5456 5454 5754 Marine Grade Aluminum Square Bars

As outstanding representatives of the Al-Mg series alloys, 5456, 5454, and 5754 marine-grade aluminum square bars each have unique performance advantages and application scenarios:

- The 5456 marine-grade aluminum square bar, with its high strength, excellent corrosion resistance, and good low-temperature performance, is an ideal choice for marine environments and extreme conditions. It performs well in shipbuilding, marine engineering, and low-temperature equipment, making it a high-performance and reliable engineering material.

- The 5454 marine-grade aluminum square bar offers a good balance of strength, corrosion resistance, and workability, while also maintaining a high cost-performance ratio. It is widely used in automobile manufacturing, architectural decoration, chemical equipment, and other fields, making it a versatile and economical engineering material.

- The 5754 marine-grade aluminum square bar, known for its excellent corrosion resistance, good formability, and weldability, is a preferred material in many industries. It performs well in the automotive industry, construction sector, rail transit, and more, making it a material with excellent overall performance and broad applications.

Material Characteristics and Advantages of 5456, 5454, and 5754 Marine Aluminum Square Bars

5456 Marine-Grade Aluminum Square Bar

Belonging to the Al-Mg series alloy, it is an improved alloy developed from 5083 aluminum with several remarkable advantages.

- Excellent welding performance: 5456 aluminum square bar can be connected by hydrogen atomic welding, spot welding, gas welding, TIG welding, and other methods. This property allows for easy structural connections in shipbuilding and marine engineering while maintaining high strength and corrosion resistance.

- Outstanding processability: This alloy exhibits high plasticity in the annealed state and moderate plasticity during semi-cold work hardening, making it suitable for various cold and hot processing operations. It can be easily processed into various shapes and structures to meet diverse project requirements.

- Good low-temperature performance: The 5456 marine-grade aluminum square bar maintains excellent mechanical properties in low-temperature environments, unlike many steels that become brittle at low temperatures. This makes it especially suitable for marine equipment used in cold sea areas or low-temperature conditions.

- High recyclability and environmental friendliness: As a recyclable material, the 5456 aluminum square bar can be fully reused after being scrapped, reducing resource waste and environmental impact. This aligns with the modern shipbuilding industry’s goals for sustainable development.

5454 Marine-Grade Aluminum Square Bar

Also part of the Al-Mg alloy family, it differs slightly in chemical composition from 5456, with a magnesium content of 2.6–3.6%.

- Excellent resistance to seawater and organic acid corrosion: The 5454 aluminum alloy has outstanding resistance to seawater and certain organic acids, making it ideal for marine and chemical applications where it resists various corrosive substances.

- Good formability and weldability: The 5454 aluminum square bar has excellent cold workability and is suitable for stamping, bending, drawing, and other forming processes. It is also easy to weld using TIG/MIG welding, resistance welding, and other methods, with strong weld joints. This gives it a clear advantage in manufacturing complex structures.

- Moderate strength and good toughness balance: The strength of 5454 aluminum alloy is about 20% higher than that of 5052. Its characteristics are similar to 5154 but with better corrosion resistance in harsh environments. This balance makes it suitable for a wide range of marine applications.

- Good surface treatment properties: The surface of 5454 aluminum square bar can undergo various treatments, such as anodizing, spraying, electrophoretic coating, etc., to enhance appearance and corrosion resistance. This improves its protective capability in marine environments while meeting different project aesthetic requirements.

- Excellent cost-performance ratio: Compared with some high-strength but expensive alloys, the 5454 aluminum square bar offers an excellent balance between performance and reasonable pricing, making it a cost-effective choice for many marine applications.

5754 Marine-Grade Aluminum Square Bar

Also an important member of the Al-Mg alloy family, it contains 2.6–3.6% magnesium and 0.5–0.8% manganese.

- Outstanding corrosion resistance: The 5754 aluminum bar contains magnesium and manganese, providing excellent corrosion resistance, especially suitable for humid and corrosive environments. Its surface can form a dense oxide film (Al₂O₃), further enhancing its corrosion resistance. This makes the 5754 aluminum square bar an ideal material for marine environments.

