5456 H111 Aluminum

5456 H111 aluminum is a high-strength aluminum-magnesium alloy that belongs to the 5000 series (Al-Mg series) wrought aluminum alloys. It is a non-heat-treatable alloy, primarily strengthened through solid solution and cold working processes.

The "H111" temper designation indicates that the material has undergone partial annealing and slight cold working, resulting in specific mechanical properties that balance strength and formability.

This alloy features high strength, excellent corrosion resistance (especially in marine environments), and good weldability, making it a preferred choice for demanding structural applications.

To achieve this temper, 5456 aluminum is strain hardened to a strength level below the maximum limit of H11 (1/8 hard). Compared to other tempers of 5456 aluminum, it has the lowest ductility.

5456 H111 aluminum is specifically designed for high-demand applications such as pressure vessels. Strengthened primarily by magnesium, this alloy offers outstanding comprehensive properties including corrosion resistance, weldability, and lightweight characteristics.

5456 H111 Aluminum Features

- High strength

- Excellent corrosion resistance

- Superior weldability

- Good formability

- Good strength-to-weight ratio

5456 H111 Aluminum Product Forms and Specifications

5456 H111 Aluminum Product Forms

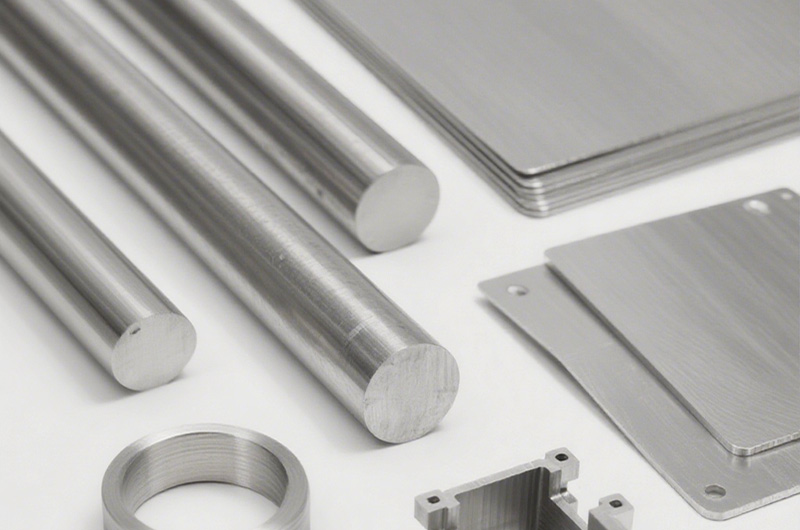

5456 H111 aluminum is available in various product forms to meet different application needs. The most common forms include:

- 5456 H111 Aluminum Plates and Sheets: These are the primary product forms of 5456 H111 aluminum. Sheet thickness is typically less than 6 mm, while plates are thicker. They are widely used in a variety of applications from ship hull outer plates to structural components.

- 5456 H111 Aluminum Extruded Profiles: This alloy can be extruded into various shapes, including channels, angles, tubes, and other custom profiles. These profiles are used for structural supports, frames, and other applications requiring specific cross-sectional shapes.

- 5456 H111 Aluminum Bars and Rods: Solid bars and rods of 5456 H111 aluminum are used in applications requiring machined components or structural supports.

- 5456 H111 Aluminum Forgings: Although not as common as other forms, 5456 can be forged into specific shapes to meet high-stress applications that require enhanced mechanical performance.

- 5456 H111 Aluminum Welding Wire: Although not as commonly used as other Al-Mg alloys such as 5356, 5456 can be used as a filler material for welding specific aluminum alloys.

5456 H111 Aluminum Standards and Specifications

5456 H111 aluminum products comply with multiple international standards. The most important standards include:

- ASTM B209: This is the main standard specification in the U.S. for aluminum and aluminum alloy sheets and plates. It covers the requirements for flat-rolled products of various alloys and tempers, including 5456 H111.

- BS EN 573: This European standard specifies the chemical composition and form of aluminum and aluminum alloys.

- BS EN 485: This European standard defines the mechanical properties for wrought aluminum and aluminum alloy sheets, strips, and plates for general engineering purposes.

- ASTM B928: This standard specifically covers 5456 H116 and H111 aluminum alloy plates used in marine applications.

