5456 Marine Grade Aluminum Plate Sheet

5456 aluminum alloy is an important member of the aluminum-magnesium alloy family, classified as a non-heat-treatable strengthening alloy. It is closely related to 5356 aluminum alloy but is primarily used for structural applications rather than as a welding filler. As a wrought aluminum-magnesium alloy, 5456 cannot be strengthened through heat treatment but can enhance its mechanical properties through cold working and specific tempering treatments. Due to its excellent corrosion resistance, high strength, and good weldability, it performs well in marine environments and other demanding applications.

The main alloying element of 5456 aluminum plate is magnesium (with a content of up to 5.8–6.8%), supplemented by appropriate amounts of manganese (0.50–0.8%) and chromium (0.05–0.20%). This combination of elements gives the material excellent corrosion resistance and mechanical properties. Compared to other marine-grade aluminum alloys, 5456 offers higher strength and better resistance to stress corrosion cracking, making it especially suitable for use in saltwater environments.

5456 aluminum plate is a forged aluminum-magnesium alloy, belonging to the 5000 series. It is known for its excellent corrosion resistance (especially in marine environments) and higher strength compared to similar products such as 5083.

5456 aluminum plate has enhanced mechanical strength, but it is more sensitive to stress corrosion, especially if improperly treated or exposed to high temperatures for prolonged periods.

Haomei Aluminum 5456 aluminum plate complies with ASTM B928 (marine service), ASTM B209 (sheet/plate), and EN 573-3.

Certified by marine classification societies: DNV, ABS, LR, CCS.

5456 Marine Grade Aluminum Plate Sheet Specifications

| Alloy | 5456 LF10 A5456 ALMg5Mn1 AMr5/1550 EN AW-5456A |

| Temper | O/H116/H321/H111/H112 |

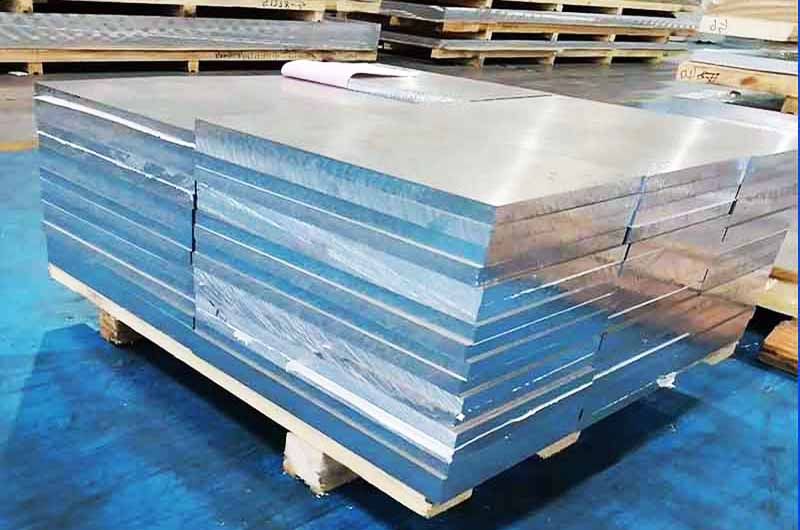

| Thickness(mm) | 3-50 |

| Width(mm) | ≦3600 |

| Shape | Plate, sheet, panel |

| Feature | High Strength Welded Structure |

| Certification | CCS, DNV, NK, CCS, ABS, BV, LR, KR |

Common Thickness Specifications

5456 aluminum plate is available in a variety of thickness specifications to meet different application needs. Based on market availability and industry standards, its commonly used thickness range is as follows:

- Thin plate: 0.008 inches to 0.250 inches (0.2mm to 6.35mm)

- Medium-thick plate: 0.250 inches to 1.0 inch (6.35mm to 25.4mm)

- Thick plate: 1.0 inch to 14.0 inches (25.4mm to 355.6mm)

