Marine Grade Aluminum Square Tube

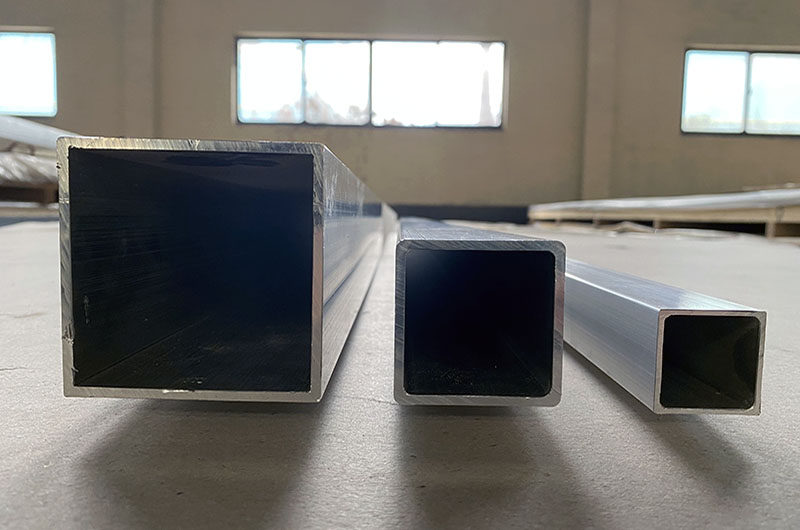

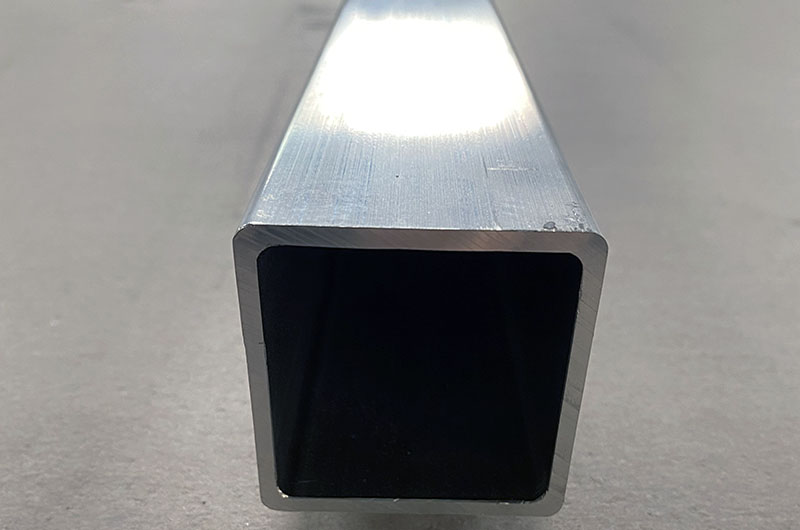

Marine Grade Square Aluminum Tube is a hollow square aluminum profile specifically designed for environments where structural strength and corrosion resistance are crucial.

Marine Grade Square Aluminum Tube is a key component in constructing durable, lightweight, and corrosion-resistant marine structures, providing reliability and longevity in demanding environments.

Marine Grade Aluminum Square Tube Characteristics

- 1. Structural Integrity: The square cross-section of these tubes offers excellent load-bearing capacity, making them an ideal choice for frameworks, supports, and railings in marine environments. The hollow design reduces weight without compromising strength, which is crucial for maintaining the efficiency and stability of ships and structures.

- 2. Corrosion Resistance: These tubes are treated to withstand harsh marine environmental conditions, including exposure to saltwater, UV radiation, and temperature fluctuations. The corrosion resistance of the alloy ensures long-term durability and minimizes maintenance requirements.

- 3. Lightweight Efficiency: Despite their high strength, these tubes are lightweight, contributing to the overall efficiency of marine structures by reducing the weight burden without compromising safety or performance.

