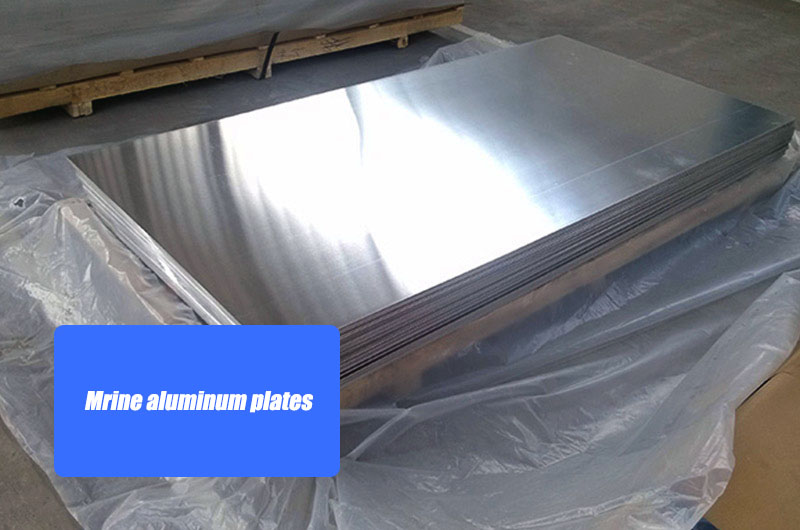

Common marine aluminum plates 5083 5052

Last Updated :

The choice between 5083 and 5052 aluminum alloys in shipbuilding typically depends on the specific usage requirements and environmental conditions. 5083 is usually used in more demanding environments, while 5052 may be used in lighter load conditions or where corrosion resistance requirements are somewhat lower.

Common Marine Aluminum Plates: 5083 vs. 5052 Characteristics

| Characteristics | 5083 Aluminum Alloy | 5052 Aluminum Alloy |

| Corrosion Resistance | Excellent, suitable for marine environments | Good, suitable for marine applications |

| Strength | High, capable of withstanding larger loads | Good, provides sufficient strength |

| Ductility | Average | Better, with good ductility and formability |

| Weldability | Good, suitable for welding | Good, suitable for welding |

| Common Tempers | H111, H112, H321 | H32 |

Characteristics of Marine Aluminum Plates 5083

- Excellent Corrosion Resistance: 5083 aluminum alloy exhibits exceptional corrosion resistance in marine environments, making it suitable for hulls, ship structures, and other components requiring high corrosion resistance.

- High Strength: Provides very high strength, capable of withstanding substantial loads.

- Weldability: Good welding performance, suitable for welding processes.

- Common Tempers: H111, H112, H321.

Characteristics of Marine Aluminum Plates 5052

- Good Corrosion Resistance: 5052 aluminum alloy also shows good corrosion resistance in marine environments, though not as strong as 5083. It is still suitable for marine applications.

- Good Strength and Ductility: Provides sufficient strength while offering good ductility and formability.

- Weldability: Has good welding properties, suitable for welding processes.

- Common Temper: H32.

Common Marine Aluminum Plates 5083 and 5052 Applications

- 5083 Marine Aluminum Plates Applications: Mainly used for hull structures, oil tanks, ship outer panels, and other areas with high corrosion resistance requirements.

- 5052 Marine Aluminum Plates Applications: Widely used in ship structures, ship hulls, oil tanks, cylinder heads, and other areas requiring good corrosion resistance and strength.

5083 Marine Aluminum Plates Applications

- 5083 Aluminum Plate for Hull Structures: Due to its excellent corrosion resistance and high strength, 5083 aluminum alloy is widely used for hull structures, effectively resisting corrosion and wear in marine environments, ensuring long-term stability and safety of the hull.

- 5083 Aluminum Plate for Oil Tanks: In shipboard oil tanks and other storage components, 5083 aluminum alloy is particularly suitable for storing and transporting fuel or other chemicals due to its corrosion resistance, preventing reactions between liquids and the metal surface.