5456 H111 Aluminum Common Dimensions

The dimensions of 5456 H111 aluminum products vary depending on the product form and manufacturer. Typical dimensions include:

- 5456 H111 Aluminum Plates and Sheets: Thickness ranges from 1.5 mm to 120 mm, width from 1000 mm to 3100 mm, and length from 1000 mm to 13000 mm. For marine applications, commonly used thicknesses range from 4 mm to 12 mm, with widths up to 2500 mm and lengths up to 12000 mm.

- 5456 H111 Aluminum Extruded Profiles: Dimensions vary depending on the specific profile required. For structural shapes such as channels and angles, typical dimensions range from 25 mm to 200 mm.

- 5456 H111 Aluminum Bars and Rods: Round bar diameters typically range from 6 mm to 200 mm. Square and rectangular bar sizes vary accordingly.

It is worth noting that many manufacturers offer custom sizes to meet specific project needs, especially for large-scale marine applications.

5456 H111 Aluminum Material Properties and Characteristics

5456 H111 Aluminum Corrosion Resistance

One of the most notable properties of 5456 H111 aluminum is its excellent corrosion resistance, particularly in marine environments:

- Saltwater resistance: Exceptional resistance to saltwater corrosion due to the high magnesium content.

- Pitting corrosion resistance: Good resistance to pitting corrosion in chloride-rich environments.

- Stress corrosion cracking resistance: Moderate resistance to stress corrosion cracking (SCC) in marine environments.

- Surface protection: Often subjected to additional surface treatments for enhanced protection in severe environments.

5456 H111 Aluminum Chemical Composition

The alloy’s composition (by weight percentage) typically falls within the following ranges:

- Aluminum (Al): 92.0 – 94.8%

- Magnesium (Mg): 4.7 – 5.5%

- Manganese (Mn): 0.5 – 1.0%

- Iron (Fe): Up to 0.4%

- Silicon (Si): Up to 0.25%

- Chromium (Cr): 0.05 – 0.2%

- Zinc (Zn): Up to 0.25%

- Titanium (Ti): Up to 0.2%

- Copper (Cu): Up to 0.1%

- Residuals: Up to 0.15%

The relatively high magnesium content is key to its strength and workability while also contributing to its excellent resistance to corrosion.

5456 H111 Aluminum Mechanical Properties

The mechanical properties of 5456 H111 aluminum are significant for its structural applications:

- Tensile Strength250-352 MPa (36, 000-51, 000 psi)

- Yield Strength~255 MPa (37, 000 psi)

- Elongation6-10%

- Hardness~90 Brinell

5456 H111 Aluminum Thermal and Electrical Properties

- Thermal conductivity: ~116 W/m·K (805 BTU·in/ft²·hr·°F)

- Thermal expansion coefficient: ~23.9 x 10⁻⁶/°C (20-100°C)

- Electrical conductivity: ~29% IACS

- Melting point: ~568°C (1054°F)

5456 H111 Aluminum Welding Characteristics

Weldability is another strong suit of 5456 H111 aluminum:

- General weldability: Excellent weldability without significant loss of strength in the heat-affected zone.

- Welding processes: Suitable for TIG, MIG, and arc welding.

- Filler materials: Typically uses 5000-series filler materials like 5183 or 5356.

- Weld strength: Welds can achieve strengths close to those of the base metal.

5456 H111 Aluminum Processing and Fabrication Characteristics

5456 H111 aluminum alloy has good processing and manufacturing characteristics, but there are also some considerations:

- Machinability: This alloy exhibits moderate to good machinability, especially in the annealed condition. However, in the H111 temper, due to its work-hardening properties, machining can be somewhat challenging, which may lead to increased tool wear.

- Cold Working: 5456 H111 aluminum alloy can be cold worked to increase its strength, but this reduces its ductility. Cold working processes include bending, forming, and stamping, but care must be taken to avoid excessive stress concentration.

- Hot Working: The alloy can also be hot worked, though this is less common than cold working. Hot working is usually conducted below 300°C to avoid degrading the material's properties.

- Formability: 5456 H111 aluminum alloy has good formability and can be shaped into various forms based on different application requirements. However, its formability is slightly lower than that of lower-strength aluminum alloys.

- Surface Treatment: This alloy responds well to a variety of surface treatments, including anodizing, painting, and polishing. These treatments can enhance its appearance and provide additional corrosion protection.

Specific Applications of 5456 H111 Aluminum in Marine Environments

Shipbuilding and Marine Construction

Due to its excellent saltwater corrosion resistance and high strength-to-weight ratio, 5456 H111 aluminum is widely used in various aspects of shipbuilding and marine construction.

