5754 Aluminum Sheet

5754 aluminum sheet is a non-heat-treatable alloy in the 5xxx series, with magnesium as its main alloying element. It is well-known for its excellent corrosion resistance, high strength, and good weldability, making it suitable for a wide range of industrial applications.

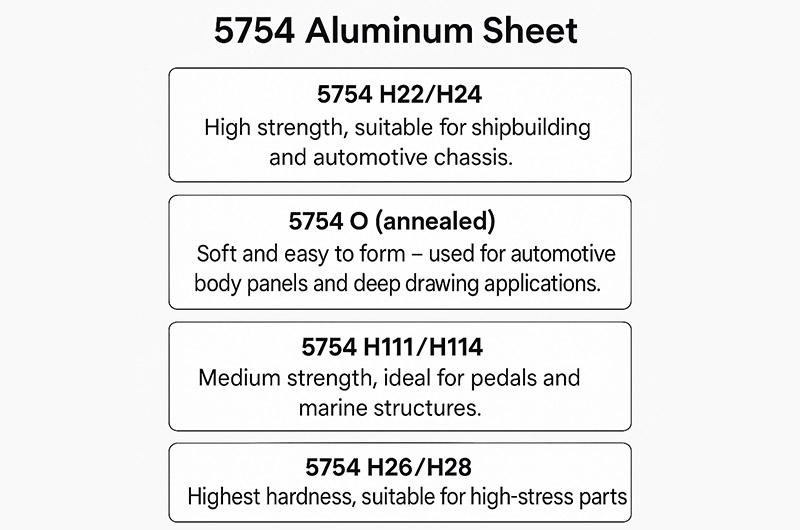

5754 Aluminum Sheet Tempers and Their Applications

5754 aluminum alloy is available in a variety of tempers, each offering a different balance between strength and formability:

- O (Annealed): The softest temper, providing the best ductility and formability.

- H111: Slightly work-hardened, offering improved strength while maintaining good formability.

- H22, H24, H26: Strength increases progressively through cold working, with some reduction in formability.

The choice of temper depends on specific application requirements, aiming for a balance between strength and formability.

| Temper | Characteristics Description | Typical Properties (Relative) | Typical Application Fields |

| O (Annealed) | Softest temper, annealed, excellent ductility, easy to form | Lowest strength, excellent formability | Automotive body panels, deep-drawn parts, complex stretch-formed components |

| H111 | Slight work hardening, retains much of the softness of the annealed state | Low to medium strength, good formability | Hull structures, marine sheets, automotive panels, general industrial structural components |

| H114 | Rolled and hardened, usually in tread plate form | Medium strength, good formability | Anti-slip steps, marine anti-slip decks, footplates, industrial platforms |

| H22 | Work-hardened and moderately tempered, balance of strength and ductility | Medium-high strength | Shipbuilding (decks, structures), automotive chassis, vehicle structural parts |

| H24 | Greater work hardening than H22, offering higher strength | High strength, lower ductility | Hull plates, frame supports, structural reinforcement parts |

| H26 | Higher degree of work hardening, further increased strength | Higher strength, low ductility | High-stress structural components, mechanical load-bearing structures, heavy-duty frames |

| H28 | Maximum work hardening, highest hardness | Highest strength, lowest ductility | High-strength demanding applications, such as high-strength guards, high-load connectors, heavy machinery parts |

Note:

- Degree of work hardening increases in the following order: O < H111 < H114 < H22 < H24 < H26 < H28.

- Recommended for marine applications: H111, H114 (good corrosion resistance + moderate strength).

- Recommended for hull structures: H22, H24 (higher strength).

- Recommended for high load-bearing parts: H26, H28 (maximum strength but poor formability).

- Recommended for deep-drawing complex parts: O temper (soft, extremely formable).

Advantages of 5754 Aluminum Sheet

Corrosion Resistance

Exhibits excellent corrosion resistance in humid and salt spray environments, making it suitable for ships, offshore facilities, and similar applications.

Workability

Easily formed through cold/hot processing, supports stamping, bending, and other complex processes.

Workability can be improved through annealing (heating at 350–440°C, holding for 30–120 minutes).

Weldability

Suitable for conventional welding techniques such as arc welding and resistance welding, providing high weld strength and resistance to cracking.

Chemical Composition of 5754 Aluminum Sheet

The typical chemical composition of 5754 aluminum is as follows:

- Aluminum (Al): Remainder

- Magnesium (Mg): 2.6–3.6%

- Manganese (Mn): ≤ 0.50%

- Chromium (Cr): ≤ 0.30%

- Iron (Fe): ≤ 0.40%

- Silicon (Si): ≤ 0.40%

- Copper (Cu): ≤ 0.10%

- Zinc (Zn): ≤ 0.20%

- Titanium (Ti): ≤ 0.15%

- Others (each): ≤ 0.05%

- Others (total): ≤ 0.15%

Mechanical Properties of 5754 Aluminum Sheet

The mechanical properties of 5754 aluminum vary depending on the temper (hardness). Common tempers include O (annealed), H111, H22, H24, and H26. Typical properties are as follows:

- Tensile Strength: 220–330 MPa

- Yield Strength: 80–250 MPa

- Elongation at Break: 14–16%

- Density: 2.66–2.67 g/cm³

- Young's Modulus: 69 GPa

- Thermal Conductivity: 130–160 W/m·K

- Coefficient of Thermal Expansion: 23.7–23.9 µm/m·K

Characteristics of 5754 Aluminum Sheet

- Corrosion Resistance: Excellent resistance to atmospheric and seawater corrosion makes it ideal for marine and offshore applications.