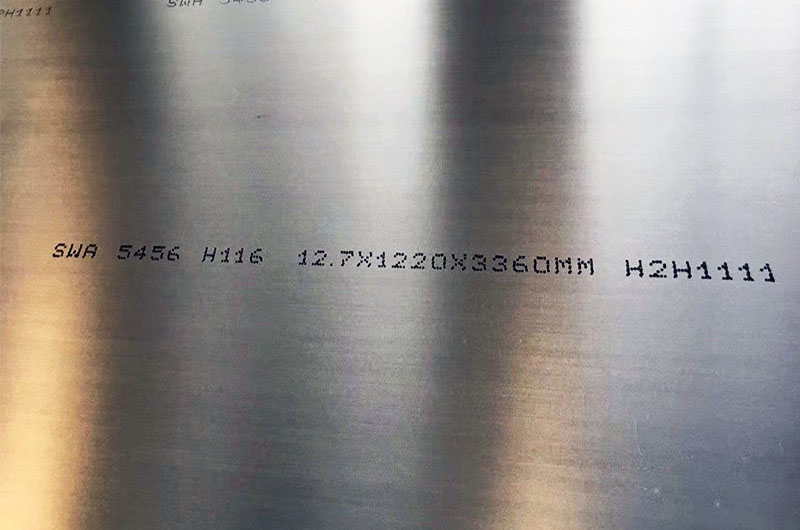

It is worth noting that the standard commercial plate thickness typically ranges from 0.012 inches (0.3mm) to 14.0 inches (355.6mm). In practical applications, the most common thicknesses are 0.125 inches (3.2mm), 0.250 inches (6.4mm), 0.500 inches (12.7mm), and 1.0 inch (25.4mm), with substantial stock available at Haomei Aluminum.

5456 Aluminum Tempers

The temper designation of 5456 aluminum plate represents its processing and heat treatment history, directly affecting its final mechanical properties. The following are common temper states of 5456 aluminum plate and their characteristics:

5456 H116 Temper

- Strain hardened and then partially annealed

- Excellent corrosion resistance, especially stress corrosion cracking resistance

- Maintains good weldability with high weld joint strength

- Typical tensile strength: 330–430 MPa

- Typical yield strength: 280 MPa

- Elongation: about 12%

5456 H321 Temper

- Strain hardened followed by a stabilizing treatment

- Offers higher strength than H116

- Retains good corrosion resistance and weldability

- Suitable for applications requiring higher structural strength

Other Common 5456 Tempers

- H111: Slightly strain hardened, retains good formability

- H34: Cold worked and stabilized, higher strength than H321

- O temper: Fully annealed, highest ductility and lowest strength

Haomei Aluminum 5456 Alloy in Various Tempers Conforms to the Following Standards

International Standards

| Standard Organization | Standard Number | Standard Title |

| ASTM | ASTM B209 | Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate |

| ASTM B221 | Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes | |

| ASTM B928 | Standard Specification for High Magnesium Aluminum-Alloy Sheet and Plate for Marine Service and Similar Environments | |

| ISO | ISO 209 | Aluminum and Aluminum Alloys — Chemical Composition and Forms of Products |

| ISO 6362 | Wrought Aluminum and Aluminum Alloys — Sheets, Strips and Foils — Tolerances on Dimensions and Form | |

| EN | EN 485 | Aluminum and Aluminum Alloys — Sheet, Strip and Plate — Mechanical Properties |

| EN 573 | Aluminum and Aluminum Alloys — Chemical Composition and Form of Wrought Products |

Industry and Military Standards

In addition to international standards, 5456 aluminum plate also complies with various industry and military standards:

- AMS Standards: AMS QQ-A-250/9: Aluminum and Aluminum-Alloy Sheet and Plate

- Classification Society Standards: China Classification Society (CCS), Lloyd's Register (LR), American Bureau of Shipping (ABS)

- Other Industry Standards: Aerospace standards (e.g., SAE AMS), pressure vessel standards (e.g., ASME BPVC)

Characteristics of 5456 Aluminum

Mechanical Properties

5456 aluminum plate exhibits excellent mechanical properties, particularly outstanding among non-heat-treatable alloys:

