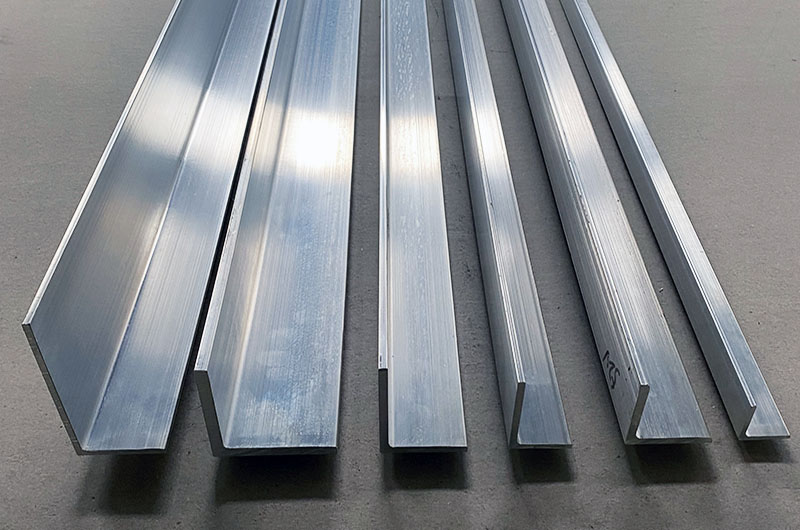

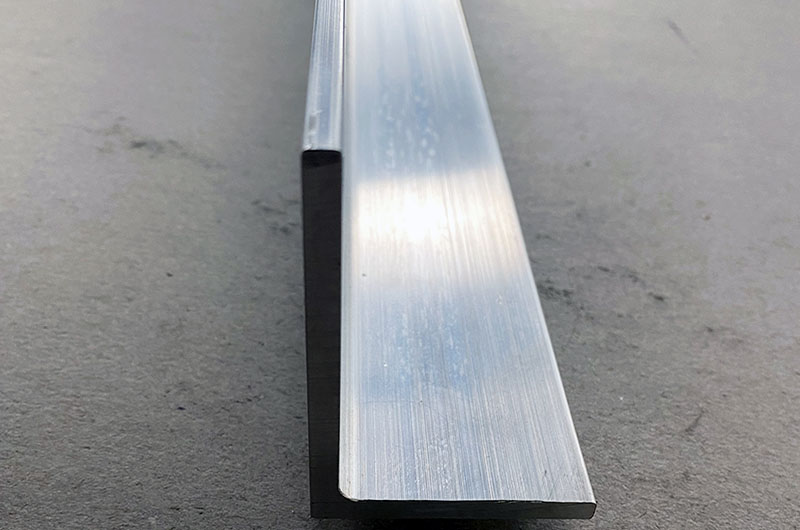

Marine Grade Angular Aluminum

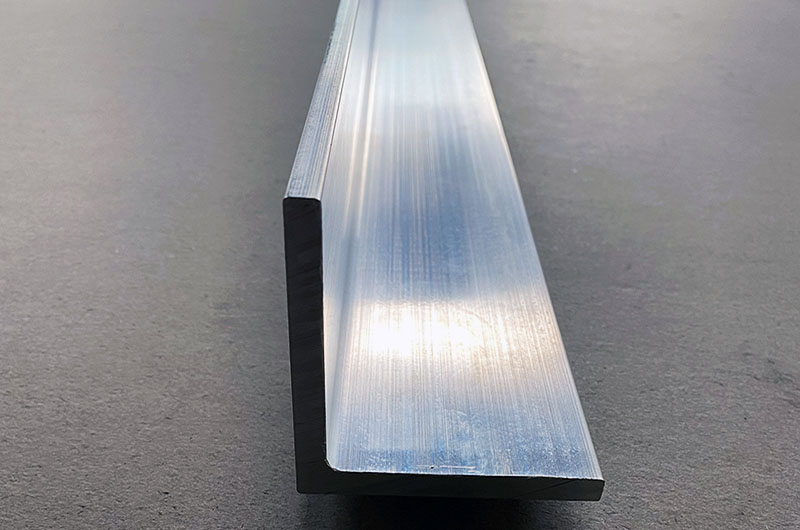

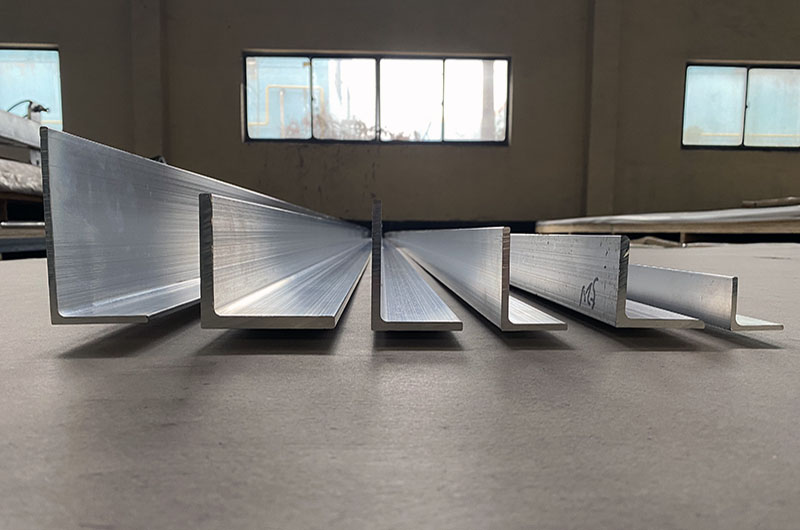

Marine-grade angular aluminum is used for reinforcing edges, frames, and supports in marine structures with L-shaped or angled aluminum profiles. It is valued for its structural support and corrosion-resistant properties.

Marine-grade aluminum angles are L-shaped or angled profiles specifically designed for marine environments. These profiles are crucial for reinforcing the edges, frames, and supports of various marine structures, such as ships, yachts, offshore platforms, and other marine constructions.

Marine-grade aluminum angles are essential components in various marine applications due to their strength, corrosion resistance, and versatility. They are widely used for reinforcing hulls, providing structural support, and enhancing the overall integrity of vessels.

Marine Grade Angular Aluminum Characteristics

1. Corrosion Resistance

The primary advantage of using aluminum angles in marine environments is their excellent corrosion resistance, particularly in saltwater. The alloys used are typically treated or naturally form a protective oxide layer that prevents oxidation and extends the structure's lifespan.