- Good forming and processing performance: The 5754 aluminum alloy has excellent cold and hot processing performance, meeting various complex design needs. Whether for enclosures, structural components, or high-strength parts, it performs reliably.

- Lightweight with moderate strength: The density of 5754 aluminum square bar is about 2.66 g/cm³, making it lightweight and suitable for applications requiring weight reduction. Its strength is higher than pure aluminum and meets medium-strength needs while maintaining good workability. This lightweight characteristic is especially important in ship design to reduce overall weight and improve fuel efficiency.

- Excellent weldability: The 5754 aluminum square bar is easy to weld and suitable for various welding processes, such as TIG welding and resistance welding. This makes structural connections in shipbuilding and marine engineering convenient while maintaining structural integrity.

- Wide applicability: The 5754 aluminum alloy is favored for its good formability and weldability, making it ideal for manufacturing vehicle body structures, fuel tanks, hulls, etc. Its wide applicability makes it a preferred material across various industries.

Performance Comparison of 5456, 5454, and 5754 Alloys

To compare the performance differences among these three alloys more intuitively, here is a comparison of their main characteristics:

| Characteristic | 5456 Marine-Grade Aluminum Square Bar | 5454 Marine-Grade Aluminum Square Bar | 5754 Marine-Grade Aluminum Square Bar |

| Main alloying elements | Mg (4.7–5.7%), Mn (0.20–0.6%), Ti (≤0.15%) | Mg (2.6–3.6%), Mn (0.5%) | Mg (2.6–3.6%), Mn (0.5–0.8%) |

| Strength | High strength, comparable to 5A03 | Medium strength, about 20% higher than 5052 | Medium strength, higher than pure aluminum |

| Corrosion resistance | Excellent, especially stress corrosion resistance | Excellent, good resistance to seawater and organic acids | Outstanding, performs well in humid and corrosive environments |

| Weldability | Good, supports multiple welding methods | Excellent, suitable for various welding processes | Excellent, suitable for various welding processes |

| Processability | High plasticity in annealed state, moderate during semi-cold work hardening | Good cold workability, suitable for various forming processes | Good cold and hot processing performance |

| Low-temperature performance | Excellent, maintains good toughness at low temperatures | Good | Good |

| Typical applications | Ship decks, hull structures, high-strength welded structures | Ship interior structures, marine facility pipelines, automobile wheels | Hull structures, decks, bulkheads, pressure vessels |

Mechanical properties of 5456 5454 5754 aluminium square bar

| Alloy | Temper | Diameter/mm | Tensile strength RmMPa | Extension strength RP0.2/Mpa | Elongation% | ||||