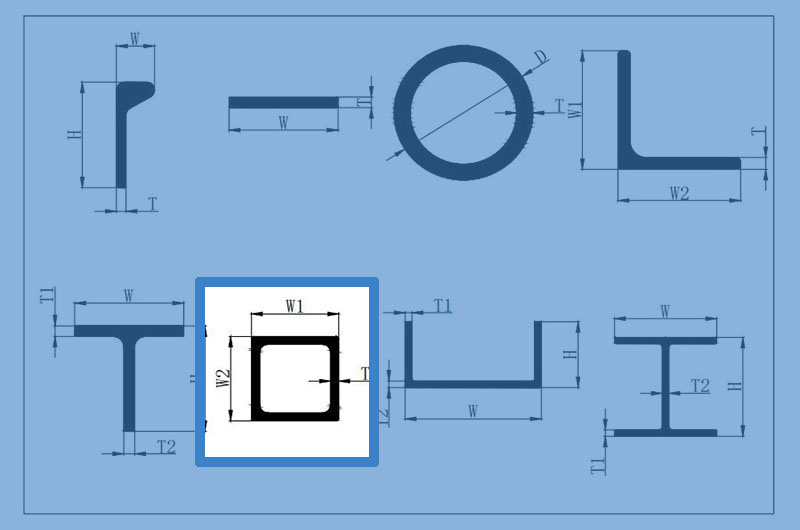

Haomei Marine Grade Aluminum Square Tube Size Specifications

Marine Grade Square Aluminum Tubes come in a variety of sizes, typically ranging from small profiles (e.g., 25x25 mm) to large profiles (e.g., 150x150 mm), with wall thicknesses varying from 1 mm to 10 mm, depending on the application. These tubes are available in various lengths and are usually anodized or coated for additional corrosion protection.

| Width 1 (W1) mm | 25 | 30 | 40 | 50 | 60 | 70 | 75 | 100 | 100 |

| Width 2 (W2) mm | 25 | 30 | 40 | 50 | 50 | 70 | 75 | 100 | 100 |

| Thickness (T) mm | 2.5 | 3 | 4 | 4 | 5 | 4 | 6 | 4 | 6 |

Marine Grade Aluminum Square Tube Alloy Selection

Marine Grade Aluminum Square Tubes are typically made from high-strength aluminum alloys such as 5083, 6061, 6082, and 6063, known for their excellent performance in marine and other harsh environments.

- 5083 alloy is renowned for its excellent seawater corrosion resistance, making it highly favored in marine environments. It has high tensile strength and excellent fatigue resistance, making it suitable for structural applications frequently exposed to harsh marine conditions.

- 6061 is a versatile alloy that combines good mechanical properties with excellent corrosion resistance. It is often used in T6 temper, offering a balanced combination of strength, machinability, and toughness. It is commonly used in structural components requiring a high strength-to-weight ratio.

- 6082, similar to 6061 but with slightly higher strength, is often used in more demanding structural applications. It offers excellent machinability and corrosion resistance, making it suitable for load-bearing applications in marine environments.

- 6063, often referred to as an architectural alloy, is known for its smooth surface finish and good corrosion resistance. Although it has slightly lower strength compared to 6061 and 6082, it is still very effective in marine applications where aesthetics and corrosion resistance are important.

Marine Grade Aluminum Square Tube Applications

Marine Grade Square Aluminum Tubes are used in a wide range of applications, including:

- 1. Frameworks: Providing structural support for decks, hulls, and superstructures.

- 2. Railings: Offering safety and stability in both interior and exterior areas of vessels.

- 3. Supports and Brackets: These tubes are ideal for custom fabrication, easily cut, welded, and formed to meet specific requirements, making them perfect for reinforcing various components of ships or offshore structures.

