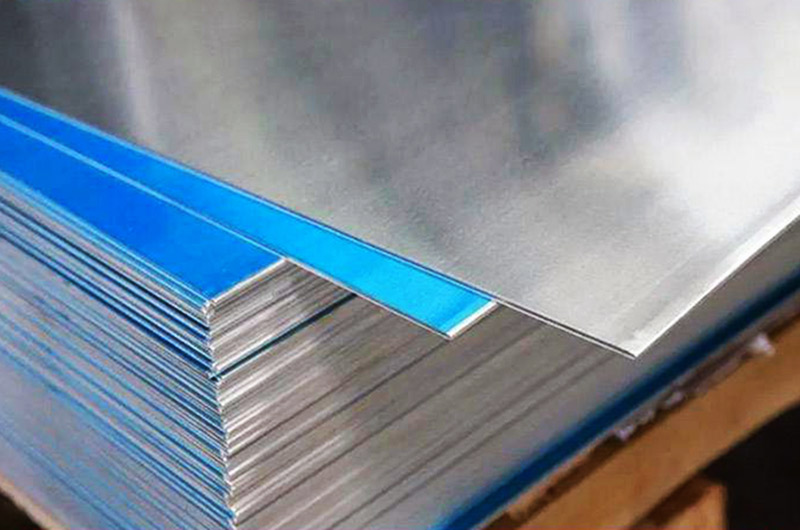

5086 Marine Grade Aluminum Plate Sheet

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

Marine grade aluminum 5086 is often used for underwater parts of ship hulls due to its excellent corrosion resistance and rust resistance.

5086 Marine Grade Aluminum is a specialty alloy with excellent corrosion resistance and strength properties that make it ideal for marine applications.

5086 Marine Grade Aluminum Plate Sheet Features

1. Higher strength: 5086 marine grade aluminum plate generally has higher strength properties compared to 5052 and 5083 aluminum alloys. This increase in strength is due to the higher magnesium content in 5086 alloy, which enhances its overall strength properties. Therefore, 5086 aluminum is often preferred in applications requiring greater structural integrity.

2. Salt water corrosion resistance: 5086 aluminum is known for its excellent corrosion resistance, especially in salt water environments. This resistance is critical for marine applications where there is frequent exposure to seawater and other corrosive elements. The alloy’s corrosion resistance helps extend the service life of marine structures and equipment, reducing maintenance costs and ensuring long-term durability.

3. Easy to form, stamp, and weld: Because 5086 aluminum is not heat treated, it remains relatively soft and ductile, making it easy to form, stamp, and weld. This property allows manufacturers to easily create complex shapes and structures without the need for extensive heat treatment processes. In addition, its excellent weldability creates strong and reliable joints, thereby enhancing the overall integrity of marine components and structures.

In summary, 5086 marine grade aluminum plate offers higher strength, excellent corrosion resistance and ease of fabrication compared to other aluminum alloys such as 5052 and 5083. These properties make 5086 aluminum the first choice for a variety of marine applications, including hulls, decks and other structural components that withstand harsh marine environments.

Why Choose Marine Grade Aluminum 5086?

- 1. Corrosion Resistance: One of the main reasons to choose marine grade aluminum 5086 is its excellent corrosion resistance, especially in harsh marine environments where there is frequent exposure to salt water and other corrosive elements. This resistance helps ensure the longevity and durability of marine structures and vessels.

- 2. Strength and durability: 5086 aluminum has a high strength-to-weight ratio, providing strong structural integrity while remaining relatively lightweight. This strength is essential to withstand the harsh conditions of offshore operations, including rough seas, heavy loads and impacts.

- 3. Weldability: Marine grade aluminum 5086 is easy to weld, allowing for efficient fabrication and construction of marine structures and ships. This solderability facilitates assembly of complex designs and ensures strong, reliable joints.

- 4. Formability: 5086 aluminum has excellent formability, allowing it to be easily formed and manipulated to meet the specific requirements of various marine applications. This versatility allows for the creation of custom components and configurations suitable for different project needs.

- 5. Cost Effective: Despite its superior quality, marine grade aluminum 5086 is cost effective in the long run due to its durability and low maintenance requirements. Its corrosion-resistant properties reduce the need for frequent repairs and replacements, thereby reducing the life cycle costs of marine infrastructure and equipment.

In summary, the unique combination of corrosion resistance, strength, weldability, formability and cost-effectiveness make marine grade aluminum 5086 the first choice for a variety of marine applications, including shipbuilding, offshore structures, hulls and marine equipment.

5086 Marine Grade Aluminum Plate Sheet Specifications

- Alloy: 5086 AlMg4 A5086 EN AW-5086 AMr4/1540 ALMgMn/3.3545 50869(A-G4MC) 5086/A95083

- Standard:GB/T 4437.1-2000

- Temper:O, H112, H116, H111, H321, H32, H36, H38

- Surface Mill finished, bright finish, embossed, coated, etc.