| A50mm | A | ||||||||

| NO LESS THAN | |||||||||

| 5456 | O, H112 | ALL | 300 | 130 | 12 | 10 | |||

| 5454 | O, H112 | ALL | 200 | 85 | 16 | 14 | |||

| 5754 | H112 | ALL | 180 | 80 | 14 | 12 | |||

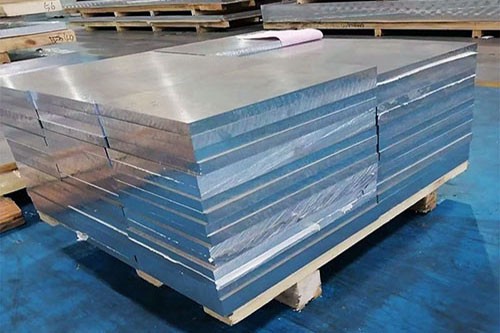

Common Specifications of 5456, 5454, 5754 Marine-Grade Aluminum Square Bars

| Alloy Type | Common Tempers | Side Length Range | Common Length Range |

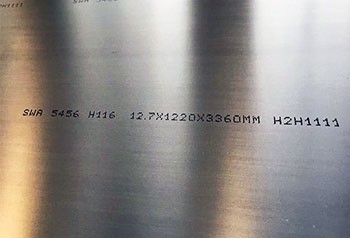

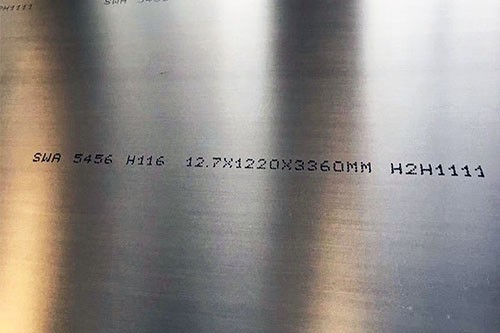

| 5456 | H116 (Marine Grade), H321 | 10mm × 10mm – 200mm × 200mm | 2m, 3m, 6m (standard); customizable up to 12m or more |

| 5454 | H32 | 10mm × 10mm – 150mm × 150mm | 2m, 3m, 6m (standard); customizable up to 12m or more |

| 5754 | H111, H321, O (Annealed) | 10mm × 10mm – 200mm × 200mm | 2m, 3m, 6m (standard); customizable up to 12m or more |

Temper Characteristics:

- H116 (5456): Specifically designed for marine environments, excellent resistance to seawater corrosion, suitable for hulls and offshore structures.

- H32/H321: Strain-hardened and partially annealed, balancing strength and workability, ideal for welded structures.

- O (Annealed): Soft texture, easy to form, used for non-structural components with complex bending requirements.

Dimensional Tolerances:

- Side length tolerance: For standard sizes (10–100mm), typically ±0.1mm to ±0.5mm; for precision parts, can be controlled within ±0.05mm.

- Length tolerance: Standard length ±15mm; customized lengths can be adjusted as needed.

Industry Standards:

Compliant with ASTM B221 (extruded aluminum bar dimensional tolerances), EN 573-3 (alloy composition standard), certified by classification societies such as DNV GL/ABS for marine applications.

Chemical composition of marine grade aluminum 5456 5454 5754 square bars

| 5456 | 5454 | 5754 | |

| Si | 0.25 | 0.25 | 0.40 |

| Fe | 0.40 | 0.40 | 0.40 |

| Cu | 0.10 | 0.10 | 0.10 |

| Mn | 0.5-1.0 | 0.5-1.0 | 0.50 |

| Mg | 4.7-5.5 | 2.4-3.0 | 2.6-3.6 |

| Cr | 0.05-0.20 | 0.05-0.20 | 0.30 |

| Zn | 0.25 | 0.25 | 0.20 |

| Ti | 0.20 | 0.20 | 0.15 |

| Al | REM | REM | REM |

Selection Recommendations and Application Prospects of 5456, 5454, 5754 Marine-Grade Aluminum Square Bars

When selecting 5456, 5454, or 5754 marine-grade aluminum square bars, comprehensive consideration should be given to specific application requirements, environmental conditions, and cost constraints:

- Select based on application environment: For marine or highly corrosive environments, prioritize 5456 or 5754 alloys; for general industrial environments, 5454 may be a more economical choice.

- Select based on performance requirements: For applications requiring high strength and fatigue resistance, consider 5456 alloy; for applications needing excellent formability and weldability, 5454 or 5754 alloys are more suitable; for balanced overall performance, 5754 alloy is a good option.

- Select based on processing methods: For applications involving complex machining, choose 5454 or 5754 alloys due to better machinability; for simple structures or mainly welded joints, all three alloys can be considered.

- Select based on budget: Within performance constraints, choose based on budget. Generally, 5454 alloy offers the best cost-performance ratio, while 5456 alloy may be more expensive due to its high performance.

Applications of 5456, 5454, and 5754 Aluminum Square Bars in Marine Shipbuilding

Applications of 5456 Marine-Grade Aluminum Square Bar in Shipbuilding

Due to its excellent comprehensive properties, 5456 marine-grade aluminum square bar is widely used in shipbuilding, mainly in the following areas:

- Ship bottom and keel structure: With its high strength and superior seawater corrosion resistance, 5456 aluminum bar is commonly used in key structural parts such as the hull bottom and keel. These components are in direct contact with seawater and require excellent corrosion resistance and structural strength.