- Hull Structures: This alloy can resist seawater corrosion, making it an ideal choice for hull cladding and structural components.

- Deck Systems: Used for deck plates and support structures that must endure constant exposure to seawater, weathering, and heavy loads.

- Superstructures: In large vessels such as destroyers and frigates, 5456 H111 aluminum is used in superstructures above the main deck.

- Internal Structural Components: Bulkheads, frames, and other internal structural elements benefit from the alloy’s corrosion resistance and workability.

Offshore Structures and Marine Engineering

Beyond shipbuilding, 5456 H111 aluminum is also widely used in various offshore engineering sectors:

- Offshore Platforms: Used in the construction of offshore drilling platforms and support structures where resistance to saltwater and atmospheric corrosion is crucial.

- Marine Renewable Energy Installations: Used in the construction of offshore wind turbines and tidal energy systems.

- Port Infrastructure: Used in building docks, piers, and other harbor facilities that are frequently exposed to seawater and the marine environment.

- Subsea Equipment: Components of underwater devices, including housings, frames, and structural supports.

Naval and Military Applications

The unique properties of 5456 H111 aluminum make it especially suitable for naval and military applications:

- Military Vessels: Used in the construction of patrol boats, mine sweepers, and other naval vessels where weight reduction and corrosion resistance are critical.

- Naval Superstructures: Extensively used in the superstructures of U.S. Navy destroyers and other large surface ships.

- Lightweight Armor: Used in lightweight armor plates due to its high strength and low weight.

- Marine Transport Equipment: Used in the construction of military landing crafts, amphibious vehicles, and other marine transport systems.

What Other Fields Use 5456 H111 Aluminum?

Aerospace Applications

- Aircraft Structures

- Fuel Tanks and Systems

- Interior Components

- Helicopter Parts

- Automotive Applications

Automotive Structures

- Commercial Vehicles

- Rail Transit

- Trailers and Containers

Pressure Vessels

- High-Pressure Vessels

- Chemical Storage Tanks

- LNG and Cryogenic Storage

- Fire Suppression Systems

Architectural Applications

- Structural Components

- Building Cladding

- Bridges and Walkways

- Window and Door Frames

5456 H111 Aluminum Comparison with Other Aluminum Alloys

5456 H111 Aluminum Comparison with 5083 Aluminum

| Property | 5456 H111 | 5083 |

| Magnesium Content | 4.7-5.5% | 4.0-4.9% |

| Tensile Strength | 352 MPa | 317 MPa |

| Corrosion Resistance | Good | Better |

| Weldability | Excellent | Excellent |

| Machinability | Fair to good | Better |

| Typical Applications | Structural applications requiring high strength | Applications requiring maximum corrosion resistance |

5456 H111 Aluminum Comparison with 5086 Aluminum

| Property | 5456 H111 | 5086 |

| Magnesium Content | 4.7-5.5% | 3.5-4.5% |

| Tensile Strength | Higher | Lower |

| Formability | Good | Better |

| Corrosion Resistance | Good | Good |

| Typical Applications | High-strength structural applications | General marine and structural applications |

Haomei 5456 H111 Aluminum Product Forms

| Category | Product Form |

| Bar Products | 5456 H111 Flat Bar |

| 5456 H111 Half Round | |

| 5456 H111 Hexagon Bar | |

| 5456 H111 Octagonal Bar | |

| 5456 H111 Round Bar | |

| 5456 H111 Square Bar | |

| Structurals | 5456 H111 Shapes (Extruded) |

| Structurals | 5456 H111 Angle |

| 5456 H111 Angle (Unequal Leg) | |

| 5456 H111 Beams (H) | |

| 5456 H111 Beams (I) | |

| 5456 H111 Channel | |

| 5456 H111 Tees | |

| 5456 H111 Zees | |

| Tubular Products | 5456 H111 Pipe (Seamless) |

| 5456 H111 Tube (Rectangular) | |

| 5456 H111 Tube (Square) |

Haomei 5456 H111 Aluminum Bar Products

| Product Form | Description |

| 5456 H111 Aluminum Flat Bar | 5456 H111 flat bars are widely used in the frame and support structures of shipbuilding, offshore platforms, and underwater equipment. Its excellent corrosion resistance makes it durable in marine environments, suitable for making hull edges, beams, and other load-bearing components. |