2. Structural Support

Aluminum angles provide essential structural support by reinforcing the edges of decks, frames, and other components. Their L-shaped design allows them to effectively bear loads and distribute stress, which is critical for maintaining the integrity of marine structures.

3. Lightweight and Durable

Despite their light weight, marine-grade aluminum angles possess significant strength, making them an ideal choice for applications where reducing weight without compromising structural integrity is crucial.

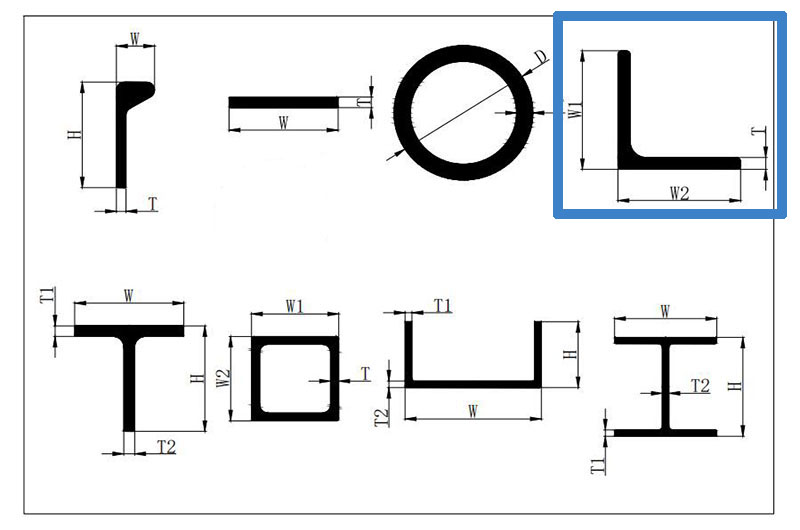

Marine Grade Angular Aluminum Specifications

| Width 1 (W1) mm | 25 | 30 | 40 | 50 | 60 | 70 | 100 | 185 |

| Width 2 (W2) mm | 25 | 30 | 40 | 50 | 50 | 50 | 100 | 50 |

| Thickness (T) mm | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 10 |

Marine Grade Angular Aluminum Common Alloys

Marine-grade angular aluminum is typically made from high-strength, corrosion-resistant aluminum alloys such as 5083, 6061, and 6082. These alloys are chosen for their excellent balance between strength, weight, and saltwater corrosion resistance.