- Ship deck systems: 5456 aluminum bar is an ideal material for ship decks, especially in areas subjected to high loads and harsh environments. Different tempers of 5456 aluminum plate meet the specific requirements of various deck areas, such as living decks, walking decks, and bridge decks.

- Ship bulkheads and partitions: 5456 aluminum bar is widely used in ship bulkhead and partition structures, providing solid structural support and compartmentalization while reducing the overall weight of the ship.

- Ship superstructures: Thanks to its lightweight and high strength, 5456 aluminum bar is used in ship superstructures, such as wheelhouses and deckhouses, helping lower the center of gravity and improve navigational stability.

- Internal ship structures: 5456 aluminum bars are also used for various internal ship structures, such as frames and supports, providing necessary strength and structural integrity.

- Special-purpose vessels: For special-purpose vessels such as high-speed boats, workboats, and yachts, 5456 aluminum bar is favored due to its high strength-to-weight ratio. These vessels demand high performance materials, and 5456 meets these demands perfectly.

Applications of 5454 Marine-Grade Aluminum Square Bar in Shipbuilding

5454 marine-grade aluminum square bar also has its unique applications in shipbuilding, mainly including:

- Internal ship structures: Due to its good strength and corrosion resistance, 5454 aluminum bar is often used in flooring and frame structures inside ships. Although these parts may not directly contact seawater, they still require moisture and corrosion resistance.

- Ship piping systems: 5454 aluminum bar is especially suitable for ship piping systems, particularly those transporting seawater or other corrosive liquids. Its excellent corrosion resistance ensures long-term, stable operation.

- Ship interior finishes and decorations: 5454 aluminum bar can be used for interior decorative parts and structures such as handrails and trim. Its good machinability and surface treatment properties meet various decorative needs.

- Ship refrigeration systems: As 5454 aluminum bar maintains good mechanical properties in low-temperature environments, it is also applied in ship refrigeration and cold storage areas.

- Ship ventilation systems: 5454 aluminum bar is used to manufacture ventilation ducts and structures, offering good corrosion resistance and structural strength.

- Small structural ship parts: 5454 aluminum bar is widely used for various small components in ships, such as brackets, connectors, and fixtures, providing reliable connection and support.

Applications of 5754 Marine-Grade Aluminum Square Bar in Shipbuilding

With excellent overall performance, 5754 marine-grade aluminum square bar plays a vital role in shipbuilding, with applications including:

- Hull structures: 5754 aluminum bar is an ideal material for hull structures, providing necessary strength and rigidity while reducing overall weight. Its excellent corrosion resistance ensures long-term use in marine environments.

- Ship decks: 5754 aluminum bar is used in manufacturing various decks, including main decks, upper decks, and platform decks. Its high strength and good fatigue resistance allow it to bear various loads.

- Ship bulkheads: 5754 aluminum bar is widely used in ship bulkhead structures, offering partitioning and structural support while reducing overall ship weight.

- Ship superstructures: 5754 aluminum bar is important in superstructures such as wheelhouses, deckhouses, and passenger cabins, helping to lower the center of gravity and improve navigational stability.

- Interior decorations: With excellent processing and surface finishing properties, 5754 aluminum bar is used in making various decorative elements such as ceilings, wall panels, and trim.

- Ship fuel and water tanks: Due to its outstanding corrosion and welding properties, 5754 aluminum bar is ideal for manufacturing ship fuel and water tanks and other liquid storage containers. These containers require tight sealing and corrosion resistance, which 5754 provides.

- Special ship structures: For special ship structures such as yacht superstructures or lightweight structures of high-speed boats, 5754 aluminum bar is widely used, offering the necessary strength and lightweight benefits.

Selection Guide for 5456, 5454, and 5754 Alloys in Marine Shipbuilding

When choosing the appropriate marine-grade aluminum square bar, the following factors should be considered:

- Application environment: Choose alloys with appropriate corrosion resistance based on the ship's structural location. For components in direct contact with seawater, prioritize 5456 or 5754 alloys; for internal structures, 5454 is appropriate.

