5456 5454 5754 Marine Grade Aluminum Bar

5456 5454 5754 Marine Grade Aluminum Bars undergo a rigorous testing and certification process to ensure they meet the stringent requirements of the marine environment. 5456 5454 5754 aluminum alloy has excellent corrosion resistance and is ideal for use in salt water environments where traditional metals will degrade rapidly.

5456 5454 5754 Marine Grade Aluminum Bar has certification from CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and its quality fully complies with world marine grade standards.

The specification of 5456 5454 5754 marine grade aluminum rods

| Alloy | 5456 5454 5754 |

| Temper | O, H112 |

| Diameter | 8-320MM |

| Length | 1000mm-6000mm |

| Standard | GB/T 26006-2010 GB/T14846-2008 GB/T6892-2015 EN 755 |

5456 5454 5754 Marine Grade Aluminum Bar Performance

5456 Marine Grade Aluminum Bar

5456 aluminum alloy is known for its superior strength and weldability, making it the first choice for marine applications requiring structural integrity and reliability. The composition of 5456 rods is mainly composed of aluminum, magnesium and manganese. It has excellent corrosion resistance and mechanical properties and is suitable for various marine structures, including hulls, decks and superstructures. Additionally, 5456 aluminum rods have high fatigue strength, ensuring longevity and durability in harsh marine environments.

5454 Marine Grade Aluminum Bar

Similar to 5456, 5454 aluminum alloy is prized for its corrosion resistance and weldability, making it a primary material in the marine engineering sector. Characterized by its high strength and formability, 5454 bar is widely used in the construction of ships, offshore platforms and desalination plants. The alloy's ability to withstand long-term exposure to salt water, coupled with its ease of fabrication, makes it an indispensable material in marine applications where performance and longevity are required.

5754 Marine Grade Aluminum Bar

5754 aluminum alloy combines strength, corrosion resistance and formability, making it an excellent choice for marine-grade applications. The composition of alloy 5754 rods contains aluminum, magnesium and trace amounts of chromium, providing excellent resistance to corrosion in seawater and atmospheric conditions, ensuring optimal performance in marine environments. Common applications for 5754 aluminum rod include shipbuilding, shipbuilding and marine infrastructure, where reliability and durability are critical.

5456 5454 5754 Marine Grade Aluminum Bar Advantages

The use of 5456, 5454 and 5754 aluminum rods in marine construction offers many advantages over alternative materials.

1. Excellent corrosion resistance extends the service life of marine structures and reduces maintenance costs and downtime.

2. The lightweight nature of aluminum makes it easier to handle and install, helping to improve overall project efficiency.

3. Aluminum’s recyclability is in line with sustainable development goals, making it an environmentally friendly choice for offshore engineering projects.

5456 5454 5754 Marine Grade Aluminum Bar Type

5456 5454 5754 Marine Grade Aluminum Round Bars: These are cylindrical bars made from marine grade aluminum (specifically alloys 5456, 5454 and 5754). They may be used in a variety of marine applications where corrosion resistance and strength are critical.

5456 5454 5754 Marine Grade Aluminum Square Bars: Similar to round bars, but with a square cross-section. They provide versatility in applications where a square shape is preferred or required.

Marine Grade 5454 5456 5754 Aluminum Hexagonal Bar: These bars have a hexagonal (hexagonal) cross-section. Like round and square bars, they are made from marine grade aluminum alloys 5454, 5456 and 5754. The hexagonal shape offers advantages in certain applications where a secure fit or specific mechanical properties are required.

5456 5454 5754 Marine Grade Aluminum Bar is specifically designed to withstand the harsh conditions of the marine environment, making it ideal for use in applications such as marine structures, ships, shipbuilding and offshore platforms.

Mechanical properties of marine 5454 5456 5754 aluminum Bar

| Alloy Temper | Inscribed circle diameter/mm | Tensile strength/(N/mm2 ) | Specified non-proportional tensile strength/(N/mm2 ) | Elongation after break/% | |

| A | A 50 mm | ||||

| not less than | |||||

| 5456 o | ≤12.50 | 285-365 | 130 | - | 14 |

| >12.50-150.00 | 285-365 | 130 | 12 | - | |

| 5456 H112 | ≤12.50 | 300 | 130 | - | 12 |

| >12.50-150.00 | 300 | 130 | 10 | - | |

| 5454 o | ≤12.50 | 200-275 | 85 | - | 16 |

| >12.50-200.00 | 200-275 | 85 | 18 | - | |

| 5454 H112 | ≤12.50 | 180 | 80 | - | 12 |

| >12.50-150.00 | 180 | 80 | 14 | - | |

| >150.00-250.0 | 180 | 70 | 13 | - | |

| 5754 o | ≤ 150.00 | 180-250 | 8 0 | 1 7 | 1 5 |

| 5754 H112 | ≤1 50.00 | 180 | 80 | 1 4 | 12 |

| >1 50 .0 0 - 20 0.00 | 180 | 7 0 | 1 3 | - | |

Chemical composition of marine grade aluminum 5456 5454 5754 bars

| Param | 5456 | 5454 | 5754 |

| Si | 0.25 | 0.25 | 0.40 |

| Fe | 0.40 | 0.40 | 0.40 |

| Cu | 0.10 | 0.10 | 0.10 |

| Mn | 0.5-1.0 | 0.5-1.0 | 0.50 |

| Mg | 4.7-5.5 | 2.4-3.0 | 2.6-3.6 |

| Cr | 0.05-0.20 | 0.05-0.20 | 0.30 |

| Zn | 0.25 | 0.25 | 0.20 |

| Ti | 0.20 | 0.20 | 0.15 |

| Al | REM | REM | REM |

5456 5454 5754 Marine Grade Aluminum Bar Applications

The versatility of 5456, 5454 and 5754 aluminum rods makes them suitable for a wide range of marine engineering applications. From the construction of ship hulls and superstructures to offshore platforms and desalination plants, these alloys play a key role in ensuring the durability and performance of offshore infrastructure. Additionally, their compatibility with a variety of manufacturing technologies allows the creation of customized components suited to specific project requirements, further enhancing their utility in marine engineering.