Can provide 5086-h116 aluminum plate

Can provide 5086-h32 aluminum sheet

Can provide 5086 h111 aluminum

Can provide 5086 h34 aluminum

Can provide 5086-h112 aluminum

Application: Ship Board & Siding And Deck Of Ship Side And Bottom

5086, AlMg4, A5086, EN AW-5086 alloys Mechnical Properties

| Alloy | 5086, AlMg4, A5086, | EN AW-5086 | |

| Tensile Strength | σbMpa) | Min.240 | |

| Yield Strengthσ | 0.2Mpa) | Min.100 | |

| Enlogation | (δ5%) | Min.12 | |

AlMg4, A5086, EN AW-5086 alloys aluminum grade 5086 specification

| Alloy Series | 5××× | |

| TypIcial Alloy | 5086, AlMg4, A5086, EN AW-5086 | |

| Typcial Tempe | F, H112 | |

| Thickness | (MM) | 3, 0~12 |

| Width | (MM) | 2000~2600 |

| Length | (MM) | 2000-24000 |

AlMg4, A5086, EN AW-5086 5086 marine grade aluminum specification

| Alloy Series | 5××× | |

| TypIcial Alloy | 5086, AlMg4, A5086, EN AW-5086 | |

| Typcial Tempe | O, H112 | |

| Thickness | (MM) | 3.0~260 |

| Width | (MM) | 1000~3800 |

| Length | (MM) | 2000-38000 |

5086 Marine Grade Aluminum Plate Sheet Chemical Composition

| Alloy | 5086 | |

| Si | ≦0.4 | |

| Fe | ≦0.5 | |

| Cu | ≦0.1 | |

| Mn | 0.20-0.70 | |

| Mg | 3.50-4.50 | |

| Cr | 0.05-0.25 | |

| Zn | ≦0.25 | |

| Ti | ≦0.15 | |

| Zr | - | |

| Standard | EN573 | ASTM b928 |

5086 Marine Grade Aluminum Plate Sheet Mechanical Properties

| Alloy | 5086 | |||

| Temper | O/H111 | H112 | H116 | |

| Rm(Mpa) | Tensile strength | 240-305 | ≥250 | ≥275 |

| Rp0.2(MPa) | Yield strength | ≥95 | ≥125 | ≥195 |

| Elongation | A(%) | ≥16 | ≥8 | ≥10 |

| Exfoliation | corrosion | - | - | ≦PB |

| Intergranular corrosion | Mg/cm2 | - | - | ≦15 |

| Certification | DNV, GL, ABS, CCS, BV, LR | |||

Applications of 5086 Marine Grade Aluminum

5086 marine aluminum plates are commonly used in ship hulls, superstructures, gangways, ramps, transport rollers, and support structures for marine applications.

Boat Body: 5086 aluminum is commonly used in the construction of boat hulls and other watercraft due to its corrosion resistance and strength. It provides durability and longevity in harsh marine environments.

Shipbuilding: Shipbuilders use 5086 aluminum for a variety of components in ship construction, including superstructures, bulkheads and decks, where its corrosion resistance and strength are critical to long-term performance.

Offshore Structures: Offshore platforms, oil rigs and other marine structures benefit from the corrosion resistance and strength of 5086 aluminum, especially in saltwater environments where corrosion protection is critical.

Marine Equipment: A variety of marine equipment and components, such as marine accessories, boat trailers, and offshore wind turbine components, often use 5086 aluminum due to its durability and reliability in marine conditions.

Overall, 5086 marine-grade aluminum combines corrosion resistance, strength, weldability, and formability, making it the material of choice for a variety of marine applications.