- Structural requirements: Different parts require different levels of strength, stiffness, and fatigue resistance. For high-strength requirements, consider 5456; for moderate-strength applications, 5454 or 5754 are suitable.

- Processing method: Since each alloy has different machinability, select based on the required processing. For complex bending or stamping, choose 5454 or 5754; for simple structures, 5456 may suffice.

- Joining method: Since shipbuilding involves extensive welding, alloys with better weldability should be selected. 5454 and 5754 have slightly better weldability than 5456, making them more suitable for complex welded structures.

- Cost factors: While ensuring performance requirements, cost must be considered. 5454 typically offers a better cost-performance ratio, while 5456 may cost more due to its high performance.

Considerations for Purchasing Marine Aluminum Square Bars

Supplier Selection and Qualification Review

- Supplier Certification: Ensure the supplier holds relevant industry production licenses and quality system certifications (DNV, BV, CCS).

- Industry experience and expertise: Give priority to suppliers with extensive experience in the marine aluminum sector.

- Production capacity and supply stability: Assess the supplier’s production capacity and supply reliability to ensure project requirements are met.

- Technical support and after-sales service: Choose suppliers capable of providing comprehensive technical support and strong after-sales service.

- Compliance and environmental requirements: Ensure that the production process and products comply with relevant environmental regulations and standards.

Product Quality and Technical Requirements

- Dimensional tolerance requirements: Clearly specify the tolerance range for marine aluminum square bars.

- Appearance quality requirements: Define appearance standards, such as being free from cracks, scratches, corrosion, and other defects.

- Mechanical properties: Clearly define tensile strength, yield strength, elongation, and other indicators.

- Chemical composition: Clearly specify the required alloy element content in compliance with standard requirements.

- Material standards and specifications: Require that materials conform to relevant national standards and industry codes.

Contract Signing and Acceptance Management

- Clear contract terms: Clearly define key terms such as specifications, quantity, price, and delivery time.

- Quality documentation: Require provision of material certificates, inspection reports, and classification society certificates.

- Incoming inspection process: Establish a strict process for receiving inspection, including checks on quantity, specifications, appearance, and performance.

- Handling of non-conforming products: Clearly define the handling methods and responsibilities for non-conforming products.

- Technical documentation management: Properly store all technical documents related to the materials.

Transportation and Storage Requirements

- Transport packaging and protection: Use appropriate packaging and protection to prevent damage during transportation.

- Transport environment control: Pay attention to temperature and humidity during transportation to prevent rust or degradation.

- Storage environment requirements: Set up dedicated storage warehouses with good ventilation and elevated ground.

- Inventory management: Conduct regular stocktaking and inspect storage conditions.

- First-in, first-out principle: Follow the FIFO principle to ensure rational material usage.

Other Application Fields of 5456, 5454, 5754 Aluminum Square Bars

Diversified Applications of 5456 Marine-Grade Aluminum Square Bar

In addition to marine shipbuilding, 5456 marine-grade aluminum square bars are widely used in several other industries:

- Marine engineering and offshore facilities: 5456 aluminum bars are widely used in offshore platforms, subsea pipelines, and ocean observation equipment due to their excellent corrosion resistance and high strength. These applications require outstanding structural strength and anti-corrosion properties.

- Construction structures: 5456 aluminum bars play an important role in construction, especially in projects with high requirements for corrosion resistance and lightweight design, such as seaside buildings, long-span structures, and roofing systems. Their lightweight and high strength help reduce structural weight and improve seismic performance.

- Cryogenic equipment and containers: As 5456 aluminum maintains good mechanical properties at low temperatures, it is used in various cryogenic equipment and containers, such as LNG tanks, low-temperature pipelines, and refrigeration units.

- Transportation sector: 5456 aluminum bars can be used in structural components of transportation vehicles such as high-speed trains, subway components, and automotive crash structures. Their lightweight characteristics help improve energy efficiency and operational performance.

- Armor and protective equipment: Thanks to their high strength and impact resistance, 5456 aluminum bars are used in manufacturing armor plates and protective gear such as bulletproof vehicles, blast-proof walls, and safety barriers.

