5052 O H112 Marine Grade Aluminum Bar

5052 O H112 Marine Grade Aluminum Rod is a rod made from 5052 aluminum alloy that is fully annealed to improve workability and tempered to provide strength and resistance suitable for marine applications.

5052: Indicates alloy composition. In this case, it's mostly aluminum with smaller amounts of magnesium and chromium. 5052 aluminum is known for its strength and corrosion resistance.

O: The "O" designation refers to the tempered or annealed state of aluminum. In this case, "O" stands for annealed, indicating that the aluminum has been sufficiently annealed to improve its machinability and reduce internal stresses.

H112: This is another status name. "H112" means the aluminum has been strain hardened and stabilized. This is a common condition for marine grade aluminum and provides good strength and resistance to the marine environment.

International classification society certification

CCS, DNV, NK, ABS, BV, LR, KR, RBNA, RS

Mechanical properties of marine 5052 aluminum bar

| Alloy Temper | Inscribed circle diameter/mm | Tensile strength/(N/mm2) | Specified non-proportional tensile strength/(N/mm2) | Elongation after break/% | |

| A | A50 mm | ||||

| not less than | |||||

| 5052 O | ≤12.50 | 170-230 | 70 | - | 15 |

| >12.50 | 170-230 | 70 | 17 | - | |

| 5052 H112 | ≤12.50 | 170 | 70 | - | 13 |

| >12.50 | 170 | 70 | 15 | - | |

Chemical composition of marine grade aluminum 5052 bars

| Chemical composition | |

| Al | Rem |

| Si | ≤0.25 |

| Fe | ≤0.40 |

| Cu | ≤0.10 |

| Mn | ≤0.10 |

| Mg | 2.2-2.8 |

| Cr | 0.15-0.35 |

| Zn | ≤0.10 |

| Note:Each:≤0.05;Total:≤0.15 | |

5052 O H112 Marine Grade Aluminum Bar Machining Tolerances

Machining tolerances for 5052 O H112 Marine Grade Aluminum Rod may vary depending on factors such as the specific requirements of the project, the machining process involved, and the standards followed by the manufacturer.

Diameter Tolerance (Round Bar):

- Typically ranges from +/- 0.005 inches to +/- 0.010 inches, depending on the diameter size and the precision required.

- Width and Height Tolerance (Square Bar):

- Usually within +/- 0.010 inches to +/- 0.020 inches.

Across Flats Tolerance (Hexagon Bar):

Similar to square bar tolerances, typically within +/- 0.010 inches to +/- 0.020 inches.

Length Tolerance:

Commonly falls within +/- 0.125 inches to +/- 0.250 inches, depending on the length of the bar and the specific machining process.

These tolerances are general guidelines only and may vary based on the specific requirements of the project, the capabilities of the processing equipment, and any applicable industry standards or customer specifications.

5052 O H112 Marine Grade Aluminum Bar Applications

5052 marine grade aluminum is a popular alloy known for its excellent corrosion resistance, high strength, and good weldability. Its properties make it ideal for a variety of applications in the marine industry, where durability and resistance to harsh environments are crucial.

5052 O H112 Marine Grade Aluminum Round Bar

Boat Components: 5052 round bars are often used in the construction of various boat components such as railings, cleats, and handles due to their high strength and corrosion resistance.

Masts and Rigging: The round shape of these bars makes them suitable for masts and rigging components where strength and durability are crucial for withstanding the stresses of sailing.

5052 O H112 Marine Grade Aluminum Square Bar

Structural Framing: 5052 square bars find application in structural framing for marine vessels where their straight edges and right angles are advantageous for constructing frames, supports, and braces.

Decking and Flooring: Square bars can be used for decking and flooring applications, providing a sturdy and corrosion-resistant surface for marine environments.

5052 O H112 Marine Grade Aluminum Hexagon Bar

Fasteners and Fittings: Hexagon bars are often employed for the fabrication of fasteners, bolts, and fittings in marine structures. Their hexagonal shape allows for easy gripping and tightening, making them ideal for securing components in place.

Shafts and Propellers: In some cases, hexagon bars are utilized for manufacturing shafts and propellers where their geometry can offer advantages in terms of balance and performance.

5052 Marine Grade Aluminum Rod is available in a variety of shapes to meet the diverse needs of the marine industry, combining strength, corrosion resistance and versatility. Whether structural supports, hardware or propulsion systems, these rods play a vital role in ensuring the reliability and longevity of ships and structures in harsh marine environments.

How to Choose 5052 O H112 Marine Grade Aluminum Bar?

When selecting different shapes of 5052 marine grade aluminum rods for marine applications, several factors should be considered to ensure optimal performance and suitability for the intended use.

5052 O H112 Marine Grade Aluminum Round Bar

- Advantages: Round bars offer excellent strength and corrosion resistance, making them suitable for various marine applications such as boat building, ship structures, and offshore platforms.

- Considerations: Round bars are versatile and can be easily machined, welded, and formed to fit specific design requirements. They provide uniform stress distribution, which is beneficial in structural applications where load-bearing capabilities are crucial.

5052 O H112 Marine Grade Aluminum Square Bar

- Advantages: Square bars provide enhanced stability and structural support compared to round bars, making them ideal for applications requiring rigidity and precise alignment.

- Considerations: Square bars offer increased surface area contact when compared to round bars, which can be advantageous in applications where secure fastening or attachment is necessary. They are commonly used in marine construction for braces, support beams, and framing components.

5052 O H112 Marine Grade Aluminum Hexagon Bar

- Advantages: Hexagon bars offer a balance between strength and weight, making them suitable for applications where weight reduction is a priority without compromising structural integrity.