Marine Grade Aluminum Square Tube Chemical Composition

| Element | 5083 | 6061 | 6082 | 6063 |

| Silicon (Si) | 0.4-0.9% | 0.4-0.8% | 0.7-1.3% | 0.2-0.6% |

| Iron (Fe) | Max 0.4% | Max 0.7% | Max 0.5% | Max 0.35% |

| Copper (Cu) | Max 0.1% | 0.15-0.4% | Max 0.1% | Max 0.1% |

| Manganese (Mn) | 0.4-1.0% | Max 0.15% | 0.4-1.0% | Max 0.1% |

| Magnesium (Mg) | 4.0-4.9% | 0.8-1.2% | 0.6-1.2% | 0.45-0.9% |

| Chromium (Cr) | 0.05-0.25% | 0.04-0.35% | Max 0.25% | Max 0.1% |

| Zinc (Zn) | Max 0.25% | Max 0.25% | Max 0.2% | Max 0.1% |

| Titanium (Ti) | Max 0.15% | Max 0.15% | Max 0.1% | Max 0.1% |

| Other Elements | Max 0.15% (each) | Max 0.15% (each) | Max 0.1% (each) | Max 0.05% (each) |

| Aluminum (Al) | Balance | Balance | Balance | Balance |

What is the difference between 6061 and 6063 aluminum square tube?

- Choose 6061: When higher strength and broader mechanical properties are needed, such as in structural applications and situations requiring the ability to bear larger loads.

- Choose 6063: When superior surface quality, complex profile shapes, and better processing and finishing capabilities are required, such as in architectural decorations, window frames, and door frames.

| Characteristics | 6061 Aluminum Alloy | 6063 Aluminum Alloy |

| Strength | Higher strength: Excellent tensile and yield strength, suitable for structural applications requiring high load-bearing capacity. | Moderate strength: Slightly lower than 6061, but sufficient for most applications. |

| Hardness | Greater hardness: After T6 heat treatment, both hardness and strength are further enhanced. | Good ductility: Easier to process into complex profiles, suitable for applications requiring excellent surface quality. |

6061 Aluminum Square Tube

- Structural applications: Widely used in aerospace, automotive, marine, and other fields that require high strength and good mechanical properties.

- Engineering machinery: Such as bicycle frames, motorcycle frames, and industrial equipment brackets.

6063 Aluminum Square Tube

- Architectural decoration: Commonly used in window frames, door frames, curtain walls, railings, and other architectural structures where superior surface quality and decorative effects are important.

- Furniture manufacturing: Such as display racks, lamp brackets, and more.

- Electronics: Used for making enclosures and frames due to its excellent surface treatment capabilities.

Haomei Marine Grade Aluminum Square Tube Inventory

| Product Name | Specifications (mm) | Brand | Mold No. | Weight per meter (kg/m) | Fixed length(m) | Previous period inventory |

| Square Tube | Square25*2 | 6082-T6 | 25*25*2 | 0.521 | 6 | 463 |

| Square Tube | Square30*2 | 6082-T6 | 30*30*2 | 0.618 | 6 | 170 |

| Square Tube | Square32*3 | 6082-T6 | HZAL-8 | 0.979 | 6 | 454 |

| Square Tube | Square32*32*1.8 | 6082-T6 | HZ32*32*1.8 | 0.61 | 6 | 627 |

| Square Tube | Square40*25*2 | 6082-T6 | YH-HZ-Square40*25*2 | 0.671 | 6 | 501 |

| Square Tube | Square40*3 | 6082-T6 | YH-JG40*40*3 | 1.189 | 6 | 146 |

| Square Tube | Square40*4 | 6082-T6 | YH-HZ-Square40*40*4 | 1.585 | 6 | 98 |

| Square Tube | Square50*30*2 | 6082-T6 | 50*30*2 | 0.834 | 6 | 108 |

| Square Tube | Square50*3 | 6082-T6 | HZAL-9 | 1.632 | 6 | 169 |

| Square Tube | Square50*4 | 6082-T6 | YH-HZ-Square50*50*4 | 2.021 | 6 | 204 |

| Square Tube | Square50*5 | 6082-T6 | YH-HZ50*50*5 | 2.467 | 6 | 158.5 |

| Square Tube | Square50.8*3.2 | 6082-T6 | YH-HZ50.8*50.8*3.2 | 1.657 | 6 | 11.5 |