5086 Marine Grade Aluminum Plate Sheet Stock List

| Product | Form |

| 5086-H32 Marine Grade Aluminum Sheet 0.032" | Sheet |

| 5086-H32 Marine Grade Aluminum Sheet 0.040" | Sheet |

| 5086-H32 Marine Grade Aluminum Sheet 0.050" | Sheet |

| 5086-H32 Marine Grade Aluminum Sheet 0.063" | Sheet |

| 5086-H321 Marine Grade Aluminum Sheet 0.063" | Sheet |

| 5086-H116 Marine Grade Aluminum Sheet 0.080" | Sheet |

| 5086-H32 Marine Grade Aluminum Sheet 0.090" | Sheet |

| 5086-H116 Marine Grade Aluminum Sheet 0.100" | Sheet |

| 5086-H116 Marine Grade Aluminum Sheet 0.125" | Sheet |

| 5086-H32 Marine Grade Aluminum Sheet 0.125" | Sheet |

| 5086-H116 Marine Grade Aluminum Sheet 0.160" | Sheet |

| 5086-H116 Marine Grade Aluminum Sheet 0.190" | Sheet |

| 5086-H32 Marine Grade Aluminum Sheet 0.190" | Sheet |

| 5086-H116 Marine Grade Aluminum Plate 0.250" | Plate |

| 5086-H116 Marine Grade Aluminum Plate 0.313" | Plate |

| 5086-H116 Marine Grade Aluminum Plate 0.375" | Plate |

| 5086-H32 Marine Grade Aluminum Plate 0.375" | Plate |

| 5086-H116 Marine Grade Aluminum Plate 0.500" | Plate |

| 5086-H32 Marine Grade Aluminum Plate 0.500" | Plate |

| 5086-H116 Marine Grade Aluminum Plate 0.625" | Plate |

| 5086-H32 Marine Grade Aluminum Plate 0.625" | Plate |

| 5086-H116 Marine Grade Aluminum Plate 0.750" | Plate |

| 5086-H116 Marine Grade Aluminum Plate 1.000" | Plate |

| 5086-H116 Marine Grade Aluminum Plate 1.250" | Plate |

| 5086-H116 Marine Grade Aluminum Plate 1.500" | Plate |

| 5086-H116 Marine Grade Aluminum Plate 2.000" | Plate |

| 0.09" Marine Grade Aluminum Sheet 5086-H32 | Sheet |

| 0.063" Marine Grade Aluminum Sheet 5086-H116 | Sheet |

| 0.125" Marine Grade Aluminum Sheet 5086-H32 | Sheet |

| 0.249" Marine Grade Aluminum Sheet 5086-H116 | Sheet |

| 0.19" Marine Grade Aluminum Sheet 5086-H32 | Sheet |

| 0.249" Marine Grade Aluminum Sheet 5086-H32 | Sheet |

Recommended for you

-

As a direct manufacturer of 5086 Aluminum Sheet, we offer marine-grade aluminum plates that meet ASTM B209/EN 485 standards, featuring excellent seawater corrosion resistance and weldability.

-

As a professional aluminum plate manufacturer, we offer high-performance 5086 H116 aluminum alloy plates in a variety of specifications to meet the lightweight and industrial requirements of hulls.

-

As a leading manufacturer of aluminum alloys, we specialize in supplying 5086 H32 aluminum plate, ideal for harsh marine, industrial, and structural applications.

-

Our company specializes in the production of 5086 H111 medium-thick aluminum plates, with a finely polished surface and strong resistance to seawater corrosion. We offer customized cutting and welding services, and provide international certifications such as BV/DNV/ABS, with quick response to custom needs.

Other content readers are interested in

-

5086 marine grade aluminium checkered tread plate sheet

5086 marine grade aluminum checkered tread plate sheet has higher strength and corrosion resistance than 5052 and 5083 plates, making it ideal for many marine and marine applications.

-

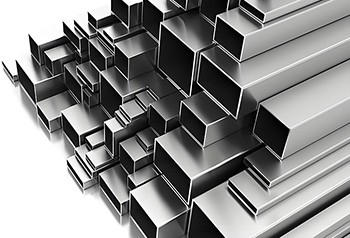

5059 5086 Marine Grade Aluminum Bars

Marine-grade aluminum rods such as 5059 and 5086 combine corrosion resistance, strength and lightweight properties, making them an indispensable material in a variety of marine applications where durability and reliability are important.

-

As a professional manufacturer of 5086 aluminum tubes, we offer seamless cold drawn aluminum tubes that comply with ASTM B210/B221 standards, with material strengthened by magnesium alloys, combining high strength and excellent seawater corrosion resistance.

-

5086 Aluminum Round Tubes and Pipes

As a professional aluminum alloy tube manufacturer, we offer 5086 aluminum alloy seamless round tubes, produced using high-precision cold drawing processes, conforming to international standards such as ASTM B210.

-

As a professional aluminum material manufacturer, we offer high-quality 5086 aluminum alloy square tubes, specifically designed for ships, marine engineering, and high-corrosion environments.

-

5086 Aluminum Drawn Seamless Pipe

As a leading manufacturer of precision aluminum products, we specialize in producing 5086 Aluminum Drawn Seamless Pipes designed for harsh environments.

-

5086 aluminum alloy round bars achieve high strength through cold mechanical processing, offering excellent seawater corrosion resistance and weldability. They are specifically designed for shipbuilding, marine engineering, and transportation equipment.

-

Professional production of 5086 aluminum flat bars, complete product specifications, direct sale from the manufacturer, favorable prices, strict quality control to ensure compliance with ASTM, EN, and other international standards.

-

As a professional aluminum alloy material manufacturer, we offer 5086 H111 aluminum alloy round bars, specially designed for harsh environments, suitable for shipbuilding, marine engineering, and industrial structural fields.

-

As a professional 5086 H32 pipe manufacturer, we provide high-performance, seawater corrosion-resistant customized pipe products, combining excellent strength and lightweight properties. Non-standard size processing is supported, and products are tested according to ISO certification and ASTM/EN standards.

-

As a leading supplier of 5086 aluminum alloy angles, we offer a full range of sizes in 5086-H111 structural angles, suitable for marine ladders, pressure vessels, and transportation equipment.

-

As a professional aluminum material manufacturer, we provide 5086 H111 aluminum alloy angles, combining high strength and excellent corrosion resistance, especially suitable for the marine, offshore engineering, and industrial structural fields.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

More content of interest to readers

What is the difference between 5086 and 6061 aluminum? 5086 H32 vs H116 What is 5086 grade aluminum? 5086 Aluminum vs 5052 5086 Aluminum vs. 5456 Aluminum 5086 and 5083 Aluminum Materials in Shipbuilding

You might be interested in: Marine Aluminum 5086