Marine Grade Aluminum Round Bar 5754 5454 5456

Marine-grade aluminum round bars are commonly used in shipbuilding, marine engineering, and other applications closely related to water due to their excellent corrosion resistance and strength, making them suitable for use in harsh environments.

5454 aluminum alloy is an Al-Mg anti-rust aluminum with medium strength and excellent corrosion resistance. Its strength is about 20% higher than that of 5052, and its characteristics are generally similar to those of 5154, but it exhibits better corrosion resistance than 5154 in harsh environments. 5454 aluminum alloy has good welding and processing performance, and its strength can be improved through cold working, although this reduces its ductility.

- Corrosion Resistance: 5454 aluminum alloy has excellent corrosion resistance to seawater and some organic acids, making it particularly suitable for marine environments and other corrosive working conditions.

- Processing Performance: This alloy is easily formed through extrusion, rolling, and forging processes, and can be strengthened by cold working. It has good welding performance and can be joined by TIG welding, resistance welding, etc., with minimal strength loss after welding.

5754 aluminum alloy belongs to the Al-Mg series and is a medium-strength anti-rust aluminum. The main alloying element is magnesium (Mg content 2.6-3.6%), with small amounts of manganese (Mn 0.50%) and chromium (Cr 0.30%). This alloy is characterized by good corrosion resistance, weldability, and ease of forming, making it a typical alloy among Al-Mg alloys.

- Corrosion Resistance: 5754 aluminum alloy has good corrosion resistance, especially in marine environments.

- Processing Performance: This alloy has excellent formability and can be cold- or hot-worked into various profiles and plates. It also has outstanding weldability, making it one of the best weldable aluminum alloys.

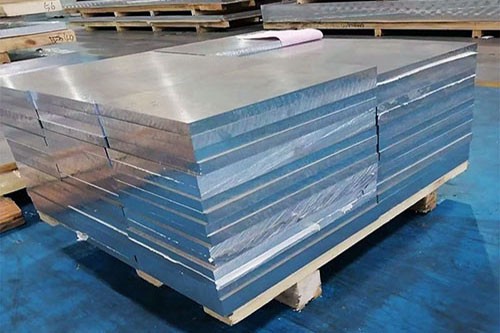

5456 aluminum alloy is an Al-Mg anti-rust aluminum (5B05 has slightly higher magnesium content than 5A05) with strength comparable to 5A03. It cannot be strengthened by heat treatment and has high plasticity in the annealed state. The main alloying element is magnesium (Mg content 4.7-5.7%), with appropriate amounts of manganese (Mn 0.20-0.6%) and titanium (Ti 0.15%).

- Corrosion Resistance: 5456 aluminum alloy has high corrosion resistance and is especially suitable for use in marine environments.

- Processing Performance: This alloy has high plasticity in the annealed state and medium plasticity during semi-cold hardening. It has acceptable welding performance for hydrogen atomic welding, spot welding, gas welding, and TIG welding. Its machinability is poor in the annealed state but fair during semi-cold hardening.

The quality of 5754, 5456, and 5454 marine-grade aluminum round bars fully meets the ship classification standards worldwide: CCS, DNV, NK, ABS, BV, LR, KR.

The specification of 5456 5454 5754 marine grade round bar

| Alloy | 5456 5454 5754 |

| Temper | O, H112 |

| Diameter | 8-320MM |

| Length | 1000mm-6000mm |

| Standard | GB/T 26006-2010 GB/T14846-2008 GB/T6892-2015 EN 755 |

-

5754 Aluminum Round Bar

5754 aluminum alloy round bar belongs to the Al-Mg series anti-rust aluminum. Its core advantages lie in its excellent resistance to seawater corrosion, outstanding stress corrosion cracking resistance, good weldability, and easy formability, with medium strength. In the marine shipbuilding field, due to its seawater corrosion resistance, it is widely used in ship structures and offshore facilities, such as hull deck components, cabin frames, and side protection structures. It is particularly suitable for manufacturing components that frequently come into contact with seawater and require high corrosion resistance. After welding, it can be put into stable service without special treatment.

-

5454 Aluminum Round Bar

5454 aluminum alloy round bar is an Al-Mg series alloy with moderate strength, good corrosion resistance, and weldability, as well as excellent formability. In marine shipbuilding, it is mainly used for non-critical structural parts of ships, such as bulkhead brackets inside the cabin, pipe fasteners, and lightweight door frames. It can maintain stable performance in marine environments, meeting the ship’s requirements for component lightweighting and basic corrosion resistance.

