AW 5754 H111

AW 5754 H111 refers to a specific aluminum-magnesium alloy in the 5000 series, known for its excellent corrosion resistance, medium strength, and good weldability.

AW 5754 H111 is a wrought aluminum-magnesium alloy (5xxx series), recognized for its high strength, superior corrosion resistance, and good weldability. The designation "H111" indicates that the alloy has undergone slight strain hardening during forming, but to a lesser extent than required for the H11 temper, making it suitable for applications requiring moderate strength and formability.

EN AW-5754-H111 is an aluminum-magnesium alloy material classified under the European standard (EN) for wrought aluminum alloys. In this designation, "5754" indicates that the primary alloying element is magnesium (approximately 2.6%–3.6%) with a small amount of manganese, while "H111" denotes the material's temper and processing method.

H111 indicates that the material has undergone strain hardening followed by a mild annealing process, which balances the strength increase from cold working with the reduction of residual stress, providing both good formability and dimensional stability. Compared to other tempers (such as H112 or H32), H111 maintains more uniform mechanical properties after processing.

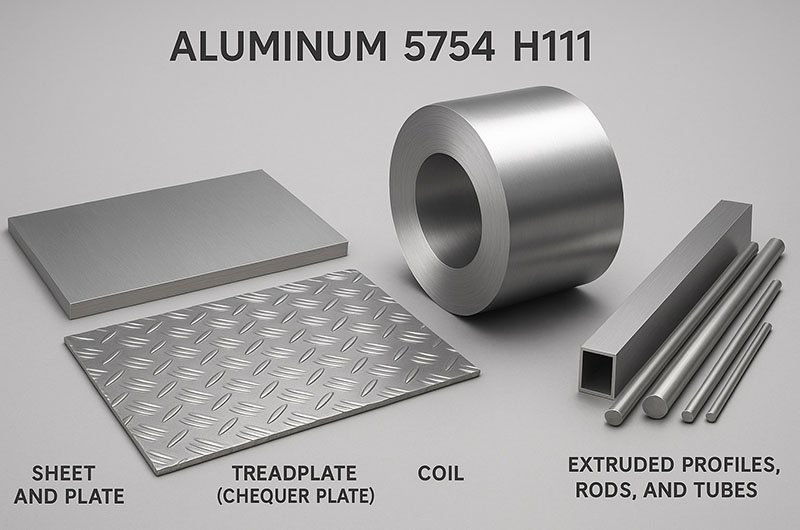

Aluminum 5754 H111 Common Product Forms

The 5754 aluminum in H111 temper is a widely used alloy, known for its excellent corrosion resistance, good weldability, and moderate strength. It is typically available in various product forms to meet different industrial application needs.

5754 Aluminum Sheet and Plate

5754 H111 is widely offered in flat sheet and plate forms, making it suitable for applications such as marine structures, chemical tanks, and flooring where corrosion resistance and formability are essential .

5754 Aluminum Tread plate (Chequer Plate)

This form features a raised pattern, providing enhanced slip resistance. It's commonly used in flooring, vehicle steps, and industrial walkways. The H111 temper offers a balance of strength and formability, making it ideal for such applications .

5754 Aluminum Coil

Aluminium 5754 H111 is also available in coil form, which is beneficial for continuous processing operations like roll forming. This form is often utilized in automotive body panels, pressure vessels, and storage tanks due to its excellent corrosion resistance and weldability .

5754 Aluminum Extruded Profiles, Rods, and Tubes

While less common, 5754 H111 can be found in extruded forms such as rods, bars, tubes, and custom profiles. These are used in structural components where the alloy's strength and corrosion resistance are advantageous .

Key Considerations

Temper: The H111 temper is commonly associated with treadplate and sheet forms, offering a balance of work hardening and formability.

