5052 O H112 Marine Grade Aluminum Round Bars

5052 aluminum round bars have excellent formability and durability, making them widely used in the manufacturing of ship components.

5052 aluminum round bars (O temper and H112 temper) are widely used in the manufacturing of ship components, mainly due to their excellent formability and durability.

5052 aluminum round bars are not only suitable for the manufacturing of ship components but also provide excellent corrosion protection and long-term durability in marine environments.

5052 Marine Aluminum Round Bars Material Properties

1. Excellent Formability

5052 aluminum round bars are easy to process into various complex shapes, making them suitable for the manufacturing of ship components. The 5052 aluminum alloy has outstanding cold working properties, especially in the O temper, demonstrating excellent ductility and formability. The H112 temper undergoes some work hardening but still maintains good formability, making it suitable for the manufacture of complex ship components.

2. Excellent Corrosion Resistance

The 5052 alloy has good resistance to seawater and other corrosive environments, making it suitable for ships and marine facilities. Due to its magnesium content, 5052 aluminum alloy is particularly suitable for use in marine environments, exhibiting outstanding salt spray corrosion resistance and seawater corrosion resistance, which is why it is highly suitable for the shipbuilding industry.

3. Good Weldability

5052 aluminum alloy can be welded using various methods, ensuring the strength and corrosion resistance of the welded joints.

4. High Strength and Durability

Although the strength of 5052 aluminum alloy is not as high as that of some other aluminum alloys, its strength-to-weight ratio is very suitable for ship applications.

While the strength of 5052 aluminum is relatively moderate, it can maintain stable performance over time in marine environments, exhibiting good fatigue resistance and durability.

5052 aluminum round bar popular stock sizes

| Description | Diamete (mm) | Alloy | Fixed length(m) |

| 5052 Aluminum Round Bar Ф6 mm Diameter | Ф6 | 5052 | 3 |

| 5052 Aluminum Round Bar Ф10 mm Diameter | Ф10 | 5052 | 6 |

| 5052 Aluminum Round Bar Ф12 mm Diameter | Ф12 | 5052 | 4 |

| 5052 Aluminum Round Bar Ф12 mm Diameter | Ф12 | 5052 | 6 |

| 5052 Aluminum Round Bar Ф15 mm Diameter | Ф15 | 5052 | 6 |

| 5052 Aluminum Round Bar Ф15 mm Diameter | Ф15 | 5052 | 4 |

| 5052 Aluminum Round Bar Ф16 mm Diameter | Ф16 | 5052 | 6 |

| 5052 Aluminum Round Bar Ф20 mm Diameter | Ф20 | 5052 | 6 |

| 5052 Aluminum Round Bar Ф25 mm Diameter | Ф25 | 5052 | 6 |

| 5052 Aluminum Round Bar Ф30 mm Diameter | Ф30 | 5052 | 6 |

| 5052 Aluminum Round Bar Ф40 mm Diameter | Ф40 | 5052 | 6 |

| 5052 Aluminum Round Bar Ф50 mm Diameter | Ф50 | 5052 | 6 |

| 5052 Aluminum Round Bar Ф60 mm Diameter | Ф60 | 5052 | 6 |

| 5052 Aluminum Round Bar Ф80 mm Diameter | Ф80 | 5052 | 6 |

5052 aluminum round bar chemical composition

| Chemical Element | % Present |

| Si | 0.25 max |

| Fe | 0.40 |

| Cu | 0.10 |

| Mn | 0.10 |

| Mg | 2.2 - 2.8 |

| Cr | 0.15 - 0.35 |

| Zn | 0.10 |

| Other (Each) | 0.0 - 0.05 |

| Others (Total) | 0.0 - 0.15 |

| Aluminium (Al) | Balance |

5052 aluminum round bar physical properties

| Physical Property | Value |

| Density | 2.68 g/cm³ |

| Melting Point | 650 °C |

| Thermal Expansion | 24 x10^-6 /K |

| Modulus of Elasticity | 68 GPa |

| Thermal Conductivity | 140 W/m.K |

| Electrical Resistivity | 35 % IACS |

Mechanical properties of marine grade 5052 aluminum round bar

| Temper | Dimension (mm) | Tensile Strength MPa | Yield Strength MPa | Elongation % | Hardness HB |