-

5456 Aluminum Round Bar

5456 aluminum alloy round bar is one of the higher-strength varieties in the Al-Mg series, with extremely outstanding seawater corrosion resistance, good weldability, and the ability to withstand large loads. In the field of marine shipbuilding, it is often used for key components of the ship’s main structure, such as hull frameworks of small vessels, deck load-bearing beams, and side support structures of offshore working boats. It is especially suitable for scenarios with strict requirements on strength and seawater corrosion resistance, enabling long-term resistance to seawater erosion and maintaining structural stability.

Chemical Composition of 5456 5454 5754 Alloy

| Chemical Elements | 5456 | 5454 | 5754 |

| Si | 0.25 | 0.25 | 0.4 |

| Fe | 0.4 | 0.4 | 0.4 |

| Cu | 0.1 | 0.1 | 0.1 |

| Mn | 0.50-1.00 | 0.50-1.00 | 0.5 |

| Mg | 4.70-5.50 | 2.40-3.00 | 2.60-3.60 |

| Cr | 0.05-0.20 | 0.05-0.20 | 0.3 |

| Zr | - | - | - |

| Zn | 0.25 | 0.25 | 0.2 |

| Ti | 0.2 | 0.2 | 0.15 |

| Al | Remainder | Remainder | Remainder |

Property of 5456 5454 5754 Alloy

| Alloy | Temper | Diameter/mm | Tension Strength/(N/mm2) | Yield Strength /(N/mm2) | Elongation/% | |

| A | A50 mm | |||||

| Not less than | ||||||

| 5754 | O | ≤150.00 | 180-250 | 80 | 17 | 15 |

| H112 | ≤150.00 | 180 | 80 | 14 | 12 | |

| >150.00-250.00 | 180 | 70 | 13 | - | ||

| 5456 | O | ≤12.50 | 285-365 | 130 | - | 14 |

| >12.50-150.00 | 285-365 | 130 | 12 | - | ||

| H112 | ≤12.50 | 300 | 130 | - | 12 | |

| >12.50-150.00 | 300 | 130 | 10 | - | ||

| 5454 | O | ≤12.50 | 200-275 | 85 | - | 16 |

| >12.50-200.00 | 200-275 | 85 | 18 | - | ||

| H112 | ≤12.50 | 230 | 100 | - | 14 | |

| >12.50-200.00 | 230 | 100 | 16 | - | ||

| ≤12.50 | 180 | 80 | - | 12 | ||

| >12.50-150.00 | 180 | 80 | 14 | - | ||

| >150.00-250.0 | 180 | 70 | 13 | - | ||

Applications of 5456, 5454, and 5754 Aluminum Round Bars in Marine Fields

5454 Aluminum Round Bars

5454 aluminum alloy is an ideal material for shipbuilding in marine environments due to its excellent seawater corrosion resistance and medium strength.

Applications of 5454 Aluminum Round Bars in Shipbuilding

- Ship internal flooring structures and frameworks

- Offshore wind power equipment structural components

- Seawater treatment equipment components

- Ship decks and superstructures

- Interior decorative and structural parts of ships

Advantages of 5454 Aluminum Round Bar:

- Excellent seawater corrosion resistance, especially against seawater and some organic acids

- Good weldability, compatible with various common welding methods, with minimal strength loss after welding

- Medium strength, meeting the mechanical performance requirements of ship structures

- Good low-temperature toughness, suitable for cold environments

5754 Aluminum Round Bars

5754 aluminum alloy, due to its excellent corrosion resistance, weldability, and medium strength, also finds wide use in shipbuilding.

Applications of 5754 Aluminum Round Bars in Shipbuilding

- Ship structures and offshore facilities

- Internal ship structural components

- Seawater pipeline systems

- Housings for marine instruments and equipment

- Refrigerated transport equipment

Advantages of 5754 Aluminum Round Bar:

- Excellent seawater corrosion resistance, suitable for marine environments

- Excellent weldability, one of the best among aluminum alloys

- Medium strength, meeting mechanical requirements for ship structures

- Excellent formability, capable of being processed into various profiles and plates using multiple techniques

5456 Aluminum Round Bars

5456 aluminum alloy is a key material in shipbuilding for the marine sector due to its high strength and excellent corrosion resistance.