- Pressure vessels and piping systems: 5456 aluminum bars can be used in manufacturing various pressure vessels and piping systems, especially in high-pressure and corrosive environments. Their strength and corrosion resistance ensure safe and reliable operation.

Extensive Applications of 5454 Marine-Grade Aluminum Square Bar

With excellent overall properties, 5454 marine-grade aluminum square bars perform well in various sectors:

- Automotive industry: 5454 aluminum bars are widely used in wheels, body structures, and chassis components. Their strength and corrosion resistance help enhance vehicle safety and lifespan, while lightweight properties help reduce fuel consumption.

- Pressure vessels and storage tanks: 5454 aluminum bars are suitable for air tanks, LPG tanks, and chemical storage tanks. Their strength and corrosion resistance ensure safe and reliable performance.

- Architectural decoration: 5454 aluminum bars are used in architectural decorations such as curtain walls, ceilings, decorative moldings, and door and window frames. Their excellent machinability and surface finish capabilities meet aesthetic demands.

- Rail transit: 5454 aluminum bars are applied in structural and decorative components for trains, such as carriage bodies, interior decor, and handrails. Their lightweight nature improves efficiency and performance.

- Chemical equipment and piping: 5454 aluminum bars exhibit good corrosion resistance to organic acids and chemicals, making them suitable for equipment and pipelines in corrosive environments.

- Food and beverage industry: 5454 aluminum bars are used in food processing equipment, beverage storage tanks, and transport containers. Their corrosion resistance and hygienic properties ensure food safety.

Other Applications of 5754 Marine-Grade Aluminum Square Bar

5754 marine-grade aluminum square bars also exhibit excellent performance across multiple industries:

- Automotive industry: 5754 aluminum bars are used for car body panels, fuel tanks, and chassis components. Their lightweight and corrosion resistance enhance fuel efficiency and lifespan. In particular, their lightweight nature contributes to longer battery range in new energy vehicles.

- Construction industry: 5754 aluminum bars are widely applied in roofing, walls, and curtain walls. Their weather resistance and strength meet structural demands, and diverse surface treatments fulfill aesthetic requirements.

- Chemical equipment: 5754 aluminum bars are used for tanks, pipes, and reactors in chemical plants. Their corrosion resistance allows safe use in harsh chemical environments.

- Rail transit: 5754 aluminum bars are used in train carriages and body structures. Their lightweight design enhances efficiency and loading capacity, while corrosion resistance extends service life.

- Pressure vessels: 5754 aluminum bars are ideal for LPG tanks and compressed air cylinders. Their welding performance and strength meet safety requirements under high pressure and variable conditions.

- Aerospace industry: In aerospace, 5754 aluminum bars are used in non-load-bearing structures and interiors such as cabin trim, flooring, and partitions. Their lightweight helps reduce aircraft weight and improve performance.

- Medical equipment: Thanks to corrosion resistance and biocompatibility, 5754 aluminum bars are used in medical beds, surgical tables, and medical carts. Their lightweight and easy-clean features are ideal in medical environments.

Application Scenario Comparison of 5456, 5454, and 5754 Alloys

To provide a clearer comparison of the application differences among the three alloys, below is a comparison of their use in various fields:

| Application Field | 5456 Marine-Grade Aluminum Square Bar | 5454 Marine-Grade Aluminum Square Bar | 5754 Marine-Grade Aluminum Square Bar |

| Marine Engineering | Offshore platform structures, subsea pipelines, ocean observation equipment | Marine facility piping, seawater treatment equipment | Platform decks, marine instrument housings |

| Construction | Seaside structures, large-span roofs, curtain wall frameworks | Decorative moldings, window and door frames, ceilings | Curtain walls, roof structures, decorative panels |

| Transportation | High-speed train bodies, subway components, automotive crash structures | Car wheels, body structural parts, chassis components | Body panels, fuel tanks, train carriages |

| Energy Equipment | Cryogenic tanks, LNG containers, high-pressure pipelines | Chemical equipment piping, reactors, storage containers | Pressure vessels, LPG tanks, compressed air tanks |

| Industrial Equipment | Armor protection gear, safety barriers, explosion-proof structures | Food processing equipment, beverage tanks, transport containers | Chemical equipment, medical devices, aerospace interior components |

| Daily Use | Premium furniture frames, art piece frames, special decorative parts | High-end kitchenware, furniture trim, decorative structural components | Furniture panels, decorative moldings, premium home goods |

Recommended for you

-

5456 5454 5754 Marine Grade Aluminum Bar has certification from CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and its quality fully complies with world marine grade standards.