- 5083 Aluminum: Known for its outstanding corrosion resistance and strength, especially in the H111, H112, and H321 tempers.

- 6061 Aluminum: A versatile alloy used in the T6 temper, offering good mechanical properties and ease of welding.

- 6082 Aluminum: Typically used for structural applications, in the T6 temper, providing a good balance of strength and corrosion resistance.

Marine-grade aluminum angles are essential components in shipbuilding and offshore construction, ensuring durability, safety, and long-term performance in harsh marine environments.

Marine Grade Angular Aluminum Surface Treatments

Surface treatments for marine-grade angular aluminum are crucial for ensuring long-term use and maintaining a good appearance in marine environments. Common surface treatments include anodizing and powder coating, both of which significantly enhance the aluminum’s corrosion resistance and longevity.

1. Anodizing

Anodizing is an electrochemical process that forms a layer of aluminum oxide on the surface of the aluminum, increasing its corrosion resistance and hardness. This layer enhances the aluminum’s durability and provides an additional protective coating.

Advantages:

- Corrosion Resistance: The anodized layer significantly improves the aluminum's resistance to salt and moisture in marine environments.

- Wear Resistance: This layer is harder than untreated aluminum surfaces, withstanding higher friction and wear.

- Aesthetics: Anodizing allows for a range of colors and finishes, meeting aesthetic requirements.

2. Powder Coating

Powder coating is a process where powder paint is applied to the aluminum surface and then cured through heating. This coating provides a robust protective layer against environmental factors.

Advantages:

- Corrosion Resistance: Powder coating effectively resists salt and moisture in marine environments.

- Durability: The coating has excellent wear resistance and impact resistance.

- Color and Texture: Offers a wide range of colors and surface textures, customizable to specific needs.

The choice of surface treatment should be based on the specific application environment, budget, and aesthetic requirements. Anodizing is better suited for applications requiring higher wear resistance and a variety of color options, while powder coating is ideal for applications needing cost-effective and good protective performance. In marine environments, ensure the chosen treatment method has adequate corrosion resistance to extend the lifespan of the angular aluminum.

Marine Grade Angular Aluminum Advantages

- 1. Enhances the structural integrity and safety of ships and equipment.

- 2. Reduces maintenance and replacement costs due to durability and resistance to environmental factors.

- 3. Provides customized solutions for unique marine engineering challenges.

Typical Marine Grade Angular Aluminum Chemical Composition

| Element | 5083 Aluminum Alloy (%) | 6061 Aluminum Alloy (%) | 6082 Aluminum Alloy (%) |

| Aluminum (Al) | Remainder | Remainder | Remainder |

| Magnesium (Mg) | 4.0-4.9 | 0.8-1.2 | 0.6-1.2 |

| Silicon (Si) | 0.4-0.7 | 0.4-0.8 | 0.7-1.3 |

| Copper (Cu) | 0.1-0.3 | 0.15-0.40 | 0.1-0.2 |

| Manganese (Mn) | 0.4-0.7 | 0.15-0.40 | 0.4-0.8 |

| Chromium (Cr) | 0.05-0.25 | 0.04-0.35 | 0.05-0.25 |

| Zinc (Zn) | 0.25 (max) | 0.25 (max) | 0.1-0.2 |

| Iron (Fe) | 0.4-0.7 | 0.7 (max) | 0.5 (max) |

| Others | 0.05 (max) | 0.05 (max) | 0.05 (max) |

Typical Marine Grade Angular Aluminum Mechanical Properties

6082 Marine Grade Angular Aluminum Mechanical Properties

| Temper | T6 | T651 |

| Density | 2.70 g/cm³ | 2.68g/cm³ |

| Tensile Strength | 250-310MPa | >=295MPa |

| Elongation | 10% | 8% |

| Thermal Conductivity | 170 W/m-K | 220.0 W/m-K |

6061 Marine Grade Angular Aluminum Mechanical Properties

| Temper | 6061-T6 | 6061-T651 |

| Shear Strength | 210MPa | 210MPa |

| Tensile Strength | 270-310MPa | 270-320 MPa |

| Elastic Modulus | 69GPa | 69GPa |

| Brinell Hardness | 93HB | 93HB |

| Elongation | 10% | 11% |

5083 Marine Grade Angular Aluminum Mechanical Properties

| Tensile strength (σb) | 110-136MPa |

| Yield strengthσ0.2 (MPa) | ≥110 |

| Elongationδ10 (%) | ≥20 |

| Elastic modulus (E) | 69.3~70.7Gpa |

| Annealing temperature | 415℃ |

Marine Grade Angular Aluminum Applications

- Marine grade angular aluminum is used in a wide range of marine applications, including hull reinforcement, deck edges, railing systems, and as supports for various marine equipment. They are also used in custom fabrications that require angled supports.