Applications of 5456 Aluminum Round Bars in Shipbuilding

- Ship hulls and superstructures

- Offshore platform structural components

- High-strength welded structures

- Ship decks and bulkheads

- Interior decorative parts of ships

Advantages of 5456 Aluminum Round Bar:

- High strength, with tensile strength exceeding 420 MPa

- Excellent seawater corrosion resistance, suitable for marine environments

- Good weldability, suitable for TIG welding and other methods

- Good processing performance, can be manufactured into various shapes through multiple processing techniques

Considerations for Purchasing 5456, 5454, and 5754 Aluminum Round Bars

Strict Dimensional Accuracy Control:

Clearly define the exact specifications of the round bar required, including diameter and length (and wall thickness if tubular).

Clearly communicate tolerance requirements (diameter tolerance, length tolerance, roundness, straightness, etc.). These requirements must be based on detailed design drawings and shipbuilding application standards.

Mandatory Material Certification:

Suppliers must provide valid documentation (material certificates) proving that the aluminum round bars comply with classification society certification standards (such as DNV GL, LR, ABS, BV, CCS, etc.).

Confirm that the material grade (5456/5454/5754) and condition (such as H111, O, etc.) fully meet the classification society standards specified by the project.

Core Quality and Performance Verification:

Focus on verifying whether key performance indicators of the aluminum round bars meet the standards, especially strength (tensile, yield), seawater corrosion resistance, and weldability.

Request and review the material test certificate (MTC/CoC) provided by the supplier, which should clearly list chemical composition, mechanical test results (in accordance with classification society requirements), and other key data.

Select Reliable Suppliers with Caution:

Give preference to suppliers with a strong reputation and successful supply record in the shipbuilding industry.

Evaluate the supplier’s quality management system certification (e.g., ISO 9001) and its effectiveness.

Refer to reviews and feedback from other clients.

Comprehensive Consideration of Price and Delivery:

Compare quotes from different suppliers under the premise of meeting quality and technical requirements.

Ensure pricing is reasonable and transparent, and strictly confirm whether the delivery time can meet the project schedule. Avoid sacrificing quality or facing delivery delays due to low prices.

Ensure Transport and Packaging Safety:

Suppliers must take sufficient protective packaging measures (such as secure bundling, end protection, moisture-proofing, impact protection) to ensure aluminum round bars remain undamaged, undeformed, and uncontaminated during long-distance transport and handling.

Define transport responsibilities and inspection procedures clearly.

Clearly Communicate Special Requirements:

If there are any non-standard requirements, such as special surface treatments (e.g., passivation), specific cutting lengths, end processing, special markings, or additional inspection reports (e.g., UT testing), be sure to confirm feasibility and extra costs with the supplier in writing before placing the order.

Other Applications of 5456, 5454, and 5754 Aluminum Round Bars

Diversified Applications of 5454 Aluminum Round Bars

Automotive Manufacturing

Automotive body structures, wheels, fuel tanks and pipelines, truck body panels

Construction Field

- Building curtain walls

- Decorative structural components

- Roof drainage systems

- Fasteners for buildings

Diversified Applications of 5754 Aluminum Round Bars

Automotive Manufacturing

- Automotive industry (car doors, molds, seals)

- Automotive body structures

- Automotive fuel tanks and pipelines

- Automotive interior parts

Construction Field

- Building curtain walls

- Decorative structural components

- Roof drainage systems

- Fasteners for construction use

Diversified Applications of 5456 Aluminum Round Bars

Aerospace

- Aircraft fuel tanks and pipelines

- Aircraft structural components

- Aerospace parts

Automotive Manufacturing

- Automotive body structures

- Automotive interior parts

- Automotive safety components

Selection Guide for 5456, 5454, and 5754 Aluminum Round Bars

Comparison of Material Properties

| Property | 5454 | 5754 | 5456 |

| Main Alloy Elements | Mg 2.4-3.0% | Mg 2.6-3.6% | Mg 4.7-5.7% |

| Mn 0.50-1.0% | Mn 0.50% | Mn 0.20-0.6% | |

| Cr 0.05-0.20% | Cr 0.30% | Ti 0.15% | |

| Tensile Strength | ≥215 MPa (O temper) | 165-265 MPa (H112 temper) | ≥420 MPa (H32 temper) |

| 240-310 MPa (heat-treated temper) | 230 MPa (H32 temper) | ||

| 260 MPa (H34 temper) | |||

| Yield Strength | ≥85 MPa (O temper) | 80-160 MPa (depending on temper) | ≥275 MPa (H32 temper) |

