Aluminum/steel clad plate

As a leading manufacturer of aluminum/steel clad plates, we provide precision-engineered composite materials with exceptional corrosion resistance, structural strength, and thermal conductivity.

Aluminum/steel clad plate is a composite material composed of an aluminum alloy layer and a steel layer metallurgically bonded together. This bimetallic plate retains the inherent properties of each metal: aluminum offers lightweight and corrosion resistance, while steel provides structural strength and durability.

The aluminum/steel clad plate is a composite material made by metallurgically bonding an aluminum alloy layer and a steel layer. This bimetallic plate retains the inherent properties of each metal: aluminum is lightweight and corrosion-resistant, while steel provides structural strength and durability.

The aluminum/steel clad plate is a laminated composite material formed by tightly bonding aluminum (or aluminum alloys) with steel (such as carbon steel, stainless steel) using special processes (e.g., explosive welding, hot-rolled bonding, or cold-rolled bonding). The two metals form a metallurgical bond at the interface, combining the excellent properties of both aluminum and steel.

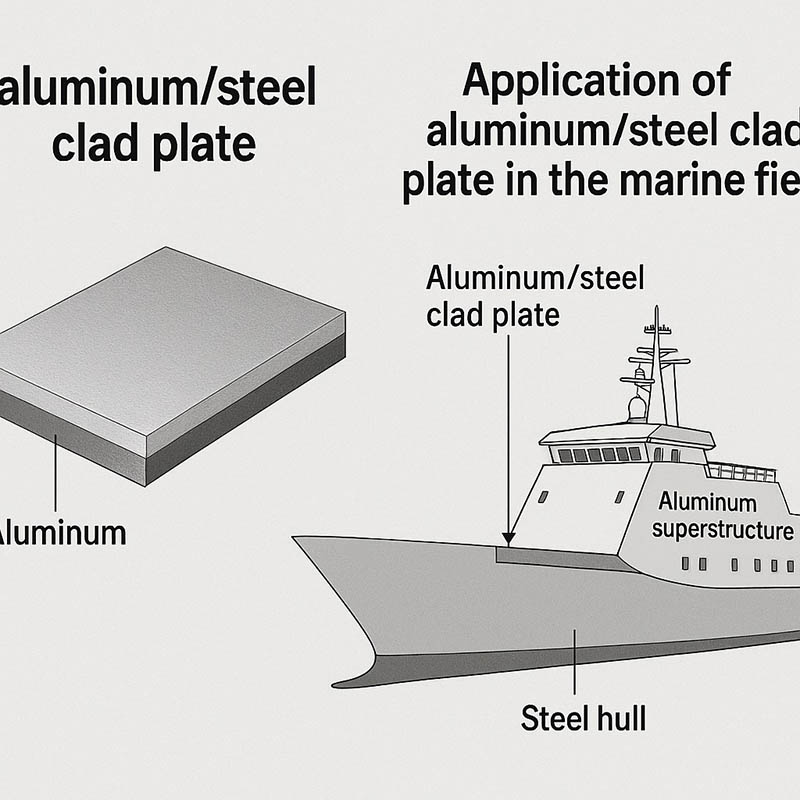

Surface treatments (such as brushing and sandblasting) and controlled heating (300–500°C) are crucial for removing oxide films and promoting diffusion during the bonding process. The resulting clad plate exhibits excellent corrosion resistance, comprehensive mechanical properties, and enhanced thermal/electrical conductivity, making it an ideal choice for marine transition joints. These joints bond aluminum superstructures to steel hulls in tugboats, ferries, yachts, and motorboats, where static loads dominate and fatigue stress is minimal.

As a leading manufacturer of aluminum/steel clad plates, we provide precision-engineered composite materials with exceptional corrosion resistance, structural strength, and thermal conductivity. Ideal for aerospace, marine, and construction applications. Request a quote for certified, custom-sized solutions today.