- High strength: 5456 has significantly higher strength than pure aluminum and many other aluminum alloys, especially in H116 and H321 tempers

- Good toughness: Maintains good toughness and impact resistance even in low-temperature environments

- Moderate hardness: Brinell hardness around 90, offering good wear resistance and machinability

- High fatigue strength: Performs well under cyclic loading, suitable for long-term structural applications

Physical Properties

The physical properties of 5456 aluminum plate enable it to perform well in various environments:

Density

Approximately 2.65 g/cm³, slightly higher than pure aluminum but much lower than steel

Melting Point

568.3–638°C (1055–1180°F), typical for aluminum alloys

Thermal Conductivity

About 150 W/m·K, indicating good heat transfer capability

Electrical Conductivity

Around 35% IACS (International Annealed Copper Standard), moderate conductivity

Coefficient of Thermal Expansion

Approximately 23.5 x 10⁻⁶/°C, similar to other aluminum alloys

Machining Performance

The machining characteristics of 5456 aluminum plate make it suitable for a wide range of manufacturing processes:

- Weldability: Good performance in arc welding, especially gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW)

- Formability: Can be shaped through rolling, extrusion, and other methods, but not suitable for casting

- Machinability: Poor machinability in annealed condition, but significantly improved after cold working

- Surface treatment capability: Attractive surface after anodizing, enhancing corrosion resistance

Corrosion Resistance of 5456 Aluminum

Marine Environment Adaptability

The corrosion resistance of 5456 aluminum plate in marine environments is particularly outstanding and one of its most notable features:

- High salt spray corrosion resistance: Performs excellently in salt spray environments, ideal for long-term seawater exposure

- Stress corrosion cracking resistance: Due to high magnesium content (5.8–6.8%), 5456 offers excellent resistance to stress corrosion cracking

- Seawater resistance: Can withstand long-term humid marine environments, with stable performance in shipbuilding and offshore engineering

- Microbial corrosion resistance: Offers good resistance to attachment and corrosion from marine microorganisms

Corrosion Protection Mechanism

The corrosion resistance of 5456 aluminum plate is derived from its chemical composition and microstructure:

Role of magnesium: High magnesium content forms a dense oxide film that effectively blocks corrosion media

Effect of chromium: The added chromium further enhances resistance to pitting and crevice corrosion

Uniform microstructure: Forging process ensures uniform structure, reducing initiation points for corrosion

Comparison with Other Marine-Grade Aluminum Alloys

Compared with other commonly used marine-grade aluminum alloys, 5456 performs as follows in terms of corrosion resistance:

- Superior to 6061: 5456 has significantly better corrosion resistance than 6061 aluminum alloy

- Comparable to 5083: In most marine environments, the corrosion resistance of 5456 is comparable to 5083, but with higher strength

- Special environment considerations: In some extreme acidic or alkaline environments, additional protective measures may be required

5456 Marine Grade Aluminum Plate Sheet Chemical Composition

| Alloy | 5456 | |

| Si | ≦0.25 | |

| Fe | ≦0.4 | |

| Cu | ≦0.1 | |

| Mn | 0.50-1.0 | |

| Mg | 4.70-5.50 | |

| Cr | 0.05-0.20 | |

| Zn | ≦0.25 | |

| Ti | ≦0.2 | |

| Zr | - | |

| Standard | EN573 | ASTM B928 |

5456 marine aluminum alloy Mechnical Properties

| Alloy | 5456 | |

| Tensile Strength | σbMpa) | ≥420 |

| Yield Strengthσ | 0.2Mpa) | ≥275 |

| Enlogation | (δ5%) | ≥10 |

5456 marine aluminum sheet specification

| TypIcial Alloy | 5456 | |

| Typcial Tempe | F, H112, F | |

| Thickness | (MM) | 3, 0~260 |

| Width | (MM) | 600~2600 |

| Length | (MM) | 1000-24000 |

5456-h116 aluminum specification

| TypIcial Alloy | 5456 | |

| Typcial Tempe | H111 H116 | |

| Thickness | (MM) | 3.0~260 |

| Width | (MM) | 1000~4000 |

| Length | (MM) | 1000-38000 |

5456 Marine Grade Aluminum Plate Sheet product details

Applications of 5456 Aluminum in Shipbuilding

Hull Structure Applications

5456 aluminum plate plays an important role in shipbuilding, especially in hull structures:

Hull shell: 5456 aluminum plates in H116 and H321 tempers are widely used for ship hulls, offering high strength and excellent corrosion resistance

Deck structure: 5456 aluminum plate is suitable for ship decks, especially areas subjected to high stress and harsh marine environments

Bulkheads and partitions: Used in internal bulkheads and partitions of ships, providing structural support and corrosion protection

Superstructures: Superstructures of ships, such as wheelhouses and deckhouses, are commonly built using 5456 aluminum plate

Ship System Applications

In addition to primary structures, 5456 aluminum plate is also used in various ship systems:

Pressure vessels and storage tanks: 5456 is particularly suitable for pressure vessels, storage tanks, and piping systems on ships, especially in saltwater environments

Cooling systems: Due to its excellent thermal conductivity and corrosion resistance, 5456 aluminum plate is used in ship cooling systems and heat exchangers

Ventilation and air conditioning systems: 5456 aluminum plate can be used for ship ventilation ducts and air conditioning systems, providing a lightweight and corrosion-resistant solution

Seawater desalination equipment: In ship seawater desalination systems, 5456 aluminum plate performs excellently and resists seawater corrosion

Advantages in Shipbuilding

The main advantages of using 5456 aluminum plate in shipbuilding include:

Weight reduction: Compared to steel, the lightweight nature of 5456 significantly reduces ship weight and improves fuel efficiency

Lower maintenance costs: Excellent corrosion resistance reduces the need for regular maintenance and coating renewal

Improved safety: High toughness and impact resistance enhance the structural safety of ships

Design flexibility: Good formability and weldability allow for more complex ship designs

Other Applications of 5456 Aluminum

Aerospace Applications

Beyond the marine sector, 5456 aluminum plate also plays an important role in the aerospace industry:

Aircraft structural components

5456 aluminum plate is used in aircraft structural parts, especially where high strength and corrosion resistance are required

Fuel systems

Aircraft fuel tanks and piping systems often use 5456 aluminum plate due to its excellent corrosion resistance and weldability

Spacecraft components

In certain spacecraft applications, 5456 aluminum plate is adopted for its lightweight and high strength characteristics

Cryogenic containers

5456 maintains good performance in low-temperature environments, making it suitable for liquid oxygen and liquid hydrogen containers

Land Transportation Applications

Applications of 5456 aluminum plate in the land transportation sector include:

- Rail Vehicles: 5456 aluminum plates are used in the body structure and interior decoration of subways, light rail, and high-speed trains

- Automobile Manufacturing: Used for automobile body structural parts, chassis components, and decorative parts, offering lightweight and corrosion resistance

- Pressure Vessels: Compressed natural gas (CNG) and liquefied petroleum gas (LPG) tanks on trucks and buses are often made with 5456

- Refrigerated Trucks and Containers: 5456 aluminum plate is used for refrigerated trucks and containers, providing good thermal insulation and corrosion resistance

Architecture and Infrastructure

In the fields of architecture and infrastructure, 5456 aluminum plate is also widely used:

Building Facades

5456 aluminum plates are used for building facades and curtain wall systems, offering aesthetic appeal and long-lasting protection

Roof Structures

In coastal area buildings, 5456 aluminum plate is an ideal choice for roof structures due to its resistance to salt spray corrosion

Bridge Structures

Used in structural components and decorative parts of sea-crossing and coastal bridges

Public Facilities

Commonly used in public facilities of coastal cities, such as railings, signage, and bus shelters, made with 5456 aluminum plates