| 110-200 MPa (heat-treated temper) | |||

| Elongation | ≥10% (O temper) | 7-18% (depending on temper) | ≥10% (H32 temper) |

| 10-20% (heat-treated temper) | |||

| Corrosion Resistance | Excellent, especially suitable for seawater environments | Excellent, especially suitable for marine environments | Excellent, suitable for marine environments |

| Weldability | Good, can be welded by various methods | Excellent, one of the best weldable aluminum alloys | Good, can be welded by TIG welding and other methods |

| Workability | Good, can be processed by extrusion, rolling, etc. | Good, can be manufactured into various profiles and plates using multiple processing techniques | Good, high plasticity in annealed state |

Application Selection Guide

Marine Environment Applications

- General ship structures: 5454 or 5754 (cost-effective)

- High-strength ship structures: 5456 (for high strength requirements)

- Seawater treatment equipment: 5454 (excellent seawater corrosion resistance)

- Offshore platform structures: 5456 (high strength and corrosion resistance)

Automotive Manufacturing Applications

- General body structures: 5754 (medium strength and good formability)

- Automotive interior parts: 5754 (good surface finishing performance)

- Automotive fuel tanks and pipelines: 5454 (corrosion resistance and weldability)

- High-strength automotive components: 5456 (for high strength requirements)

Construction Applications

- Building curtain walls: 5454 or 5754 (corrosion resistance and decorative appearance)

- Roof drainage systems: 5454 (corrosion resistance)

- Decorative structural components: 5754 (good surface finishing performance)

- Fasteners for construction use: 5454 (corrosion resistance and strength)

Purchasing Recommendations

When purchasing these three types of aluminum round bars, the appropriate alloy and temper should be selected based on specific application requirements, and the following points should be noted:

- Clarify requirements: Clearly define the application scenario, performance requirements, dimensional tolerances, and surface quality requirements.

- Choose certification: For critical applications such as shipbuilding and pressure vessels, ensure that the material has obtained the relevant certifications.

- Choose supplier: Select an experienced supplier to ensure material quality and stable supply.

- Quality control: Request material quality certificates and test reports from the supplier, and conduct third-party testing if necessary.

- Consider cost: While meeting performance requirements, also consider material and processing costs.

Haomei Marine Grade Aluminum Round Bar Stock

| Description | Specifications (mm) | Alloy | Fixed length(m) |

| Diameter 16 Aluminum Round Bar 5754 | Ф16 | 5754 | 3 |

| Diameter 20 Aluminum Round Bar 5754 | Ф20 | 5754 | 3 |

| Diameter 32 Aluminum Round Bar 5754 | Ф32 | 5754 | 3 |

| Diameter 40 Aluminum Round Bar 5754 | Ф40 | 5754 | 3 |

| Diameter 70 Aluminum Round Bar 5754 | Ф70 | 5754 | 3 |

| Diameter 6 Aluminum Round Bar 5456 | Ф6 | 5456 | 3 |

| Diameter 10 Aluminum Round Bar 5454 | Ф10 | 5454 | 6 |

| Diameter 12 Aluminum Round Bar 5456 | Ф12 | 5456 | 4 |

| Diameter 12 Aluminum Round Bar 5454 | Ф12 | 5454 | 6 |

| Diameter 15 Aluminum Round Bar 5454 | Ф15 | 5454 | 6 |

| Diameter 15 Aluminum Round Bar 5456 | Ф15 | 5456 | 4 |

| Diameter 16 Aluminum Round Bar 5454 | Ф16 | 5454 | 6 |

| Diameter 20 Aluminum Round Bar 5454 | Ф20 | 5454 | 6 |

| Diameter 25 Aluminum Round Bar 5454 | Ф25 | 5454 | 6 |

| Diameter 30 Aluminum Round Bar 5454 | Ф30 | 5454 | 6 |

| Diameter 40 Aluminum Round Bar 5454 | Ф40 | 5454 | 6 |

| Diameter 50 Aluminum Round Bar 5454 | Ф50 | 5454 | 6 |

| Diameter 60 Aluminum Round Bar 5454 | Ф60 | 5454 | 6 |

| Diameter 80 Aluminum Round Bar 5454 | Ф80 | 5454 | 6 |

Recommended for you

-

5456 5454 5754 Marine Grade Aluminum Bar has certification from CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and its quality fully complies with world marine grade standards.