| 5456 H111 Aluminum Half Round | 5456 H111 half-round bars are commonly used in collision protection devices or guiding structures on ships and offshore platforms. They can serve as auxiliary support parts for the ship's hull, ensuring that the structure has the necessary elasticity and corrosion resistance in marine environments. |

| 5456 H111 Aluminum Hexagon Bar | 5456 H111 hexagonal bars are commonly used as fasteners, connectors, and other structural components in the marine industry, particularly in shipbuilding and offshore platform structures. Its excellent corrosion resistance and strength make it a common choice in seawater and other corrosive environments. |

| 5456 H111 Aluminum Octagonal Bar | 5456 H111 octagonal bars are used as polygonal brackets or specialized components in marine equipment, particularly for installations on offshore platforms or underwater facilities. Their shape is conducive to the fitting and stability of special structures, meeting the needs of complex marine engineering projects. |

| 5456 H111 Aluminum Round Bar | 5456 H111 round bars are commonly used for pipeline supports, fasteners, and other structural components on offshore platforms. Its excellent machinability and good resistance to seawater corrosion make it an indispensable material for ships and offshore platforms. |

| 5456 H111 Aluminum Square Bar | 5456 H111 square bars are widely used in frame structures and support components in the marine industry. They can be used for hull reinforcement, support beams on offshore platforms, and various corrosion-resistant marine engineering projects. |

Haomei 5456 H111 Aluminum Structurals (Extruded)

| Product Form | Description |

| 5456 H111 Shapes (Extruded) | 5456 H111 extruded shapes are widely used in structural components for ships and offshore platforms. Due to its lower strength and excellent formability, it is ideal for manufacturing complex structural shapes such as frames, beams, and support structures, capable of withstanding high corrosion pressures in marine environments. |

Haomei 5456 H111 Aluminum Structurals

| Product Form | Description |

| 5456 H111 Angle Aluminum | 5456 H111 angle bars are commonly used in the frame and support structures of ships and offshore platforms. Due to their excellent corrosion resistance and adequate strength, they are suitable for horizontal beams and vertical supports, ensuring the stability of structures in harsh marine environments. |

| 5456 H111 Angle (Unequal Leg) Aluminum | 5456 H111 unequal leg angle bars are widely used in marine engineering, especially in complex structures requiring different size supports, such as the frame systems of ships and offshore platforms. They provide strong structural stability and can effectively withstand mechanical loads in offshore environments. |

| 5456 H111 Beams (H) Aluminum | 5456 H111 H-beams are commonly used in the structures of offshore platforms and ships, especially in areas where large pressure and weight need to be supported. Their excellent corrosion resistance and high strength make them suitable for long-term use in marine environments. |

| 5456 H111 Beams (I) Aluminum | 5456 H111 I-beams are commonly used in support structures for offshore platforms, ships, and other marine facilities. This structural form effectively distributes loads and is suitable for use in harsh marine environments, with corrosion resistance and moderate strength. |

| 5456 H111 Channel Aluminum | 5456 H111 channel bars are used as support structures and framing materials in ships and offshore platforms. Due to their excellent weldability and strong corrosion resistance, they perform excellently in long-term exposure to seawater. |

| 5456 H111 Tees Aluminum | 5456 H111 T-bars are commonly used as crossbeams and support structures in marine and shipbuilding industries. Due to their excellent resistance to seawater corrosion, T-bars have a long service life in marine environments and are suitable for carrying important structural loads. |

| 5456 H111 Zees Aluminum | 5456 H111 Z-bars are typically used in reinforced frameworks and support structures for ships and offshore platforms. Their shape and corrosion resistance make them particularly suitable for load-bearing and reinforcement applications in marine environments. |

Haomei 5456 H111 Aluminum Tubular Products

| Product Form | Description |

| 5456 H111 Aluminum Pipe (Seamless) | 5456 H111 seamless pipes are commonly used in marine engineering as pipelines and conveyance systems, particularly for transporting seawater or other liquids in ships and offshore platforms. Its corrosion resistance makes it highly durable in seawater environments. |

| 5456 H111 Aluminum Tube (Rectangular) | 5456 H111 rectangular tubes are typically used in the frame structures and support systems of ships and offshore platforms. Its excellent corrosion resistance and formability make it widely used in marine structures, especially in areas that require high corrosion resistance. |

| 5456 H111 Aluminum Tube (Square) | 5456 H111 square tubes are used in marine applications such as shipbuilding, platforms, and underwater equipment frames. They not only provide high-strength support but also effectively resist seawater corrosion, making them ideal for long-term exposure in marine environments. |

Comparison with Other 5456 Aluminum Alloy States

5456 aluminum alloy is a high-strength alloy commonly used in marine and shipbuilding industries, offering excellent corrosion resistance, particularly in seawater environments. It exhibits different mechanical properties and applications depending on the heat treatment state.