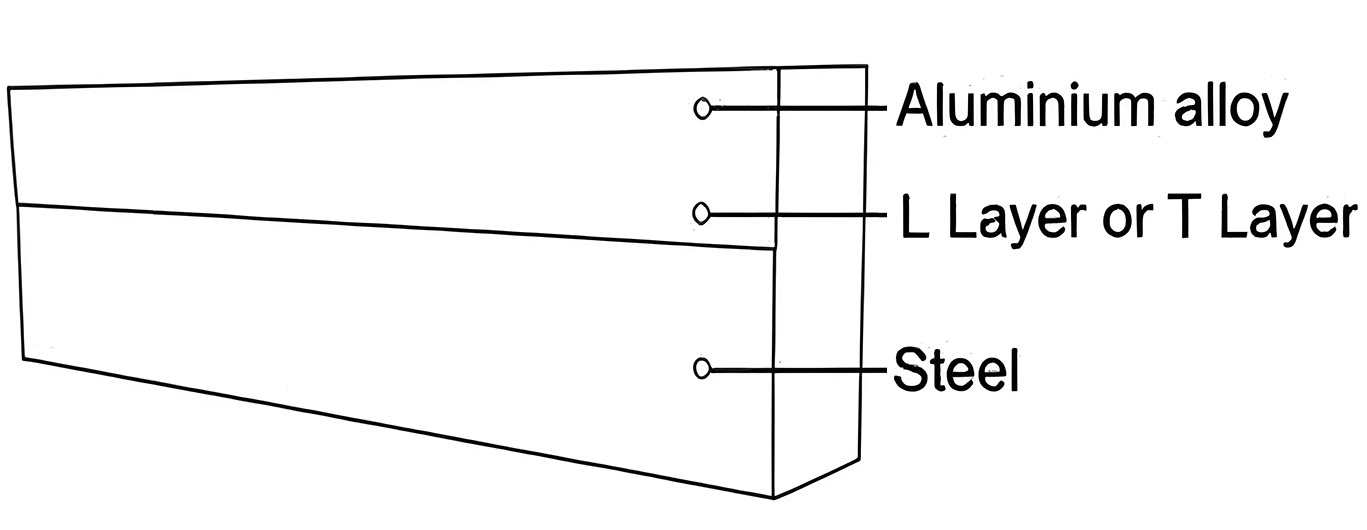

Aluminum/steel clad plate Material and Structure

- Material Composition: Composed of a steel layer and an aluminum layer bonded through specific processes, combining the high strength (wear resistance, pressure resistance) of steel with the lightweight and corrosion-resistant advantages of aluminum.

- Structural Design: Typically employs "explosive welding technology" or "roll bonding process" to form a metallurgical bonding layer, ensuring a tight interface bond and avoiding delamination risks.

The clad plate consists of two primary material layers: an aluminum alloy cladding and a steel substrate, with complementary properties.

- The steel substrate is usually made of carbon steel to enhance structural strength or stainless steel to improve corrosion resistance.

- Cladding alloys include commercially pure aluminum for ease of bonding, 5xxx series aluminum for enhanced strength and corrosion resistance, or 6xxx series aluminum for structural applications.

Performance Combination

- Aluminum layer: lightweight, corrosion-resistant (especially resistant to atmospheric/acid-alkali corrosion), good thermal and electrical conductivity.

- Steel layer: high strength, wear-resistant, strong support capability.

- The combination of both reduces the limitations of traditional single-material structures (e.g., pure aluminum's insufficient strength, steel's tendency to rust).

| Performance | Description |

| Corrosion resistance (aluminum side) | The aluminum layer has excellent corrosion resistance, especially in harsh environments such as the shipbuilding industry or chemical industries. |

| Strength (steel side) | The steel layer enhances the strength and structural integrity of the composite plate, allowing it to bear heavy loads or stresses, making it suitable for applications requiring high load-bearing capacity. |

| Lightweight (aluminum side) | Compared to pure steel, the aluminum layer reduces the overall weight, which is highly beneficial for aerospace, automotive, and transportation applications, reducing structural weight. |

| Thermal and electrical conductivity (aluminum side) | The aluminum side has good thermal and electrical conductivity, making it suitable for heat exchange applications, such as in electronics, radiators, and other fields. |

| Cost-effectiveness | Compared to using pure aluminum or pure steel to manufacture the entire structure, the composite plate provides higher versatility in performance while achieving the combination of multiple properties at a lower cost. |