- Considerations: The unique shape of hexagon bars provides multiple flat surfaces, facilitating easier gripping and handling during installation and maintenance. They are commonly utilized in marine equipment such as propeller shafts, fasteners, and fittings due to their superior torque transmission capabilities.

Factors such as load requirements, structural integrity, corrosion resistance, ease of fabrication and overall performance expectations must be considered when selecting the appropriate shape of 5052 marine grade aluminum rod for a specific marine application.

Recommended for you

-

Marine-grade aluminum square bars 5052 and 5A02 are two commonly used aluminum alloy materials in marine and corrosive environments, known for their excellent corrosion resistance and mechanical properties.

-

The 5052 O H112 aluminum alloy hexagonal bar has excellent corrosion resistance, making it suitable for the manufacture of ship components.

-

5052 aluminum round bars have excellent formability and durability, making them widely used in the manufacturing of ship components.

Other content readers are interested in

-

5052 marine grade aluminium checkered tread plate sheet

5052 Marine Grade Aluminum Checkerboard combines superior corrosion resistance, enhanced traction, lightweight construction and versatility, making it ideal for a variety of marine applications where durability and safety are critical.

-

5052 Marine Grade Aluminum Plate Sheet

In seawater environments, 5052 aluminum alloy has corrosion resistance properties that are unmatched by many other materials.

-

The 5052 O aluminum plate has excellent formability, making it suitable for the complex curved structures and cold-formed components of ship hulls.

-

5052 H32 aluminum sheet is known for its excellent fatigue strength, good weldability, and corrosion resistance, making it particularly suitable for marine environments and vehicle manufacturing.

-

As a professional 5052-H34 aluminum sheet manufacturer, we provide high-quality products that meet AMS 4017 and ASTM B209 standards, specifically designed for the marine, automotive, and aerospace industries.

-

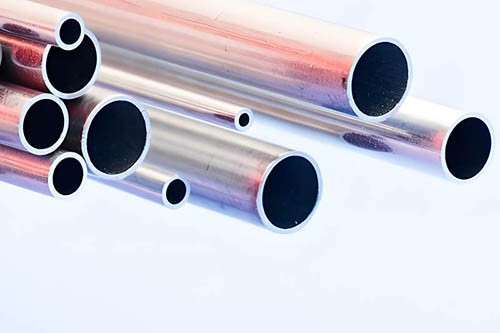

5052 Aluminum Tube Marine Applicability: Resistant to seawater corrosion; ideal for use in marine components. Complies with ASTM/AMS standards and is suitable for the shipbuilding and aerospace industries.

-

5052 Aluminum Rectangular Tube

As a representative of the 5000 series aluminum-magnesium alloys, the 5052 aluminum rectangular tube, with its excellent corrosion resistance, moderate strength, and lightweight characteristics, has become a core material in shipbuilding, aerospace, and the automotive industry.

-

The 5052 aluminum square tube is made from 5052 aluminum alloy and is processed into a square tube. It belongs to the Al-Mg series rust-resistant aluminum alloy.

-

5052 aluminum round tubing is made from 5052 aluminum alloy, which is a round tubular material.

-

5052 H32 aluminum tube is a typical Al-Mg series rust-proof aluminum alloy tube, combining the process of work hardening and stabilization treatment.

-

5052 Drawn Aluminum Tubing is a specialized aluminum alloy product that is manufactured using a cold drawing process, in which the aluminum material is pulled through a die to achieve precise dimensions and a smooth surface.

-

5052-O aluminum tube is made from 5052 aluminum alloy and processed through annealing (O-temper) to form the tubing.

-

Seamless 5052 aluminum tubing is a high-performance material, famous for its outstanding corrosion resistance (especially in marine environments) and its suitability for various structural and fluid handling applications.

-

5052 Aluminum angle is a structural profile made from 5052 aluminum alloy, which is renowned for its excellent corrosion resistance, particularly in marine environments.

-

5052-H32 angle aluminum is an L-shaped structural profile made from 5052 aluminum alloy, which is processed in the H32 temper.

-

5052-H38 is a strain-hardened aluminum-magnesium alloy, known for its high strength, corrosion resistance, and versatility in industrial applications.

-

5052-H36 aluminum alloy is a high-strength, non-heat treatable material in the 5000 series, offering excellent corrosion resistance, especially in marine environments, while also providing good weldability and medium strength.

Recommended for you

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5454 aluminum alloy not only possesses excellent corrosion resistance, but its unique high-temperature stress resistance makes it irreplaceable in welded structures for ship fuel tanks and high-temperature environments.

-

6061 marine aluminum has good corrosion resistance, high strength, good machinability and welding performance, and is suitable for marine structural parts.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

More content of interest to readers

5086 Aluminum vs 5052 5083 vs 5052 Aluminum Sheets A Comprehensive Guide for Marine Uses 5052 Marine Aluminum: How to Improve Its Corrosion Resistance 3003 vs 5052 Marine Grade Sheet Material 5052 aluminum plate thickness standards and selection for shipbuilding 5052 marine-grade aluminum applications and advantages in shipbuilding 5052 and 5083 aluminum characteristics in saltwater Comparison of Marine Aluminum 5052 and 6061 Common marine aluminum plates 5083 5052 Marine grade 5052 checker aluminum plate for ship decks 5052 Marine Aluminum Plate for Yacht Construction 5083 5052 6082 6061 Aluminum sheet metal for boat building Marine grade aluminum 5052 5454 plate for shipbuilding

You might be interested in: Marine Grade Aluminum 5052 5052 aluminum 5052 aluminum sheet 5052 h32 5052 h34 5052 h32 aluminum 5052 aluminum plate 5052 0 aluminum sheet al5052