Industrial and Special Applications

5456 aluminum plate also performs excellently in various industrial and special applications:

- Chemical Equipment: Used in the chemical industry for reactors, storage tanks, and piping systems, especially in corrosive environments

- Pressure Vessels: High-pressure gas and liquid containers, such as fire extinguishers and industrial gas tanks

- Cryogenic Equipment: Equipment and containers operating in cryogenic environments, such as those related to liquefied natural gas (LNG)

- Military Applications: Structural parts and protection systems of military vehicles, naval vessels, and equipment

5456 Aluminum Plate Processing Techniques

Forming Processes

5456 aluminum plate can be processed into desired shapes through various forming techniques:

- Rolling Process: 5456 aluminum plates are primarily produced through hot and cold rolling processes, providing different thicknesses and surface qualities

- Extrusion Forming: 5456 alloy can be extruded into various profiles and tubes

- Bending Forming: In appropriate temper conditions, 5456 aluminum plates can undergo cold or hot bending

- Stamping Forming: Medium-strength 5456 aluminum plates are suitable for various stamping and deep drawing processes

Joining Processes

5456 aluminum plates can be joined by various methods, mainly including:

Welding Processes

5456 aluminum plates can be welded using various methods, among which:

Gas Tungsten Arc Welding (GTAW/TIG) is the most commonly used method, providing high-quality welds

Gas Metal Arc Welding (GMAW/MIG) is suitable for automated welding and thicker plates

Resistance spot welding is suitable for joining thin plates

Mechanical Joining

In some cases, bolting and riveting are also feasible options

Adhesive Bonding

Structural adhesives can be used for bonding, offering good sealing and corrosion resistance

Surface Treatments

Surface treatment of 5456 aluminum plate can further enhance its performance and aesthetics:

Anodizing: Anodizing creates a thick and dense oxide film, significantly improving corrosion and wear resistance

Painting and Coating: Various organic coatings provide additional corrosion protection and decorative effects

Chemical Conversion Coating: Treatments such as chromate or chromate-free processes can enhance paint adhesion and corrosion resistance

Mechanical Surface Treatment: Processes like sandblasting, polishing, and brushing achieve different surface textures and visual effects

Heat Treatment and Cold Working

The heat treatment and cold working characteristics of 5456 aluminum plate are as follows:

Annealing

Full annealing (O temper) achieves maximum ductility and minimum strength

Cold Work Hardening

Strength can be improved through cold working processes such as cold rolling and drawing

Stabilization Treatment

After cold working, low-temperature annealing (stabilization treatment) achieves specific temper states

Notes

5456 aluminum alloy cannot be strengthened by heat treatment (such as quenching and aging), which is a major difference from heat-treatable alloys

As a high-performance aluminum-magnesium alloy, 5456 aluminum plate occupies an important position in shipbuilding, marine engineering, aerospace, and other demanding applications due to its excellent corrosion resistance, high strength, and good processability. Its high magnesium content (5.8–6.8%) and the addition of manganese and chromium provide exceptional seawater corrosion resistance and mechanical properties.

When selecting 5456 aluminum plate, the following factors should be considered based on specific application requirements:

- Temper Selection: Choose the appropriate temper based on strength, formability, and corrosion resistance needs. For example, H116 is suitable for marine environments, while O temper is ideal for maximum formability

- Thickness Selection: Select the proper thickness based on load requirements and application environment. Common thickness ranges from 0.012 inches to 14.0 inches

- Processing Technique Selection: Consider forming and joining methods to ensure compatibility with material characteristics

- Surface Treatment Needs: Choose appropriate surface treatment based on the severity of the corrosion environment

With its unique combination of properties, 5456 aluminum plate has become an ideal solution for marine engineering, shipbuilding, and other high-demand applications, offering lightweight, high strength, and corrosion-resistant performance.

Why choose 5456 for marine grade aluminum plate?

5456 aluminum is ideal for marine and aerospace applications that require a balance of strength, corrosion resistance, and weldability. Haomei Aluminum supplier offers customized sizes (thickness: 3-50 mm, width: ≤3600 mm), and has obtained global project certifications.