Explosive bonded transition joint (steel/aluminum) 5083/1060/B

| Description | Material | Maximum thickness (mm) |

| 1st layer - base material | Grade B | 18 |

| 2st layer - intermediate | 1060/O | 4 |

| 3rd layer - cladding material | 5083/O | 6 |

Aluminum/steel clad plate Mechanical properties specification

| Structural Transition Joint | Shear strength As bonded | Through thickness tensile strength As bonded & After 15min at 320°C | Through thickness tensile strength on welded assembly As bonded |

| 5083/1060/B | min. 55N/mm² | min. 60N/mm² | min. 55N/mm² |

Haomei Aluminum/steel clad plate

| Types of products | Main materials | (mm) Product specifications(mm) | Product standard | Application area |

| Aluminum/steel clad plate | 1A97, 1A93, 1A90, 1A85, 1070, 1060, 5083 | 1~14/6~80x | GB/T 8546-2007 | Electrolytic aluminum, transition joints, naval vessels, aerospace, instrumentation, cryogenic engineering, etc. |

| Q235B, CCSB, Q245R, Q345R, 15CrMoR, 16Mn, 20MnMo, 15CrMo, 109MnNiDR, 16MnD, 09MnNiD | <1000x<4000 |

Core Characteristics of Aluminum/steel Clad Plate

- Lightweight: High aluminum content significantly reduces overall weight, making it suitable for weight-sensitive applications such as ship superstructures.

- Corrosion Resistance: The aluminum layer is naturally resistant to seawater corrosion, extending joint lifespan and reducing maintenance needs.

- Adaptability to Low Stress: Suitable for applications with no significant tearing/fatigue stress (such as small and medium-sized vessels), with flexible designs to mitigate thermal expansion differences.

- Strength: The steel component provides structural integrity for hulls and load-bearing areas.

| Property | Description |

| Mechanical Properties | The strength of the composite material is mainly determined by the steel substrate, while the aluminum layer offers ductility and toughness. |

| Corrosion Resistance | The aluminum cladding protects the steel core from marine and atmospheric corrosion, prolonging service life in harsh environments. |

| Thermal and Electrical Conductivity | The aluminum layer provides high thermal and electrical conductivity, beneficial for heat exchangers and grounding applications. |

| Fatigue and Tearing Considerations | Although the composite interface is metallurgically bonded, its fatigue durability is lower than that of monolithic materials; therefore, clad plates are best suited for static or low-cycle applications with minimal tearing loads. |

Aluminum/steel clad plate in Marine Applications

The application of aluminum/steel clad plates in the marine industry is an excellent example of combining the advantages of both materials to address the challenges of such environments. Aluminum’s inherent properties (corrosion resistance, lightweight) and steel’s inherent properties (strength, durability) make the composite plate an ideal choice for various marine applications.

Aluminum/steel clad plates are commonly used in the shipbuilding industry, where aluminum provides seawater corrosion resistance, while steel provides the strength required to withstand marine pressures. Such applications include hull structures (reducing weight + corrosion protection) and seawater pipelines.

Specific Applications in the Shipbuilding Industry

Hull and Structure

- Hull construction: The combination of aluminum's corrosion resistance and steel's strength makes the composite plate an ideal choice for the outer layer of the hull. Steel provides the necessary structural strength, while aluminum offers seawater corrosion resistance, especially in coastal and open sea environments.

- Corrosion protection for steel hulls: Steel, due to its high strength, is often used for the internal structure of the hull, but aluminum is applied to the exposed surfaces to prevent corrosion. This combination extends the service life of the ship and reduces maintenance costs.

- Superstructure and decks: Composite plates are also used in the construction of ship decks, superstructures, and other ship components exposed to harsh marine environments.

Marine Barges and Platforms

- Offshore platforms: Aluminum/steel clad plates are used in the construction of offshore oil and gas platforms, which require aluminum's corrosion resistance and steel's structural strength to withstand harsh marine conditions.

- Barges: In marine transportation, barges used for transporting goods across waterways also benefit from composite plates. Aluminum helps prevent steel from degrading due to long-term exposure to water, while steel provides the strength needed for carrying heavy loads.

