5383 H34 Aluminum

5383 H34 aluminum alloy is a high-strength aluminum alloy that has undergone strain hardening and stabilization treatments, offering excellent corrosion resistance and weldability. It is widely used in marine, transportation, and construction fields.

5383-H34 aluminum alloy is the form of 5383 aluminum alloy in the H34 condition. The H34 condition indicates that the aluminum alloy has been subjected to strain hardening and then stabilized, giving it a strength level between the annealed (O) condition and the fully hardened (H38) condition. Below is a detailed description of the 5383-H34 aluminum alloy, including its main properties, mechanical performance, and applications.

5383 H34 aluminum alloy is a material with high strength and excellent corrosion resistance, widely used in marine, transportation, and construction sectors. The H34 condition provides a balance of strength and ductility, making it suitable for structural components with strict requirements. Its outstanding weldability and resistance to environmental factors such as corrosion and stress corrosion cracking ensure its good performance in harsh conditions.

5383 H34 Aluminum Corrosion Resistance

As a 5000 series aluminum alloy, 5383-H34 aluminum alloy exhibits excellent corrosion resistance, particularly in marine environments. It has outstanding resistance to pitting and stress corrosion cracking, making it especially suitable for applications exposed to saltwater or other harsh environments over extended periods.

5383 H34 Aluminum Mechanical Properties

| Property | 5383-H34 Aluminum |

| Elastic (Young's, Tensile) Modulus (x 10⁶ psi) | 9.9 |

| Elongation at Break (%) | 6.7 |

| Fatigue Strength (x 10³ psi) | 25 |

| Poisson's Ratio | 0.33 |

| Shear Modulus (x 10⁶ psi) | 3.7 |

| Shear Strength (x 10³ psi) | 31 |

| Tensile Strength: Ultimate (UTS) (x 10³ psi) | 54 |

| Tensile Strength: Yield (Proof) (x 10³ psi) | 45 |

5383 H34 Aluminum Thermal Properties

| Property | 5383-H34 Aluminum |

| Latent Heat of Fusion (J/g) | 390 |

| Maximum Temperature: Corrosion (°F) | 150 |

| Maximum Temperature: Mechanical (°F) | 400 |

| Melting Completion (Liquidus) (°F) | 1200 |

| Melting Onset (Solidus) (°F) | 1010 |

| Specific Heat Capacity (BTU/lb-°F) | 0.22 |

| Thermal Conductivity (BTU/h-ft-°F) | 72 |

| Thermal Expansion (µm/m-K) | 24 |

5383 H34 Aluminum Electrical Properties

| Property | 5383-H34 Aluminum |

| Electrical Conductivity: Equal Volume (% IACS) | 29 |

| Electrical Conductivity: Equal Weight (% IACS) | 97 |

5383 H34 Aluminum Alloy Composition

| Element | 5383-H34 Aluminum |

| Aluminum (Al), % | 92 to 95.3 |

| Chromium (Cr), % | 0 to 0.25 |

| Copper (Cu), % | 0 to 0.2 |

| Iron (Fe), % | 0 to 0.25 |

| Magnesium (Mg), % | 4.0 to 5.2 |

| Manganese (Mn), % | 0.7 to 1.0 |

| Silicon (Si), % | 0 to 0.25 |

| Titanium (Ti), % | 0 to 0.15 |

| Zinc (Zn), % | 0 to 0.4 |

| Zirconium (Zr), % | 0 to 0.2 |

| Residuals, % | 0 |

5383 H34 Aluminum Applications

5383 H34 aluminum alloy, with its excellent mechanical properties and corrosion resistance, is particularly suitable for applications in marine environments and fields that require high strength and corrosion resistance. Its wide application in marine industries, transportation, construction, and pressure vessels demonstrates its reliability and durability in extreme environments.

Marine Industry

One of the main advantages of 5383-H34 aluminum alloy is its excellent corrosion resistance in saltwater environments, making it an ideal material in the marine industry. Due to the strong corrosive nature of the marine environment, 5383-H34 aluminum alloy is commonly used in the following applications:

- Hulls: Used to manufacture the hull structures of ships, providing strength and corrosion resistance to withstand prolonged submersion in water, ensuring the safety and durability of the vessel.

- Decks: Due to its strength and corrosion resistance, 5383-H34 aluminum alloy is widely used in the manufacture of ship decks, especially in areas that are easily exposed to saltwater environments.

- Marine Platforms: In structures such as oil drilling platforms and floating marine platforms, 5383-H34 aluminum alloy provides excellent corrosion resistance and mechanical strength, making it the ideal material for long-term use in offshore facilities.

Transportation

In the transportation sector, the strength, durability, and corrosion resistance of 5383-H34 aluminum alloy make it the material of choice for manufacturing various transport vehicles and structural components. Specific applications include:

- Automotive: Due to its higher strength and lighter weight, 5383-H34 aluminum alloy is commonly used to manufacture automotive structural components, such as body frames and chassis, enhancing vehicle safety, durability, and fuel efficiency.

- Vehicle Frames: In other transportation tools such as trucks and buses, 5383-H34 aluminum alloy provides the necessary strength and stability to ensure the load-bearing capacity of the vehicle.