- Corrosion resistance: Marine environments are notorious for their corrosive nature, and salt water is particularly harsh. 5456 aluminum plate/sheet has excellent corrosion resistance under these conditions, making it ideal for marine structures, ships and offshore platforms. This resistance is mainly due to the alloying elements used in its composition.

- Strength: 5456 aluminum alloy has good strength properties, allowing it to withstand harsh marine environments. While not as strong as other aluminum alloys such as 5083, it is strong enough for many marine applications. The strength of the material makes it suitable for use in structural components such as hulls, masts and superstructures.

- Weldability: Weldability is a critical factor in marine applications as structures often require complex fabrication and repair. 5456 Aluminum has good weldability, enabling strong and durable welded joints to be formed without compromising its corrosion resistance. Optimum results require proper welding techniques and filler materials that are compatible with 5456 alloy.

- Formability: Marine grade aluminum should be easily formable to accommodate various manufacturing processes and design requirements. This property of 5456 aluminum alloy is crucial for the production of components with complex geometries, such as boat hulls and marine fittings.

Comparison of 5456 Aluminum Plate with Other Alloys

| Comparison with other alloys | Description |

| Compared to 5083-H116 | 5456 aluminum alloy has higher strength than 5083-H116 alloy, but similar corrosion resistance in marine environments. While both exhibit excellent corrosion resistance, especially in seawater and humid conditions, the strength advantage of 5456 makes it more attractive for applications requiring higher load-bearing capacity, making it suitable for shipbuilding and other structural applications. |

| Compared to 6061-T6 | 5456 aluminum alloy has superior corrosion resistance in marine environments compared to 6061-T6 alloy. Especially in seawater and humid conditions, 5456 demonstrates stronger resistance to corrosion, while 6061-T6, with its lower magnesium content, is less resistant. However, 5456 has lower machinability, and 6061-T6 performs better in processing, welding, and forming, making it more suitable for some mechanical and structural applications. |

| Compared to 7075-T6 | 5456 aluminum alloy has lower strength than 7075-T6 alloy but performs better in weldability and corrosion resistance. 7075-T6 is known for its high strength and is commonly used in aerospace, but it has poor weldability and corrosion resistance, especially in marine environments. In contrast, 5456 aluminum alloy, with its excellent corrosion resistance and better weldability, is suitable for applications requiring high durability and strong joints, such as ships and marine structures. |

5456 Specification for Heat Treatment of Marine Aluminum Alloys

5456 Marine Grade Aluminum Plate Sheet is an aluminum-magnesium rust-proof aluminum plate with a strength equivalent to 5A03. Generally used for structural applications, it can be cold worked to produce higher strength. When stored for a long time at temperatures above 65°C, it is prone to spalling and corrosion.

- Homogenization annealing: heating to 480~495℃; holding for 12~14h; furnace cooling.

- Complete annealing: heating to 390~430℃, holding time 30~120min, furnace cooling to 300℃, and air cooling.

- Rapid annealing: heating 350~370℃; holding time 30~120min; air cooling.

- Quenching and aging: Quenching at 495~505℃, water cooling, artificial aging at 185~195℃, 6~12h, air cooling, natural aging: 96h at room temperature.

5456 Aluminum Plate Advantages and Considerations

5456 Aluminum Plate Advantages

- Corrosion Resistance: Performs excellently in saltwater and humid environments, making it more popular in marine applications.

- Strength: Higher strength compared to similar alloys (e.g., 5083), suitable for load-bearing applications.

- Weldability and Formability: Good weldability, easy to manufacture, thereby reducing the overall weight of structures like ships.

5456 Aluminum Plate Limitations

Stress Corrosion Sensitivity: Despite its high strength, the alloy may be more susceptible to stress corrosion when exposed to certain conditions (e.g., prolonged exposure to temperatures above 65°C).

Considerations

- Cannot be heat treated; strength is achieved through cold working.