Marine Vehicles (Boats and Yachts)

- Luxury yachts: High-end yachts use aluminum/steel clad plates, combining aesthetics (from the surface treatment of aluminum) with strength and stability (from the steel). The lightweight aluminum also helps improve speed and fuel efficiency.

- High-speed commercial vessels: Aluminum/steel clad plates are used in high-speed commercial vessels, such as ferries, due to their high strength-to-weight ratio. Aluminum's lightweight properties allow for higher speeds, while steel ensures that the vessel can withstand high-impact forces.

Propeller Shafts and Rudders

Corrosion resistance of ship components: Propeller shafts and rudders are often subjected to severe corrosion, especially in seawater. These parts can be covered with an aluminum cladding layer to prevent corrosion while maintaining the required strength and durability of these critical components.

Marine Containers and Storage Tanks

- Cargo hold linings: The aluminum side is used for lining the cargo holds or storage tanks of ships and barges transporting corrosive materials, chemicals, or foodstuffs. It prevents corrosion while maintaining structural integrity.

- Tankers: For transporting chemicals, oils, or other sensitive materials, aluminum/steel clad plates are used in the internal tanks or outer shells of ships, ensuring corrosion resistance both inside and out while maintaining the structure strong enough to handle the materials being transported.

Advantages of Aluminum/Steel Clad Plate

- Combines the benefits of both metals without the need for bulky mechanical fasteners.

- Cost-effective: Only the aluminum layer needs to be used in critical areas (such as the corrosion-resistant surface), reducing the overall cost of full aluminum.

- Design flexibility: The thickness ratio of aluminum to steel can be adjusted (e.g., aluminum layer can be 10-50%).

- Environmentally friendly: Reduces the use of corrosion-resistant coatings (aluminum naturally resists corrosion), extending the material’s lifespan.

- Simplifies construction by directly welding or connecting in specific settings.

Common Issues and Mitigation Measures of Aluminum/Steel Clad Plate

- Galvanic corrosion: Can be addressed through insulating coatings, transition materials (such as bimetallic lugs), or protective sealants to minimize electrolyte exposure.

- Thermal expansion differences: Managed through design flexibility (e.g., expansion joints) and stress distribution analysis.

- Bonding integrity: Quality control during manufacturing ensures interface strength.

Limitations of Aluminum/Steel Clad Plate

- Not suitable for high-stress areas (e.g., ship keels) due to potential interface fatigue.

- Requires careful design to avoid cracking or moisture retention at joints.

Aluminum/steel clad plates offer a practical solution for ship applications focusing on lightweight and corrosion resistance. Their use in low-stress transitions balances performance and practicality, but engineers must consider material incompatibilities during the design phase.

Quality Control of Aluminum/Steel Clad Plate

To ensure safe use of aluminum/steel clad plates in low-stress environments, Haomei implements strict quality control throughout the entire process from raw material to delivery, covering the following aspects:

Raw Material Control

Haomei rigorously inspects incoming aluminum and steel plates to confirm that their composition, surface condition, and flatness meet standards, ensuring subsequent composite quality.

Surface Pretreatment

Haomei performs cleaning, roughening, and acid pickling on aluminum and steel surfaces to enhance interface bonding capability, laying a foundation for roll bonding.

Roll Bonding Process Control

During the bonding process, Haomei precisely controls temperature, pressure, and rolling speed to avoid interface delamination or bubbles, ensuring strong adhesion.

Heat Treatment

Haomei conducts heat treatment according to process requirements to improve interface diffusion strength and overall stability of the clad plate.

Quality Inspection

- Interface bonding strength test: Peel or shear tests are used to confirm strong bonding.

- Corrosion resistance test: Salt spray testing is used to examine interface sealing and corrosion resistance.

- Visual inspection: Products with cracks, delamination, or impurities are rejected.

- Mechanical property testing: Ensures tensile, bending, and other parameters meet application requirements.