- Hull Reinforcement: Provides structural support to the hull, enhancing stress and impact resistance.

- Deck Edges: Reinforces deck edges to prevent wear and damage caused by marine conditions and loads.

- Railing Systems: Supports and frames railing systems for safety and aesthetic purposes.

- Supports for Marine Equipment: Used to secure ship equipment such as antennas, lights, and other devices.

Haomei Marine Grade Angular Aluminum Inventory

| Product Name | Specifications (mm) | Brand | Mold No. | Weight per meter (kg/m) | Fixed length(m) | Previous period inventory |

| Angle Aluminum | L25*25*2 | 6082-T6 | YH-HZ-JL25*25*2 | 0.266 | 6 | 445 |

| Angle Aluminum | L25*25*3 | 6082-T6 | YH-HZ-JL25*25*3 | 0.388 | 6 | 1303 |

| Angle Aluminum | L30*30*3 | 6082-T6 | YH-JL30*30*3 | 0.472 | 6 | 78 |

| Angle Aluminum | L30*30*4 | 6082-T6 | YH-HZ-JL30*30*4 | 0.612 | 6 | 152 |

| Angle Aluminum | L32*20*4 | 6082-T6 | YH-HZ-JL32*20*4 | 0.529 | 6 | 307 |

| Angle Aluminum | L40*25*4 | 6082-T6 | YH-HZ-JL40*25*4 | 0.668 | 6 | 149 |

| Angle Aluminum | L40*40*3 | 6082-T6 | YH-JL40*40*3 | 0.629 | 6 | 426 |

| Angle Aluminum | L40*40*4 | 6082-T6 | YH-JL40*40*4 | 0.833 | 6 | 893 |

| Angle Aluminum | L40*40*5 | 6082-T6 | YH-HZ-JL40x40x5 | 1.022 | 6 | 247.5 |

| Angle Aluminum | L45*45*4 | 6082-T6 | YH-HZ-JL45*45*4 | 0.942 | 6 | 184 |

| Angle Aluminum | L45*45*5 | 6082-T6 | YH-HZ-JL45*45*5 | 1.158 | 6 | 206 |

| Angle Aluminum | L45*28*3 | 6082-T6 | YH-HZ-JL45*28*3 | 0.578 | 6 | 138 |

| Angle Aluminum | L45*28*4 | 6082-T6 | YH-HZ-JL45*28*4 | 0.755 | 6 | 153 |

| Angle Aluminum | L50*25*4 | 6082-T6 | YH-HZ-JL50*25*4 | 0.775 | 6 | 437 |

| Angle Aluminum | L50*32*3 | 6082-T6 | YH-JL50*32*3 | 0.651 | 6 | 232 |

| Angle Aluminum | L50*32*4 | 6082-T6 | YH-HZ-JL50*32*4 | 0.855 | 6 | 297 |

| Angle Aluminum | L50*35*3 | 6082-T6 | YH-HZ-JL50*35*3 | 0.674 | 6 | 122 |

| Angle Aluminum | L50*35*5 | 6082-T6 | YH-HZ-JL50*35*5 | 1.093 | 6 | 349 |

| Angle Aluminum | L50*40*5 | 6082-T6 | YH-HZ-JL50*40*5 | 1.161 | 6 | 79 |

| Angle Aluminum | L50*50*3 | 6082-T6 | YH-HZ-JL50*50*3 | 0.796 | 6 | 388 |

| Angle Aluminum | L50*50*4 | 6082-T6 | YH-JL50*50*4 | 1.051 | 6 | 275 |