-

The quality of 5754, 5456, and 5454 marine-grade aluminum round bars fully meets the ship classification standards worldwide: CCS, DNV, NK, ABS, BV, LR, KR.

-

Haomei Aluminum is one of the leading 5454, 5456, 5754 aluminum hexagonal bar manufacturers in China, focusing on the research and development and production of high-quality products.

Other content readers are interested in

-

5456 Marine Grade Aluminum Plate Sheet

5456 marine grade aluminum plate is an economical choice for ship construction. Can be used on baseboards, decks and other upper fittings.

-

5754 Marine Grade Aluminum Plate Sheet

5754 marine grade aluminum plate is an aluminum alloy designed specifically for marine applications with excellent corrosion resistance and high strength.

-

5456-H111 aluminum alloy is commonly used in the marine and shipbuilding industries, particularly in environments that require resistance to seawater corrosion.

-

5456-H112 aluminum alloy is a cold-processed and heat-treated aluminum alloy, primarily used in fields that require high corrosion resistance and moderate strength, such as the marine and shipbuilding industries.

-

5456 aluminum alloy is a high-strength aluminum alloy widely used in marine, shipbuilding, offshore engineering, and other corrosion-resistant structural components.

-

5456 H32 aluminum alloy is widely used in the marine and shipbuilding industries. It has good corrosion resistance and is suitable for anti-corrosion structural components in seawater environments.

-

5456 H321 aluminum alloy is a high-strength aluminum alloy primarily used in the marine and shipbuilding industries, especially for corrosion-resistant structures in seawater environments.

-

5456 O aluminum alloy is a state of the 5456 series, referring to the aluminum alloy that has been fully annealed (O state).

-

5754 aluminum sheet is a non-heat-treatable alloy in the 5xxx series, with magnesium as its main alloying element. It is well-known for its excellent corrosion resistance, high strength, and good weldability, making it suitable for a wide range of industrial applications.

-

AW 5754 H111 refers to a specific aluminum-magnesium alloy in the 5000 series, known for its excellent corrosion resistance, medium strength, and good weldability.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5454 aluminum alloy not only possesses excellent corrosion resistance, but its unique high-temperature stress resistance makes it irreplaceable in welded structures for ship fuel tanks and high-temperature environments.

-

6061 marine aluminum has good corrosion resistance, high strength, good machinability and welding performance, and is suitable for marine structural parts.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

More content of interest to readers

5456 Aluminum Properties 5049-H24 Aluminum vs. 5754-H24 Aluminum 5754-H14 Aluminum vs. 5754-H22 Aluminum 5754-H22 Aluminum vs. 5754-H32 Aluminum 5754-H28 Aluminum vs. 5754-O Aluminum 5383-O Aluminum vs. 5456-O Aluminum 5383-H32 Aluminum vs. 5456-H32 Aluminum 5383-H111 Aluminum vs. 5456-H111 Aluminum 5383 Aluminum vs. 5456 Aluminum 5383-H112 Aluminum vs. 5456-H112 Aluminum 5456-H116 Aluminum vs. 5456-H32 Aluminum 5086 Aluminum vs. 5456 Aluminum 5456-H112 Aluminum vs. 5456-H116 Aluminum 5456-H111 Aluminum vs. 5456-H116 Aluminum The application of 5456 aluminum plate in shipbuilding Marine grade aluminum 5052 5454 plate for shipbuilding

You might be interested in: Marine Aluminum 5456 Marine Aluminum 5454 Marine Aluminum 5754