Manufacturing Process of Aluminum/Steel Clad Plate

Aluminum/steel clad plates are typically manufactured using solid-state bonding techniques, which enable joining without melting the metals. Explosive welding (explosive cladding) is widely used: a thin aluminum "flyer plate" is accelerated by an explosion and rapidly impacts the steel substrate, forming a high-velocity weld seam with a characteristic wavy interface. As no bulk melting occurs, the properties of the base metals are retained. Explosive cladding allows for bonding over large areas and between alloys with significant differences (such as large thermal expansion mismatches). The resulting joints are extremely strong with minimal heat-affected zones, although surface irregularities and localized melting may occur. Post-weld hot rolling is commonly employed to flatten the plate and improve bond uniformity.

Aluminum/steel clad plates combine the high strength and stiffness of steel with the low density and corrosion resistance of aluminum. In general, the mechanical strength of the clad plate resembles that of the steel core, while the conductivity and weight-saving characteristics resemble those of the aluminum core.

Structural transition joints are manufactured using explosive welding.

Cladding Process:

- Explosive bonding: Uses explosive shock waves to bond steel and aluminum plates under high pressure, suitable for complex shapes and large joints.

- Roll bonding: High-temperature rolling facilitates atomic diffusion bonding of steel and aluminum plates, suitable for mass production.

Welding Process:

- Uses Gas Metal Arc Welding (GMAW) or Gas Tungsten Arc Welding (GTAW), along with aluminum-based filler wires such as ER5183 to ensure welding quality on the aluminum side.

- The steel side needs to be pre-coated with nickel, zinc, or similar to reduce the formation of intermetallic compounds and improve welding reliability.

| Process Type | Description | Applicable Situation |

| Explosive Welding | Uses explosive energy to make metals collide at high speed, creating high temperatures and pressures that form a strong metallurgical bond. | Suitable for the production of thick plates requiring high-energy impact. |

| Hot Rolling Composite | At high temperature and pressure, aluminum and steel metals are rolled together to form a strong metallurgical bond at the interface. | Efficient and suitable for large-scale production, applicable to medium-thick plates. |

| Cold Rolling Composite | Aluminum and steel are combined through large deformation rolling, usually done at room temperature, with the bonding force between the metal layers achieved mechanically. | Suitable for thin plate production, more efficient, and reduces the need for heat treatment. |

- Rolled composite: The most commonly used method, where aluminum and steel layers are rolled together at high temperature and pressure, forming a strong bond.

- Explosive welding: A more specialized method using explosives to bond the two materials together, creating a metallurgical bond with strong resistance to separation.

Production Steps

Surface Treatment

Before bonding, both aluminum and steel surfaces must be brushed or sandblasted to remove native oxides and contaminants, ensuring intimate metal-to-metal contact.

Preheating and Bonding Parameters

- The coated assembly is heated in air to about 300–500°C to promote oxide formation and fracture during rolling, enhancing mechanical interlocking.

- Subsequent hot rolling is performed with an elongation ratio typically of 1–3% relative to the clad layer to consolidate the bond.

Post-treatment

The clad plates may require straightening, trimming, and sometimes stress-relief annealing to optimize flatness and residual stress distribution.

Aluminum/steel clad plate Specifications and Industry Standards

International standards for aluminum/steel clad plates are not as widespread as those for stainless steel clads, but some standards exist, especially in naval applications.

Classification societies (such as Lloyd’s Register, CCS) issue material certificates (e.g., Lloyd’s 3.2) for such clad plates.

In practice, aluminum/steel clad plates are usually certified according to marine or industrial steel plate standards, with additional requirements for aluminum cladding. Common material specifications include: 1000 series aluminum (pure aluminum) or 5xxx marine alloys (e.g., 5083, 5456) clad onto structural steels (e.g., Q235/Q345, ASTM A36/DH36, A516 grades).

A common aluminum/steel clad configuration involves cladding 1050 or 5083 aluminum onto marine-grade steels such as Grade D or Grade A. Sometimes, a thin titanium interlayer is used to improve bonding at high temperatures.

Additional Applications of Aluminum/steel clad plate

Shipbuilding and offshore engineering are the main application areas: clad “transition joints” allow lightweight aluminum superstructures or decks to be welded directly onto steel hulls (avoiding the need for rivets or bolts).