- Avoid prolonged exposure to temperatures above 65°C to prevent corrosion degradation.

5456 aluminum plate is a strong, corrosion-resistant material that is ideal for marine and structural applications. Its composition (primarily aluminum, with a high magnesium content) results in a material that is both strong and weldable, but attention must be given to stress corrosion and temperature exposure. It meets international standards, making it a reliable choice for high-performance applications in the maritime and aerospace industries.

Precautions for purchasing 5456 marine grade aluminum plate

- Grade certification: Verify whether the aluminum plate meets the 5456 marine grade standard. This ensures that the material has the properties needed to withstand the marine environment.

- Thickness: Determine the aluminum plate thickness required for the application.

- Alloy composition: Understand the alloy composition of 5456 aluminum, which usually contains magnesium as the main alloying element. This composition provides excellent corrosion resistance and strength, which are critical for marine applications.

- Corrosion Resistance: Confirm that aluminum plate has excellent corrosion resistance as this is one of the main reasons to choose marine grade aluminum. The panels should be resistant to salt water corrosion common in marine environments.

- Surface finish: Consider the surface finish of the aluminum plate. Depending on the requirements, boards may be required with a specific surface finish, such as ground or polished, for aesthetic or functional purposes.

- Cost and Budget: Consider the cost of aluminum panels and make sure it fits your budget. While quality is crucial, it is also important to find a balance between quality and cost-effectiveness.

Recommended for you

-

5456-H111 aluminum alloy is commonly used in the marine and shipbuilding industries, particularly in environments that require resistance to seawater corrosion.

-

5456-H112 aluminum alloy is a cold-processed and heat-treated aluminum alloy, primarily used in fields that require high corrosion resistance and moderate strength, such as the marine and shipbuilding industries.

-

5456 aluminum alloy is a high-strength aluminum alloy widely used in marine, shipbuilding, offshore engineering, and other corrosion-resistant structural components.

-

5456 H32 aluminum alloy is widely used in the marine and shipbuilding industries. It has good corrosion resistance and is suitable for anti-corrosion structural components in seawater environments.

-

5456 H321 aluminum alloy is a high-strength aluminum alloy primarily used in the marine and shipbuilding industries, especially for corrosion-resistant structures in seawater environments.

-

5456 O aluminum alloy is a state of the 5456 series, referring to the aluminum alloy that has been fully annealed (O state).

Other content readers are interested in

-

5456 5454 5754 Marine Grade Aluminum Bar

5456 5454 5754 Marine Grade Aluminum Bar has certification from CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and its quality fully complies with world marine grade standards.

-

Marine Grade Aluminum Round Bar 5754 5454 5456

The quality of 5754, 5456, and 5454 marine-grade aluminum round bars fully meets the ship classification standards worldwide: CCS, DNV, NK, ABS, BV, LR, KR.

-

5456 5454 5754 Marine Grade Aluminum Square Bars

As outstanding representatives of the Al-Mg series alloys, 5456, 5454, and 5754 marine-grade aluminum square bars each have unique performance advantages and application scenarios.

-

5454 5456 5754 Marine Grade Hexagonal Aluminum Bar

Haomei Aluminum is one of the leading 5454, 5456, 5754 aluminum hexagonal bar manufacturers in China, focusing on the research and development and production of high-quality products.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

More content of interest to readers

5456 Aluminum Properties 5383-O Aluminum vs. 5456-O Aluminum 5383-H32 Aluminum vs. 5456-H32 Aluminum 5383-H111 Aluminum vs. 5456-H111 Aluminum 5383 Aluminum vs. 5456 Aluminum 5383-H112 Aluminum vs. 5456-H112 Aluminum 5456-H116 Aluminum vs. 5456-H32 Aluminum 5086 Aluminum vs. 5456 Aluminum 5456-H112 Aluminum vs. 5456-H116 Aluminum 5456-H111 Aluminum vs. 5456-H116 Aluminum The application of 5456 aluminum plate in shipbuilding

You might be interested in: Marine Aluminum 5456