5456 aluminum alloy has different performance characteristics and applications in various heat treatment states. States like H111, H112, and H116 are suitable for ships, marine engineering, and corrosion-resistant structural components, while states like H32, H321, and O are better for applications requiring further processing or higher strength.

- H111 State: Suitable for applications that do not require exceptionally high strength, such as ship hulls, marine platform structures, etc. It offers good formability and weldability, and strong corrosion resistance, but has lower strength.

- H112 State: Has slightly higher strength, making it suitable for applications that require a certain level of strength.

- H116 State: A high-strength state with excellent corrosion resistance, commonly used for structural components that require high resistance to corrosion, such as highly corrosion-resistant hull parts and marine platforms.

Advantages of 5456 H111 Aluminum

- Corrosion Resistance: Excellent corrosion resistance in seawater environments, making it an ideal choice for marine engineering and shipbuilding structures.

- Good Weldability: In the H111 state, 5456 aluminum alloy has excellent weldability, allowing for welding in complex structures, suitable for the needs of environments like offshore platforms.

- Formability: It has good ductility and formability, making it suitable for applications that require complex shapes and processing.

5456-H111 aluminum alloy is a material highly suited for marine, shipbuilding, and underwater environments. Its excellent corrosion resistance, moderate strength, and superior weldability make it widely used in these fields. Although its strength is lower than that of other heat-treated states of 5456 aluminum alloy, it still meets the needs of most marine structural components, especially in applications where high strength is not particularly required.

Recommended for you

-

5456 marine grade aluminum plate is an economical choice for ship construction. Can be used on baseboards, decks and other upper fittings.

-

5456-H112 aluminum alloy is a cold-processed and heat-treated aluminum alloy, primarily used in fields that require high corrosion resistance and moderate strength, such as the marine and shipbuilding industries.

-

5456 aluminum alloy is a high-strength aluminum alloy widely used in marine, shipbuilding, offshore engineering, and other corrosion-resistant structural components.

-

5456 H32 aluminum alloy is widely used in the marine and shipbuilding industries. It has good corrosion resistance and is suitable for anti-corrosion structural components in seawater environments.

-

5456 H321 aluminum alloy is a high-strength aluminum alloy primarily used in the marine and shipbuilding industries, especially for corrosion-resistant structures in seawater environments.

-

5456 O aluminum alloy is a state of the 5456 series, referring to the aluminum alloy that has been fully annealed (O state).

Other content readers are interested in

-

5456 5454 5754 Marine Grade Aluminum Bar

5456 5454 5754 Marine Grade Aluminum Bar has certification from CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and its quality fully complies with world marine grade standards.

-

Marine Grade Aluminum Round Bar 5754 5454 5456

The quality of 5754, 5456, and 5454 marine-grade aluminum round bars fully meets the ship classification standards worldwide: CCS, DNV, NK, ABS, BV, LR, KR.

-

5456 5454 5754 Marine Grade Aluminum Square Bars

As outstanding representatives of the Al-Mg series alloys, 5456, 5454, and 5754 marine-grade aluminum square bars each have unique performance advantages and application scenarios.

-

5454 5456 5754 Marine Grade Hexagonal Aluminum Bar

Haomei Aluminum is one of the leading 5454, 5456, 5754 aluminum hexagonal bar manufacturers in China, focusing on the research and development and production of high-quality products.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

More content of interest to readers

5456 Aluminum Properties 5383-O Aluminum vs. 5456-O Aluminum 5383-H32 Aluminum vs. 5456-H32 Aluminum 5383-H111 Aluminum vs. 5456-H111 Aluminum 5383 Aluminum vs. 5456 Aluminum 5383-H112 Aluminum vs. 5456-H112 Aluminum 5456-H116 Aluminum vs. 5456-H32 Aluminum 5086 Aluminum vs. 5456 Aluminum 5456-H112 Aluminum vs. 5456-H116 Aluminum 5456-H111 Aluminum vs. 5456-H116 Aluminum The application of 5456 aluminum plate in shipbuilding

You might be interested in: Marine Aluminum 5456 5 Series Marine Aluminum