-

As outstanding representatives of the Al-Mg series alloys, 5456, 5454, and 5754 marine-grade aluminum square bars each have unique performance advantages and application scenarios.

-

Haomei Aluminum is one of the leading 5454, 5456, 5754 aluminum hexagonal bar manufacturers in China, focusing on the research and development and production of high-quality products.

Other content readers are interested in

-

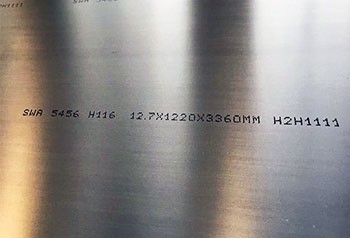

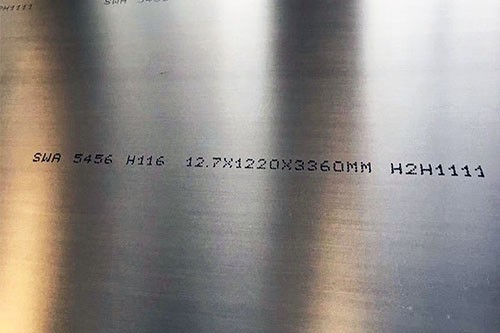

5456 Marine Grade Aluminum Plate Sheet

5456 marine grade aluminum plate is an economical choice for ship construction. Can be used on baseboards, decks and other upper fittings.

-

5754 Marine Grade Aluminum Plate Sheet

5754 marine grade aluminum plate is an aluminum alloy designed specifically for marine applications with excellent corrosion resistance and high strength.

-

5456-H111 aluminum alloy is commonly used in the marine and shipbuilding industries, particularly in environments that require resistance to seawater corrosion.

-

5456-H112 aluminum alloy is a cold-processed and heat-treated aluminum alloy, primarily used in fields that require high corrosion resistance and moderate strength, such as the marine and shipbuilding industries.

-

5456 aluminum alloy is a high-strength aluminum alloy widely used in marine, shipbuilding, offshore engineering, and other corrosion-resistant structural components.

-

5456 H32 aluminum alloy is widely used in the marine and shipbuilding industries. It has good corrosion resistance and is suitable for anti-corrosion structural components in seawater environments.

-

5456 H321 aluminum alloy is a high-strength aluminum alloy primarily used in the marine and shipbuilding industries, especially for corrosion-resistant structures in seawater environments.

-

5456 O aluminum alloy is a state of the 5456 series, referring to the aluminum alloy that has been fully annealed (O state).

-

5754 aluminum sheet is a non-heat-treatable alloy in the 5xxx series, with magnesium as its main alloying element. It is well-known for its excellent corrosion resistance, high strength, and good weldability, making it suitable for a wide range of industrial applications.

-

AW 5754 H111 refers to a specific aluminum-magnesium alloy in the 5000 series, known for its excellent corrosion resistance, medium strength, and good weldability.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5454 aluminum alloy not only possesses excellent corrosion resistance, but its unique high-temperature stress resistance makes it irreplaceable in welded structures for ship fuel tanks and high-temperature environments.

-

6061 marine aluminum has good corrosion resistance, high strength, good machinability and welding performance, and is suitable for marine structural parts.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

More content of interest to readers

5456 Aluminum Properties 5049-H24 Aluminum vs. 5754-H24 Aluminum 5754-H14 Aluminum vs. 5754-H22 Aluminum 5754-H22 Aluminum vs. 5754-H32 Aluminum 5754-H28 Aluminum vs. 5754-O Aluminum 5383-O Aluminum vs. 5456-O Aluminum 5383-H32 Aluminum vs. 5456-H32 Aluminum 5383-H111 Aluminum vs. 5456-H111 Aluminum 5383 Aluminum vs. 5456 Aluminum 5383-H112 Aluminum vs. 5456-H112 Aluminum 5456-H116 Aluminum vs. 5456-H32 Aluminum 5086 Aluminum vs. 5456 Aluminum 5456-H112 Aluminum vs. 5456-H116 Aluminum 5456-H111 Aluminum vs. 5456-H116 Aluminum The application of 5456 aluminum plate in shipbuilding Marine grade aluminum 5052 5454 plate for shipbuilding

You might be interested in: Marine Aluminum 5754 Marine Aluminum 5454 Marine Aluminum 5456