Aluminum 5754 H111 Chemical Composition

According to the EN 573-3 standard, the typical chemical composition of AW 5754 is:

| Element | Percentage (%) |

| Magnesium (Mg) | 2.6 – 3.6 |

| Manganese (Mn) | ≤ 0.50 |

| Iron (Fe) | ≤ 0.40 |

| Silicon (Si) | ≤ 0.40 |

| Chromium (Cr) | ≤ 0.30 |

| Copper (Cu) | ≤ 0.10 |

| Zinc (Zn) | ≤ 0.20 |

| Titanium (Ti) | ≤ 0.15 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

| Aluminium (Al) | Balance |

This composition ensures a balance between strength and corrosion resistance, making it suitable for various applications.

Aluminum 5754 Mechanical Properties (H111 Temper)

The H111 temper indicates that the material is strain-hardened less than H11, typically achieved through minimal cold working. This results in a material that is slightly stronger than the annealed (O) temper but still maintains good ductility.

Typical mechanical properties for AW 5754 H111 are:

| Property | Value |

| Proof Stress (Rp0.2) | ≥ 60 MPa |

| Tensile Strength (Rm) | 160 – 200 MPa |

| Elongation (A50 mm) | ≥ 12% |

| Brinell Hardness (HB) | ~44 |

These properties make it suitable for applications requiring moderate strength and good formability.

Aluminum 5754 H111 Corrosion Resistance

AW 5754 exhibits excellent corrosion resistance, especially in marine environments and industrially polluted atmospheres. This makes it a preferred choice for applications under harsh conditions.

Aluminum 5754 H111 Temper

H111 temper: Achieved by minimizing strain hardening during forming (such as rolling), thereby achieving a balance between formability and strength. It is softer than H22/H26 tempers but easier to form.

Aluminum 5754 H111 Fabrication and Weldability

- Weldability: Excellent; suitable for gas welding, arc welding, and resistance welding.

- Formability: Good; can be easily formed using standard processes.

- Machinability: Fair; while not as easy to machine as some other alloys, it can still be machined with the proper tools.

- Brazability: Poor; not recommended for brazing applications.

These characteristics make AW 5754 H111 suitable for a wide range of manufacturing processes.

Common Applications of Aluminum 5754 H111

Applications of Aluminum 5754 H111 in the Marine Field

Aluminum 5754 H111 is a widely utilized material in marine applications due to its excellent corrosion resistance, moderate strength, and weldability.

Aluminum 5754 H111 for Shipbuilding

5754 H111 is extensively used in constructing ship components such as hulls, decks, bulkheads, and cabin partitions. Its resistance to seawater corrosion makes it ideal for prolonged exposure to marine environments. The alloy is also employed in pressure vessels and storage tanks on ships, where its ability to withstand mechanical stress and chemical exposure is critical . Additionally, its lightweight nature reduces vessel weight, improving fuel efficiency and maneuverability .

Aluminum 5754 H111 for Shipbuilding Offshore Platforms and Marine Structures

For offshore oil rigs and marine infrastructure, 5754 H111 provides durability in harsh conditions. Its high fatigue strength and resistance to industrial pollutants ensure structural integrity in offshore platforms and desalination plants. The alloy is also used in piping systems and diving equipment due to its weldability and corrosion resistance .

Aluminum 5754 H111 for Anti-Slip Flooring (Tread Plates)

The H111 temper enhances the alloy’s strength through strain hardening, making it suitable for tread plates on ship decks and gangways. The textured surface offers anti-slip properties, crucial for safety in wet environments. These plates are also used in vehicle flooring (e.g., trucks, trailers) to combine safety with lightweight design .

Aluminum 5754 H111 for Marine Transportation Components

In high-speed ferries and yachts, 5754 H111 is applied in hydrofoils, portholes, and side panels due to its formability and resistance to saltwater degradation 511. The alloy’s non-magnetic properties and low-temperature ductility further suit specialized marine equipment.

Key Properties Supporting Marine Applications:

Corrosion Resistance: Resists seawater, industrial chemicals, and fuel exposure.

Mechanical Strength: Tensile strength ranges from 160–240 MPa, balancing formability and load-bearing capacity.