- 5083 Aluminum Plate for Ship Outer Panels: 5083 aluminum alloy is commonly used for the outer panels of ships, including the hull and decks. Its high strength can withstand external impacts and pressures, while its corrosion resistance ensures long-term use in marine environments.

- Other High Corrosion Resistance Components: Any components requiring additional corrosion protection, such as underwater parts of ships, naval structural components, and other parts in contact with seawater, are well-suited for 5083 aluminum alloy. Its durability and reliability in harsh environments make it an ideal choice for these applications.

5052 Marine Aluminum Plates Applications

- 5052 Aluminum Plate for Ship Structures: 5052 aluminum alloy is widely used for structural components in ships, such as frames and support systems. Its good corrosion resistance and moderate strength effectively resist marine environment corrosion while providing necessary structural support.

- 5052 Aluminum Plate for Ship Hulls: 5052 aluminum alloy is used for ship hulls and outer panel components. Its good corrosion resistance protects the hull from seawater erosion while providing sufficient strength to handle various physical stresses in the marine environment.

- 5052 Aluminum Plate for Oil Tanks: In shipboard oil tanks and storage components, 5052 aluminum alloy's corrosion resistance makes it suitable for storing and handling various liquids, including fuel and chemicals, ensuring the durability and reliability of these tanks.

- 5052 Aluminum Plate for Cylinder Heads: 5052 aluminum alloy is also widely used for mechanical parts such as cylinder heads in ships. These components require good mechanical properties and corrosion resistance to ensure long-term stable operation and reduce maintenance needs.

Common marine aluminum plates 5083 5052 chemical composition

Chemical composition of 5083 marine grade aluminum plate

| Element | Composition % |

| Al | REM |

| Si | ≤0.4 |

| Cu | ≤0.10 |

| Mg | 4.0-4.9 |

| Zn | ≤0.25 |

| Mn | 0.40-1.0 |

| Ti | ≤0.15 |

| Cr | 0.05-0.25 |

| Fe | ≤0.40 |

| Note: Single≤0.05; Total≤0.15 | |

Chemical composition of 5052 marine grade aluminum plate

| Element | Chemical composition (%) |

| Al | Rem |

| Si | ≤0.25 |

| Fe | ≤0.50 |

| Cu | ≤0.10 |

| Mn | ≤0.10 |

| Mg | 2.2-2.8 |

| Cr | 0.15-0.35 |

| Zn | ≤0.10 |

| Note:Each:≤0.05;Total:≤0.15 | |

Common marine aluminum plates 5083 5052 mechanical properties

5083 marine aluminum alloy mechanical properties

| Tensile strength (σb) | 110-136MPa |

| Yield strengthσ0.2 (MPa) | ≥110 |

| Elongationδ10 (%) | ≥20 |

| Elastic modulus (E) | 69.3~70.7Gpa |

| Annealing temperature | 415℃ |

5052 marine aluminum alloy mechanical properties

| 5052-O | 5052-H111 | 5052-H112 | 5052-H24 | 5052-H32 | 5052-H34 | |

| Tensile Strength | 79-190 MPa | 75-190 MPa | 89-200 MPa | 190-250 MPa | 180-230 MPa | 200-260 MPa |

| Shear Strength | 130 MPa | 120 MPa | 120 MPa | 150 MPa | 140 MPa | 150 MPa |

| Fatigue Strength | 26 MPa | 66 MPa | 73 MPa | 110 MPa | 120 MPa | 130 MPa |

| Elastic Modulus | 68 GPa | 68 GPa | 68 GPa | 68 GPa | 68 GPa | 68 GPa |

| Brinell Hardness | 47 | 46 | 55 | 67 | 60 | 68 |

| Elongation at Break | 22% | 19% | 10% | 8% | 12% | 10% |

Marine aluminum products you may be interested in

You might be interested in: Marine Grade Aluminum 5083 Marine Grade Aluminum 5052 5 Series Marine Aluminum 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5052 aluminum 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5052 aluminum sheet 5052 h32 5052 h34 5052 h32 aluminum 5052 aluminum plate 5052 0 aluminum sheet al5052 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum