrosive environment, processing methods, cost budget, and temperature conditions. For example:

- Standard water pipe caps can use 6061;

- Marine platform pipelines require 5052;

- High-stress components are recommended to use 7075 (with surface treatment).

Selection Considerations

- Pipe Size: Match the internal/external diameter and thread type (if applicable).

- Environment: Choose surface treatment based on exposure (e.g., saltwater anodizing).

- Pressure/Temperature: Verify operational safety grade.

- Regulatory Requirements: Ensure compliance with industry-specific standards.

Advantages of Aluminum Fittings Pipe Caps Over Alternatives

- vs Stainless Steel: Aluminum is lighter, more cost-effective, and has better seawater corrosion resistance than regular stainless steel (e.g., 304). However, for high-stress environments, high-strength aluminum alloys (e.g., 6061-T6) should be selected.

- vs Titanium Alloys: Although titanium has superior performance, it is expensive. Aluminum is more cost-effective in most medium-to-low-pressure scenarios.

- vs Composite Materials: Aluminum has better mechanical strength and recyclability, meeting the environmental requirements of marine engineering.

- vs Plastic: Aluminum has higher strength and better heat resistance.

Why Choose Haomei Aluminum as Your Supplier for Aluminum Fittings Pipe Caps?

Professionalism and Reliability

- Rich Industry Experience: Haomei Aluminum specializes in aluminum processing for many years, with deep technical expertise in the design and production of pipeline sealing fittings, ensuring precise fulfillment of various scenario needs.

- Material Advantage: We select high-purity aluminum materials (such as 6061, 6063, etc.), ensuring lightweight products with strong corrosion resistance and excellent mechanical properties, suitable for a variety of fields such as industrial, construction, and automotive.

- Customization Services: We provide various size and specification options, support bulk orders and OEM customization, and flexibly adapt to customers' special design needs.

- Quality Certification Assurance: Our production processes comply with international standards such as ISO 9001, and products undergo strict testing to ensure batch consistency and reduce customers' procurement risks.

- Cost and Efficiency Balance: With large-scale production capabilities and optimized supply chain management, we offer high-cost performance products and shorten delivery times.

Haomei Aluminum Ensures the Processing Quality of Aluminum Fittings Pipe Caps

| Measures | Description |

| Advanced Equipment and Process Standardization | Haomei Aluminum uses high-precision CNC machines, automated stamping lines, and spectrometers to ensure the processing accuracy and material composition of aluminum fittings pipe caps meet the standards. These devices effectively guarantee product consistency and high-quality requirements in terms of size and material. Standard Operating Procedures (SOPs) are also established to regulate the details of each process, reduce human errors, and improve consistency in the production process. |

| Strict Process Monitoring | During production, Haomei Aluminum implements a strict quality control system. First, the first articles are subjected to dimensional, sealing, and pressure testing to ensure compliance with drawings and technical requirements. Throughout production, laser measurement devices and leak detection equipment are used to monitor critical parameters in real-time, ensuring every product meets quality standards, intercepting non-conforming products promptly, and ensuring product consistency and reliability. |

| Multi-dimensional Testing Methods | To ensure the quality of aluminum fittings pipe caps, Haomei Aluminum adopts multiple testing methods. Key dimensions are precisely measured using 3D coordinate measuring machines (CMM), while pressure tests, salt spray tests, and other environmental simulation tests are conducted to verify the product's corrosion resistance and fatigue resistance. To ensure appearance quality, visual and tactile inspections are also performed to ensure the surface is smooth without scratches or cracks, further ensuring the product's integrity and aesthetics. |

Haomei Aluminum, with its mature processing technology, strict quality control system, and flexible customization capabilities, has become a trusted supplier of aluminum fittings pipe caps. Its products balance lightweight, durability, and high sealing performance, meeting the high standards of pipeline protection in industries such as construction and industrial sectors. For more details or customized solutions, please contact the Haomei team for professional support.

Customization

- Customized sizes, shapes, and finishes available.

- Laser engraving for marking or branding.

Aluminum pipe fittings caps are a versatile and durable solution for sealing pipeline systems. The unique properties of aluminum make it well-suited for various industries, making it the first choice for engineers focused on performance, lifespan, and cost-effectiveness. Always select based on specific application requirements to ensure optimal performance.