| O, H111 | Diameter ≤ 80 Width ≤ 60 | Min. 170 Max. 230 | Min. 65 | 20 | 47 |

| H12, H22, H32 | Diameter ≤ 40 | Min. 210 Max. 250 | Min. 160 | 7 | 60 |

| T6 | Diameter ≤ 25 | Min. 230 Max. 270 | Min. 180 | 5 | 68 |

| T64 | Diameter ≤ 15 | Min. 250 Max. 290 | Min. 200 | 3 | 73 |

| T66 | Diameter ≤ 10 | Min. 270 | Min. 220 | 2 | 77 |

5052 Marine Aluminum Round Bars Applications

The 5052 aluminum alloy is widely used in ships and marine equipment due to its excellent corrosion resistance, workability, and moderate strength.

1. Hull Structure

In the framework structure of small vessels, 5052 aluminum round bars are widely used due to their lightweight and durability. Their main functions include:

- Framework components: As supporting and connecting materials for the internal framework of the hull, 5052 aluminum round bars help maintain the strength of the hull without adding excessive weight, ensuring the vessel's stability and maneuverability.

- Connectors: At critical structural points of the hull, 5052 aluminum round bars are often used as connectors to join different structural parts, such as the bottom of the ship to the superstructure and crossbeams to longitudinal beams. Their corrosion-resistant properties ensure long-term use in seawater and humid environments.

2. Marine Accessories

5052 aluminum round bars are also commonly used in the manufacturing of various marine accessories, particularly in the following areas:

- Railings and handrails: Due to the corrosion resistance and good strength of 5052 aluminum, round bars are used to manufacture safety railings and handrails for ships, resisting seawater corrosion while ensuring strength and aesthetics.

- Brackets: Brackets on vessels, such as antenna supports and hatch supports, are often made from 5052 aluminum round bars. These components need to withstand prolonged exposure to outdoor and seawater environments, making 5052 aluminum an ideal choice due to its corrosion resistance.

- Deck accessories: Small deck accessories like masts and rope hooks can also be processed from 5052 aluminum round bars, ensuring they remain functional in harsh marine environments.

3. Marine Hydraulic System Components

The good workability and durability of 5052 aluminum alloy make it highly suitable for various components in marine hydraulic systems:

- Hydraulic pipelines: 5052 aluminum round bars can be processed into hydraulic pipelines, and their corrosion resistance ensures stability and durability in hydraulic oil, seawater, and high-pressure environments.

- Hydraulic brackets: Hydraulic brackets made from aluminum round bars have sufficient strength and are lightweight, adding no extra burden to the vessel while meeting the installation requirements of complex hydraulic systems.

Recommended for you

-

5052 O H112 Marine Grade Aluminum Rod is a rod made from 5052 aluminum alloy that is fully annealed to improve workability and tempered to provide strength and resistance suitable for marine applications.

-

Marine-grade aluminum square bars 5052 and 5A02 are two commonly used aluminum alloy materials in marine and corrosive environments, known for their excellent corrosion resistance and mechanical properties.

-

The 5052 O H112 aluminum alloy hexagonal bar has excellent corrosion resistance, making it suitable for the manufacture of ship components.

Other content readers are interested in

-

5052 marine grade aluminium checkered tread plate sheet

5052 Marine Grade Aluminum Checkerboard combines superior corrosion resistance, enhanced traction, lightweight construction and versatility, making it ideal for a variety of marine applications where durability and safety are critical.

-

5052 Marine Grade Aluminum Plate Sheet

In seawater environments, 5052 aluminum alloy has corrosion resistance properties that are unmatched by many other materials.

-

The 5052 O aluminum plate has excellent formability, making it suitable for the complex curved structures and cold-formed components of ship hulls.

-

5052 H32 aluminum sheet is known for its excellent fatigue strength, good weldability, and corrosion resistance, making it particularly suitable for marine environments and vehicle manufacturing.