5456, 5454 and 5754 marine grade aluminum rods represent marine materials whose combination of strength, corrosion resistance and formability make them indispensable in the construction of offshore structures where reliability and durability are critical.

Recommended for you

-

The quality of 5754, 5456, and 5454 marine-grade aluminum round bars fully meets the ship classification standards worldwide: CCS, DNV, NK, ABS, BV, LR, KR.

-

As outstanding representatives of the Al-Mg series alloys, 5456, 5454, and 5754 marine-grade aluminum square bars each have unique performance advantages and application scenarios.

-

Haomei Aluminum is one of the leading 5454, 5456, 5754 aluminum hexagonal bar manufacturers in China, focusing on the research and development and production of high-quality products.

Other content readers are interested in

-

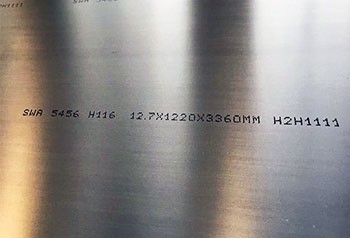

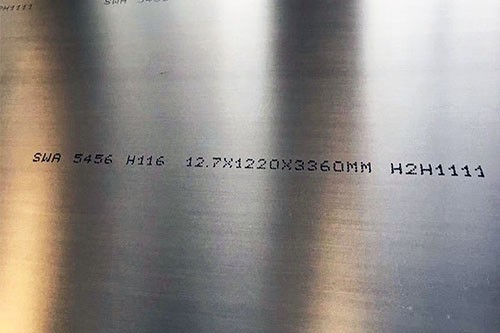

5456 Marine Grade Aluminum Plate Sheet

5456 marine grade aluminum plate is an economical choice for ship construction. Can be used on baseboards, decks and other upper fittings.

-

5754 Marine Grade Aluminum Plate Sheet

5754 marine grade aluminum plate is an aluminum alloy designed specifically for marine applications with excellent corrosion resistance and high strength.

-

5456-H111 aluminum alloy is commonly used in the marine and shipbuilding industries, particularly in environments that require resistance to seawater corrosion.

-

5456-H112 aluminum alloy is a cold-processed and heat-treated aluminum alloy, primarily used in fields that require high corrosion resistance and moderate strength, such as the marine and shipbuilding industries.

-

5456 aluminum alloy is a high-strength aluminum alloy widely used in marine, shipbuilding, offshore engineering, and other corrosion-resistant structural components.

-

5456 H32 aluminum alloy is widely used in the marine and shipbuilding industries. It has good corrosion resistance and is suitable for anti-corrosion structural components in seawater environments.

-

5456 H321 aluminum alloy is a high-strength aluminum alloy primarily used in the marine and shipbuilding industries, especially for corrosion-resistant structures in seawater environments.

-

5456 O aluminum alloy is a state of the 5456 series, referring to the aluminum alloy that has been fully annealed (O state).

-

5754 aluminum sheet is a non-heat-treatable alloy in the 5xxx series, with magnesium as its main alloying element. It is well-known for its excellent corrosion resistance, high strength, and good weldability, making it suitable for a wide range of industrial applications.

-

AW 5754 H111 refers to a specific aluminum-magnesium alloy in the 5000 series, known for its excellent corrosion resistance, medium strength, and good weldability.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

6061 marine aluminum has good corrosion resistance, high strength, good machinability and welding performance, and is suitable for marine structural parts.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

-

5454 aluminum alloy not only possesses excellent corrosion resistance, but its unique high-temperature stress resistance makes it irreplaceable in welded structures for ship fuel tanks and high-temperature environments.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

More content of interest to readers

5456 Aluminum Properties 5049-H24 Aluminum vs. 5754-H24 Aluminum 5754-H14 Aluminum vs. 5754-H22 Aluminum 5754-H22 Aluminum vs. 5754-H32 Aluminum 5754-H28 Aluminum vs. 5754-O Aluminum 5383-O Aluminum vs. 5456-O Aluminum 5383-H32 Aluminum vs. 5456-H32 Aluminum 5383-H111 Aluminum vs. 5456-H111 Aluminum 5383 Aluminum vs. 5456 Aluminum 5383-H112 Aluminum vs. 5456-H112 Aluminum 5456-H116 Aluminum vs. 5456-H32 Aluminum 5086 Aluminum vs. 5456 Aluminum 5456-H112 Aluminum vs. 5456-H116 Aluminum 5456-H111 Aluminum vs. 5456-H116 Aluminum The application of 5456 aluminum plate in shipbuilding Marine grade aluminum 5052 5454 plate for shipbuilding

You might be interested in: Marine Aluminum 5754 Marine Aluminum 5456 Marine Aluminum 5454