| Angle Aluminum | L50*50*5 | 6082-T6 | YH-JL50*50*5 | 1.296 | 6 | 194 |

| Angle Aluminum | L50*50*6 | 6082-T6 | YH-HZ-JL50*50*6 | 1.54 | 6 | 250 |

| Angle Aluminum | L56*36*3 | 6082-T6 | YH-JL56*36*3 | 0.733 | 6 | 590 |

| Angle Aluminum | L56*36*4 | 6082-T6 | YH-HZ-JL56*36*4 | 0.964 | 6 | 250 |

| Angle Aluminum | L56*36*5 | 6082-T6 | YH-HZ-JL56*36*5 | 1.19 | 6 | 281 |

| Angle Aluminum | L60*40*4 | 6082-T6 | YH-QC-L60*40*4/4 | 1.051 | 6 | 156 |

| Angle Aluminum | L60*60*6 | 6082-T6 | YH-HZ-JL60*60*6 | 1.867 | 6 | 79 |

| Angle Aluminum | L63*40*4 | 6082-T6 | YH-HZ-JL63*40*4 | 1.084 | 6 | 287 |

| Angle Aluminum | L63*40*5 | 6082-T6 | YH-HZ-28 | 1.339 | 6 | 343 |

| Angle Aluminum | L63*40*6 | 6082-T6 | YH-HZ-29 | 1.589 | 6 | 148 |

| Angle Aluminum | L63*40*7 | 6082-T6 | YH-HZ-JL63*40*7 | 1.834 | 6 | 201 |

| Angle Aluminum | L63*63*4 | 6082-T6 | YH-HZ-JL63*63*4 | 1.332 | 6 | 321 |

| Angle Aluminum | L63*63*4 | 6082-T6 | YH-HZ-JL63*63*4 | 1.332 | 3 | 12 |

| Angle Aluminum | L63*63*5 | 6082-T6 | YH-HZ-JL63*63*5 | 1.65 | 6 | 142 |

| Angle Aluminum | L65*65*6 | 6082-T6 | YH-HZ-JL65*65*6 | 2.031 | 6 | 157 |

| Angle Aluminum | L70*45*4 | 6082-T6 | YH-HZ-JL70*45*4 | 1.214 | 6 | 169 |

| Angle Aluminum | L70*45*5 | 6082-T6 | YH-HZ-JL70*45*5 | 1.502 | 6 | 34 |

| Angle Aluminum | L70*50*5 | 6082-T6 | YH-JL70*50*5 | 1.57 | 6 | 196 |

| Angle Aluminum | L70*50*8 | 6082-T6 | YH-JXC-29 | 2.44 | 6 | 92 |

| Angle Aluminum | L70*70*5 | 6082-T6 | YH-HZ-JL70*70*5 | 1.842 | 6 | 202 |

| Angle Aluminum | L70*70*7 | 6082-T6 | YH-HZ-JL70*70*7 | 2.539 | 6 | 67.5 |

| Angle Aluminum | L75*50*4 | 6082-T6 | YH-JL75*50*4 | 1.325 | 6 | 307 |

| Angle Aluminum | L75*50*5 | 6082-T6 | YH-JL75*50*5 | 1.639 | 6 | 72 |

| Angle Aluminum | L75*50*6 | 6082-T6 | YH-HZ-JL75*50*6 | 1.948 | 6 | 174 |

| Angle Aluminum | L75*50*7 | 6082-T6 | YH-HZ-JL75*50*7 | 2.253 | 6 | 96 |

| Angle Aluminum | L75*50*8 | 6082-T6 | YH-HZ-30 | 2.552 | 6 | 164 |

| Angle Aluminum | L75*75*6 | 6082-T6 | YH-HZ-JL75*75*6 | 2.355 | 6 | 195.5 |

| Angle Aluminum | L75*75*7 | 6082-T6 | YH-HZ-JL75*75*7 | 2.727 | 6 | 160 |

| Angle Aluminum | L76.2*50.8*4.75 | 6082-T6 | YH-HZ-JL76.2*50.8*4.75 | 1.586 | 6 | 224 |