-

As a professional 5052-H34 aluminum sheet manufacturer, we provide high-quality products that meet AMS 4017 and ASTM B209 standards, specifically designed for the marine, automotive, and aerospace industries.

-

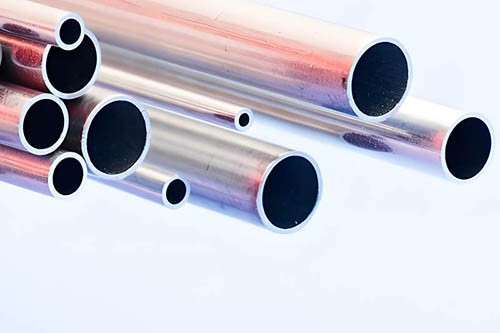

5052 Aluminum Tube Marine Applicability: Resistant to seawater corrosion; ideal for use in marine components. Complies with ASTM/AMS standards and is suitable for the shipbuilding and aerospace industries.

-

5052 Aluminum Rectangular Tube

As a representative of the 5000 series aluminum-magnesium alloys, the 5052 aluminum rectangular tube, with its excellent corrosion resistance, moderate strength, and lightweight characteristics, has become a core material in shipbuilding, aerospace, and the automotive industry.

-

The 5052 aluminum square tube is made from 5052 aluminum alloy and is processed into a square tube. It belongs to the Al-Mg series rust-resistant aluminum alloy.

-

5052 aluminum round tubing is made from 5052 aluminum alloy, which is a round tubular material.

-

5052 H32 aluminum tube is a typical Al-Mg series rust-proof aluminum alloy tube, combining the process of work hardening and stabilization treatment.

-

5052 Drawn Aluminum Tubing is a specialized aluminum alloy product that is manufactured using a cold drawing process, in which the aluminum material is pulled through a die to achieve precise dimensions and a smooth surface.

-

5052-O aluminum tube is made from 5052 aluminum alloy and processed through annealing (O-temper) to form the tubing.

-

Seamless 5052 aluminum tubing is a high-performance material, famous for its outstanding corrosion resistance (especially in marine environments) and its suitability for various structural and fluid handling applications.

-

5052 Aluminum angle is a structural profile made from 5052 aluminum alloy, which is renowned for its excellent corrosion resistance, particularly in marine environments.

-

5052-H32 angle aluminum is an L-shaped structural profile made from 5052 aluminum alloy, which is processed in the H32 temper.

-

5052-H38 is a strain-hardened aluminum-magnesium alloy, known for its high strength, corrosion resistance, and versatility in industrial applications.

-

5052-H36 aluminum alloy is a high-strength, non-heat treatable material in the 5000 series, offering excellent corrosion resistance, especially in marine environments, while also providing good weldability and medium strength.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5454 aluminum alloy not only possesses excellent corrosion resistance, but its unique high-temperature stress resistance makes it irreplaceable in welded structures for ship fuel tanks and high-temperature environments.

-

6061 marine aluminum has good corrosion resistance, high strength, good machinability and welding performance, and is suitable for marine structural parts.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

More content of interest to readers

5086 Aluminum vs 5052 5083 vs 5052 Aluminum Sheets A Comprehensive Guide for Marine Uses 5052 Marine Aluminum: How to Improve Its Corrosion Resistance 3003 vs 5052 Marine Grade Sheet Material 5052 aluminum plate thickness standards and selection for shipbuilding 5052 marine-grade aluminum applications and advantages in shipbuilding 5052 and 5083 aluminum characteristics in saltwater Comparison of Marine Aluminum 5052 and 6061 Common marine aluminum plates 5083 5052 Marine grade 5052 checker aluminum plate for ship decks 5052 Marine Aluminum Plate for Yacht Construction 5083 5052 6082 6061 Aluminum sheet metal for boat building Marine grade aluminum 5052 5454 plate for shipbuilding

You might be interested in: Marine Grade Aluminum 5052 5052 aluminum 5052 aluminum sheet 5052 h32 5052 h34 5052 h32 aluminum 5052 aluminum plate 5052 0 aluminum sheet al5052