Weldability: Compatible with gas, arc, and resistance welding methods.

Surface Quality: Available in mill finish or custom treatments (e.g., mirror polish) for specific needs.

Aluminum 5754 H111 is also applied in which fields

- Industrial Manufacturing: Mold cooling/heating plates, CNC machine tool worktables, vacuum chucks, chemical/nuclear structures, fishing equipment, and food processing, etc.

- Transportation: Automotive parts, ship structural components, vehicle bodies, floors, and pedals.

- Medical and Precision Equipment: Medical device casings, semiconductor equipment components.

- Packaging and Construction: Corrosion-resistant containers, architectural decorative panels.

Aluminum 5754 H111 Physical Properties

| Property | Value |

| Density | 2.66 g/cm³ |

| Melting Point | 595 – 645°C |

| Thermal Conductivity | 130 W/m·K |

| Thermal Expansion | 23.7 µm/m·K |

| Electrical Resistivity | 49 nΩ·m |

| Modulus of Elasticity | 68 GPa |

| Modulus of Rigidity | 26.5 GPa |

These physical properties contribute to its performance in various thermal and structural applications.

AW 5754 H111 is a non-heat-treatable aluminum alloy with medium strength, excellent corrosion resistance, and good weldability, suitable for a wide range of industrial applications.

Comparison of Aluminum 5754 H111 with Other Tempers

H111 vs H26:

- H111: Lower strength (tensile strength: 160-200 MPa) but better formability.

- H26: Higher strength (tensile strength: 265-305 MPa) but lower ductility.

- H111 compared with 5251: Higher magnesium content in 5754, resulting in higher strength.

Aluminum 5754 H111 Standards and Designations

- EN Standards: EN AW-5754, EN 485-2 (mechanical properties).

- Other Names: AlMg3, A95754, 3.3535.

Advantages and Limitations of Aluminum 5754 H111

Advantages of Aluminum 5754 H111

- Outstanding corrosion resistance in marine and industrial environments.

- Lightweight yet strong, ideal for weight-sensitive applications.

- Can be anodized for decorative surface finishes.

Limitations of Aluminum 5754 H111

- Not heat-treatable (common to all 5xxx series alloys).

- Lower hardness compared to fully strain-hardened and aged tempers.

Recommended for you

-

5754 marine grade aluminum plate is an aluminum alloy designed specifically for marine applications with excellent corrosion resistance and high strength.

-

5754 aluminum sheet is a non-heat-treatable alloy in the 5xxx series, with magnesium as its main alloying element. It is well-known for its excellent corrosion resistance, high strength, and good weldability, making it suitable for a wide range of industrial applications.

Other content readers are interested in

-

5456 5454 5754 Marine Grade Aluminum Bar

5456 5454 5754 Marine Grade Aluminum Bar has certification from CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and its quality fully complies with world marine grade standards.

-

Marine Grade Aluminum Round Bar 5754 5454 5456

The quality of 5754, 5456, and 5454 marine-grade aluminum round bars fully meets the ship classification standards worldwide: CCS, DNV, NK, ABS, BV, LR, KR.

-

5456 5454 5754 Marine Grade Aluminum Square Bars

As outstanding representatives of the Al-Mg series alloys, 5456, 5454, and 5754 marine-grade aluminum square bars each have unique performance advantages and application scenarios.

-

5454 5456 5754 Marine Grade Hexagonal Aluminum Bar

Haomei Aluminum is one of the leading 5454, 5456, 5754 aluminum hexagonal bar manufacturers in China, focusing on the research and development and production of high-quality products.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

More content of interest to readers

5049-H24 Aluminum vs. 5754-H24 Aluminum 5754-H14 Aluminum vs. 5754-H22 Aluminum 5754-H22 Aluminum vs. 5754-H32 Aluminum 5754-H28 Aluminum vs. 5754-O Aluminum

You might be interested in: Marine Aluminum 5754