| Angle Aluminum | L80*40*4 | 6082-T6 | YH-HZ-L80*40*4 | 1.268 | 6 | 296 |

| Angle Aluminum | L80*50*5 | 6082-T6 | YH-HZ-JL80*50*5 | 1.706 | 6 | 261 |

| Angle Aluminum | L80*50*6 | 6082-T6 | YH-HZ-JL80*50*6 | 2.028 | 6 | 82 |

| Angle Aluminum | L80*80*8 | 6082-T6 | YH-HZ-JL80*80*8 | 3.314 | 6 | 128 |

| Angle Aluminum | L90*56*5 | 6082-T6 | YH-HZ-JL90*56*5 | 1.926 | 6 | 231 |

| Angle Aluminum | L90*56*6 | 6082-T6 | YH-HZ-JL90*56*6 | 2.291 | 6 | 205.67 |

| Angle Aluminum | L90*56*7 | 6082-T6 | YH-HZ-JL90*56*7 | 2.655 | 6 | 93 |

| Angle Aluminum | L100*50*4 | 6082-T6 | L100*50*4 | 1.595 | 6 | 166 |

| Angle Aluminum | L100*50*5 | 6082-T6 | YH-QC-HZAL-16 | 2.025 | 6 | 115 |

| Angle Aluminum | L100*50*6 | 6082-T6 | YH-HZ-JL100*50*6 | 2.355 | 6 | 124 |

| Angle Aluminum | L101.6*50.8*6.3 | 6082-T6 | YH-HZ-JL101.6*50.8*6.3 | 2.508 | 6 | 32.5 |

| Angle Aluminum | L100*60*8 | 6082-T6 | YH-HZ-JL100*60*8 | 3.314 | 6 | 89 |

| Angle Aluminum | L100*65*6 | 6082-T6 | YH-JL100*65*6 | 2.601 | 6 | 134 |

| Angle Aluminum | L100*75*10 | 6082-T6 | YH5110 | 4.543 | 6 | 75 |

| Angle Aluminum | L100*76*6 | 6082-T6 | YH-HZ-JL100*76*6 | 2.781 | 6 | 18.5 |

| Angle Aluminum | L100*100*6 | 6082-T6 | YH-HZ-JL100*100*6 | 3.172 | 6 | 103 |

| Angle Aluminum | L100*100*10 | 6082-T6 | YH-HZ-JL100*100*10 | 5.174 | 6 | 92 |

| Angle Aluminum | L120*50*4 | 6082-T6 | YH-HZ-JL120*50*4 | 1.815 | 6 | 50 |

| Angle Aluminum | L120*50*8 | 6082-T6 | YH-HZ-JL120*50*8 | 3.527 | 6 | 19 |

| Angle Aluminum | L120*80*8 | 6082-T6 | YH-HZ-JL120*80*8 | 4.18 | 6 | 84 |

| Angle Aluminum | L125*50*6 | 6082-T6 | YH5111 | 2.763 | 6 | 191 |

| Angle Aluminum | L140*80*7 | 6082-T6 | YH-HZ-JL140*80*7 | 4.062 | 6 | 41.5 |

| Angle Aluminum | L140*90*10 | 6082-T6 | YH-HZ-JL140*90*10 | 5.99 | 6 | 10 |

| Angle Aluminum | L140*140*8 | 6082-T6 | YH-HZ-JL140*140*8 | 5.921 | 6 | 28.5 |

| Angle Aluminum | L150*100*5 | 6082-T6 | L150*100*5 | 3.338 | 6 | 58 |

| Angle Aluminum | L165*80*10 | 6082-T6 | YH3010 | 6.434 | 6 | 41.5 |

| Angle Aluminum | L180*50*8 | 6082-T6 | YH-HZ-JL180*50*8 | 4.837 | 6 | 36 |

| Angle Aluminum | L185*50*7 | 6082-T6 | YH-JXC-12 | 4.343 | 6 | 75 |

Recommended for you

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

Marine Grade Flat Aluminum refers to flat, rectangular marine aluminum sheets or strips used in structural components, decks, and other flat surfaces on vessels.

-

Marine Grade T-Type Aluminum Profiles

Marine T aluminum is a type of aluminum profile specifically designed for shipbuilding, primarily used for connecting or reinforcing hull parts at a vertical angle.

-

Marine Grade I-Type Aluminum Profiles

Marine-grade I-beam aluminum: An I-beam or H-beam aluminum profile used in marine applications requiring high strength, typically used in the construction of beams, joists, and structural supports.

-

Marine Grade Aluminum Square Tube

Marine Grade Square Tube: A type of hollow square aluminum profile used in frameworks, railings, and other structural applications where both strength and corrosion resistance are critical.

-

Marine-grade aluminum troughs: A U-shaped or channel profile used in drainage systems, cable management, and structural components in marine environments. They help guide or support materials while resisting corrosion.

-

Marine Grade Aluminum Bulb Flat extrusions

The advantages of Aluminum Bulb Flat Extrusions over other types of extrusions are significant. Compared to traditional extrusions such as angles or flats, bulb flats offer better performance in load distribution and structural reinforcement.