- Chassis: This alloy is used to manufacture chassis and other components affected by heavy loads, effectively resisting long-term mechanical impacts and corrosion.

Construction Industry

5383-H34 aluminum alloy, with its high strength and corrosion resistance, is an extremely important material in the construction industry. It not only plays a key role in structural aspects but also withstands harsh environments and extreme conditions. Major applications include:

- Construction Machinery: This alloy is commonly used to manufacture critical components for construction machinery, such as support beams and structural frames, ensuring structural stability and durability.

- Structural Beams: In large constructions such as bridges, 5383-H34 aluminum alloy is used in the manufacturing of load-bearing structural beams, capable of withstanding significant pressure and resisting environmental corrosion.

- Bridges: Used in the manufacture of supporting and load-bearing structures, especially in damp or coastal environments, where the alloy's corrosion resistance is crucial.

Pressure Vessels and Storage Tanks

5383-H34 aluminum alloy is also used in fields requiring high strength and resistance to stress corrosion, especially in the manufacture of pressure vessels, storage tanks, and pipelines. Specific applications include:

- Pressure Vessels: In high-pressure environments, the high strength and excellent corrosion resistance of 5383-H34 aluminum alloy make it an ideal material for manufacturing high-pressure containers, often used for industrial liquid and gas storage.

- Storage Tanks and Pipelines: Due to its corrosion resistance, 5383-H34 aluminum alloy is frequently used in the manufacture of storage tanks and pipelines for industries such as oil, chemicals, and food, particularly in environments with high corrosiveness.

5383 H34 Aluminum Weldability and Formability

One important advantage of 5383-H34 aluminum alloy is its excellent weldability. The alloy can be welded using conventional welding methods, and its corrosion resistance remains excellent after welding. Additionally, 5383-H34 aluminum alloy has good formability, making it suitable for the manufacture of complex shapes and structures.

Recommended for you

-

5383 marine grade aluminum plate has excellent corrosion resistance and high strength. Aluminum alloy 5383 is commonly used in shipbuilding and other maritime structures where durability and resistance to salt water corrosion are critical.

-

5383 H112 aluminum is a corrosion-resistant, medium-strength alloy with excellent formability, making it ideal for marine applications. It is also cost-effective for structural components exposed to harsh environments.

-

5383-H321 aluminum has high strength and excellent corrosion resistance, making it suitable for high-load marine applications, especially in environments that require resistance to intergranular corrosion and exfoliation corrosion.

-

5383-H116 aluminum offers good corrosion resistance through specific heat treatment and cold working, making it suitable for light-load marine applications, especially for long-term use in seawater environments.

-

5383-H32 Aluminum is an aluminum alloy that has undergone strain hardening and stabilization treatment, belonging to the aluminum-magnesium alloy series. The "H32" temper indicates that the alloy has been strain-hardened through cold working and then stabilized by appropriate heat treatment, with strength lying between the annealed (O) and full-hard (H38) states.

-

5383-H111 aluminum alloy is a type of aluminum alloy, which undergoes specific heat treatment and mechanical processing to be in the H111 condition. This alloy is widely used in environments that require good corrosion resistance and moderate strength.

-

5383-O aluminum alloy is the annealed (O condition) version of 5383 aluminum. It belongs to the aluminum-magnesium alloy series and has excellent corrosion resistance, particularly outstanding in marine environments.

Other content readers are interested in

-

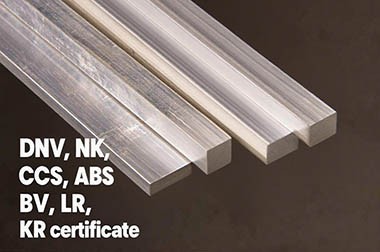

5083 5383 O H112 Marine Grade Aluminum Bars

5083 5383 O H112 Marine Grade Aluminum Bars are certified by CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and their quality fully complies with world marine grade standards.

-

5083 5383 Marine Grade Aluminium Hex Bar

The 5083 and 5383 aluminum hex bars produced by Haomei comply with multiple international and industry standards to ensure product quality and performance meet global application requirements.

-

5083 5383 O H112 Marine Aluminum Square Bar

Haomei Aluminum is capable of producing marine-grade 5083 and 5383 aluminum square bars in O and H112 tempers, certified by major international classification societies including DNV, NK, CCS, ABS, BV, LR, and KR.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

More content of interest to readers

5383-O Aluminum vs. 5456-O Aluminum 5383-H32 Aluminum vs. 5456-H32 Aluminum 5383-H111 Aluminum vs. 5456-H111 Aluminum 5383-H116 Aluminum vs. 5383-H321 Aluminum 5383 Aluminum vs. 5456 Aluminum 5383-H112 Aluminum vs. 5456-H112 Aluminum 5383 Aluminum Hot Rolling Process 5083 vs 5383 Aluminum Alloys: Which is Better for Your Project?

You might be interested in: Marine Aluminum 5383 5 Series Marine Aluminum Aluminum for Boat Aluminum for Shipbuilding