- Weldability: Good weldability using all standard welding methods, with no adverse effect on corrosion resistance.

- Formability: Good formability in O and H111 tempers, suitable for deep drawing and complex shapes.

- Surface Treatment: Suitable for decorative anodizing, enhancing aesthetic appeal.

5754 Aluminum Sheet Applications

Marine Applications of 5754 Aluminum Sheet

- Hull Structures: Utilized in the construction of boat and ship hulls, 5754 aluminum provides a lightweight yet strong solution that resists corrosion over time .

- Decks and Superstructures: The alloy's strength and corrosion resistance make it suitable for decks and superstructures, ensuring durability and safety .

- Fuel Tanks: 5754 aluminum is employed in the fabrication of fuel tanks due to its ability to withstand the corrosive effects of fuel and seawater .

- Fishing Equipment and Offshore Structures: Its resilience in harsh marine conditions makes it ideal for fishing vessels and offshore platforms .

Temper Variations and Their Marine Uses

5754 aluminum is available in various tempers, each offering different mechanical properties to suit specific marine applications:

- 5754 H111: Provides a balance between strength and formability, suitable for hulls and decks .

- 5754 H22: Offers higher strength, making it ideal for structural components and fuel tanks .

- 5754 O (Annealed): Exhibits maximum ductility, used where complex forming is required .

Comparative Advantage Over Other Alloys

Compared to other aluminum alloys like the 2xxx series, which are more susceptible to corrosion, 5754 aluminum demonstrates superior performance in marine environments. Its magnesium content contributes to its enhanced corrosion resistance, making it a preferred choice for long-term applications in seawater .

5754 aluminum sheet's combination of corrosion resistance, strength, and workability makes it a versatile and reliable material for a wide range of marine applications, from hull construction to offshore structures.

Applications of 5754 Aluminum Sheet

Due to its excellent properties, 5754 aluminum sheet is widely used across various industries:

- Automotive: body panels, doors, roofs, hoods, trunk lids, chassis, and flooring.

- Transportation: railway and truck bodies, trailers, and other transport structures.

- Industrial: food processing equipment, chemical and nuclear structures, and tread plates.

- Architecture: exterior walls, tread plates, roofing, and decorative elements, fully utilizing its anodizing capabilities.

| Field | Specific Application Scenarios |

| Automotive Manufacturing | Doors, molds, seals (utilizing its lightweight and fatigue-resistant characteristics) |

| Transportation | High-speed rail barrier panels, transport tanks (relying on high strength and impact resistance) |

| Architectural Field | Building wall panels, roofing materials (surface can be anodized for aesthetics and durability) |

| Industrial Containers | Pressure vessels, storage tanks (meeting high sealing and pressure resistance requirements) |

Manufacturing and Processing of 5754 Aluminum Sheet

- Weldability: Excellent welding performance using MIG, TIG, and resistance welding; filler alloy 5356 is recommended.

- Machinability: Moderate, but can be machined with standard tools.

- Formability: Cold working processes (rolling, extrusion) can enhance strength, but it is not suitable for heat treatment.

Advantages and Limitations of 5754 Aluminum Sheet

- Advantages: High strength-to-weight ratio, corrosion resistance, and weldability.

- Limitations: Non-heat-treatable, limited to wrought processing (not castable).

Comparison of 5754 Aluminum Sheet with Similar Alloys

- Compared to 5052: 5754 offers higher strength but lower ductility.

- Compared to 6061: 5754 has lower machinability but better corrosion resistance.

Comparison with Other Alloys

| Comparison Item | 5754 Aluminum Sheet | 5052 Aluminum Sheet |

| Magnesium Content | 2.6%-3.6% | 2.2%-2.8% |

| Tensile Strength | 165–265 MPa | 170–245 MPa |

| Typical Applications | High-speed rail barrier panels, ship structures | Electronic enclosures, architectural decoration |

Standards and Designations of 5754 Aluminum Sheet

5754 complies with ASTM B209, EN 485, and ISO 6361 standards, and is also designated as AlMg3 and A95754.

Recommended for you

-

5754 marine grade aluminum plate is an aluminum alloy designed specifically for marine applications with excellent corrosion resistance and high strength.

-

AW 5754 H111 refers to a specific aluminum-magnesium alloy in the 5000 series, known for its excellent corrosion resistance, medium strength, and good weldability.

Other content readers are interested in

-

5456 5454 5754 Marine Grade Aluminum Bar

5456 5454 5754 Marine Grade Aluminum Bar has certification from CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and its quality fully complies with world marine grade standards.

-

Marine Grade Aluminum Round Bar 5754 5454 5456

The quality of 5754, 5456, and 5454 marine-grade aluminum round bars fully meets the ship classification standards worldwide: CCS, DNV, NK, ABS, BV, LR, KR.

-

5456 5454 5754 Marine Grade Aluminum Square Bars

As outstanding representatives of the Al-Mg series alloys, 5456, 5454, and 5754 marine-grade aluminum square bars each have unique performance advantages and application scenarios.

-

5454 5456 5754 Marine Grade Hexagonal Aluminum Bar

Haomei Aluminum is one of the leading 5454, 5456, 5754 aluminum hexagonal bar manufacturers in China, focusing on the research and development and production of high-quality products.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

More content of interest to readers

5049-H24 Aluminum vs. 5754-H24 Aluminum 5754-H14 Aluminum vs. 5754-H22 Aluminum 5754-H22 Aluminum vs. 5754-H32 Aluminum 5754-H28 Aluminum vs. 5754-O Aluminum

You might be interested in: Marine Aluminum 5754