Aluminum/steel clad plates are suitable for areas requiring the structural strength of steel combined with the light weight, thermal/electrical conductivity, or corrosion resistance of aluminum.

- In industrial settings, clad plates are used in cryogenic tanks and piping (e.g., LNG systems), taking advantage of aluminum’s toughness at low temperatures.

- Clad plates are also widely used in power and process plants: for example, aluminum/steel clad heat exchangers or condensers utilize aluminum’s high thermal conductivity and corrosion resistance alongside steel’s strength. They are also used in the construction and automotive industries: vehicles (especially trains or railcars) use aluminum/steel clad plates to provide corrosion-resistant bodies or enclosures.

- Consumer goods also employ aluminum/steel clad plates—for example, heating elements in cookware and household appliances benefit from aluminum’s conductivity and steel’s magnetic/structural properties. In power transmission, aluminum-clad steel is used as a high-strength, corrosion-resistant conductor.

- Defense/armor applications utilize steel-clad aluminum or dual-hardness clads to create armor plates with a hard impact face and a ductile backing.

Marine Engineering: Steel–Aluminum Joints

In marine environments, aluminum/steel clad plates are mainly used as structural transition joints between steel hulls and aluminum superstructures. Their advantages and challenges are evident:

- Advantages: Clad joints enable direct welding between steel and aluminum without the use of heavy mechanical fasteners. This reduces weight and increases reliability. The welded clad layer provides continuous stress transfer (no localized bolt holes), and each metal retains its properties (steel maintains strength; aluminum maintains light weight).

- Corrosion/environmental: A key issue is galvanic corrosion—steel is more inert than aluminum in seawater, so any exposed joint area could accelerate aluminum corrosion. However, modern clad joints, due to their tightly bonded interfaces, can avoid crevice corrosion.

- Mechanical properties: Under seawater and shipborne loads, aluminum clad joints perform well. As the clad interface remains intact, they can withstand different thermal expansions (aluminum and steel expand differently under engine heat). The linear welds provided by clad plates also simplify design: for example, whole panels can be welded into frames, bulkheads, or decks connecting steel and aluminum sections.

Aluminum/steel clad plates provide ship engineers with a reliable method for joining dissimilar metals. They deliver steel’s strength where needed and aluminum’s lightweight corrosion resistance on exposed surfaces. Although galvanic corrosion must be managed (via coatings and design), in practice these clad joints typically outperform bolted connections—after initial oxidation, self-sealing oxides and protective claddings provide significant corrosion resistance. As a result, aluminum/steel transition joints have become standard components in modern superstructures, high-speed ferries, and other marine applications where lightweight and durability are critical.

Aluminum/steel clad plates are used in ships, aerospace structures, pressure vessels, pipelines, architectural panels, and any situation where a durable connection between light and heavy metals is needed.

Aluminum/steel clad plate Precautions

Fatigue Stress Considerations

When designing transition joints, cyclic loading should be minimized; adequate fillets and uniform support should be adopted to reduce stress concentration at the edges of the clad interface.

Operating Temperature Limitations

Operating temperatures above the bonding process range (300–500 °C) may reduce the intermetallic compound layer strength and overall bond integrity; for exact limit values, please refer to the material datasheet.

Other Fields where Aluminum/Steel Clad Plate is Applied

- Aerospace: Used for manufacturing lightweight yet strong components, where aluminum provides corrosion resistance and weight reduction, and steel provides strength.

- Construction: Used in structural applications that require both strength and environmental resistance, such as curtain walls and roofs (aluminum for aesthetics + steel for support).

- Chemical industry: Used for heat exchangers and other equipment exposed to corrosive environments, fully utilizing aluminum’s chemical resistance and steel’s strength.

- Automotive: Clad plates can be used to manufacture components that require both weight reduction (aluminum) and strength (steel).

- Power electronics: Battery housings (conductive + rust-resistant), grounding materials.

The potential difference between aluminum and steel may cause galvanic corrosion, so long-term contact with electrolytic environments should be avoided.

When processing, attention must be paid to the physical differences between the two metals (such as melting point, thermal expansion coefficient), as these may affect welding and cutting processes.