| Square Tube | Square60*40*4 | 6082-T6 | YH-HZ-Square60*40*4 | 2.002 | 6 | 194 |

| Square Tube | Square60*2.5 | 6082-T6 | 60*60*2.5 | 1.583 | 6 | 17 |

| Square Tube | Square60*60*4 | 6082-T6 | YH-HZ-Square60*60*4 | 2.456 | 6 | 25.5 |

| Square Tube | Square63.5*63.5*6 | 6082-T6 | YH-HZ63.5*63.5*6 | 3.772 | 6 | 20 |

| Square Tube | Square70*70*5 | 6082-T6 | YH-HZ70*70*5 | 3.543 | 6 | 66 |

| Square Tube | Square75*6 | 6082-T6 | 75X75X6 | 4.497 | 6 | 52 |

| Square Tube | Square76.2*3.25 | 6082-T6 | YH-HZ-76.2*76.2*3.25 | 2.58 | 6 | 59 |

| Square Tube | Square80*40*4 | 6082-T6 | YH-HZ-Square80*40*4 | 2.437 | 6 | 121 |

| Square Tube | Square80*50*5 | 6082-T6 | YH-HZ80*50*5 | 3.283 | 6 | 108 |

| Square Tube | Square80*80*5 | 6082-T6 | YH-HZ-Square80*80*5 | 4.089 | 6 | 18 |

| Square Tube | Square80*80*8 | 6082-T6 | YH-HZ80*80*8 | 6.274 | 6 | 46 |

| Square Tube | Square90*90*4 | 6082-T6 | YH-HZ-Square90*90*4 | 3.75 | 6 | 79 |

| Square Tube | Square100*3 | 6082-T6 | HZAL-12 | 3.184 | 6 | 55 |

| Square Tube | Square100*5 | 6082-T6 | HZAL-13 | 5.194 | 6 | 9 |

| Square Tube | Square100*6 | 6082-T6 | HZAL-14 | 6.166 | 6 | 96.5 |

| Square Tube | Square100*50*3 | 6082-T6 | HZAL-11 | 2.375 | 6 | 59 |

| Square Tube | Square100*50*5 | 6082-T6 | YH-HZ-Square100*50*5 | 3.808 | 6 | 38.5 |

| Square Tube | Square100*50*6 | 6082-T6 | YH-HZ-Square100*50*6 | 4.511 | 6 | 82 |

| Square Tube | Square114.3*114.3*3.18 | 6082-T6 | YH-HZ-114.3*114.3*3.18 | 3.852 | 6 | 0 |

| Square Tube | Square120*120*6 | 6082-T6 | YH-HZSquare120*120*6 | 7.449 | 6 | 8 |

| Square Tube | Square120*120*9 | 6082-T6 | YH-HZ-Square120*120*9 | 10.876 | 6 | 45.5 |

| Square Tube | Square150*100*4 | 6082-T6 | YH-HZ150*100*4 | 5.266 | 6 | 11 |

Recommended for you

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

Marine Grade Flat Aluminum refers to flat, rectangular marine aluminum sheets or strips used in structural components, decks, and other flat surfaces on vessels.

-

Marine-grade angular aluminum is used for reinforcing edges, frames, and supports in marine structures with L-shaped or angled aluminum profiles. It is valued for its structural support and corrosion-resistant properties.

-

Marine Grade T-Type Aluminum Profiles

Marine T aluminum is a type of aluminum profile specifically designed for shipbuilding, primarily used for connecting or reinforcing hull parts at a vertical angle.

-

Marine Grade I-Type Aluminum Profiles

Marine-grade I-beam aluminum: An I-beam or H-beam aluminum profile used in marine applications requiring high strength, typically used in the construction of beams, joists, and structural supports.

-

Marine-grade aluminum troughs: A U-shaped or channel profile used in drainage systems, cable management, and structural components in marine environments. They help guide or support materials while resisting corrosion.

-

Marine Grade Aluminum Bulb Flat extrusions

The advantages of Aluminum Bulb Flat Extrusions over other types of extrusions are significant. Compared to traditional extrusions such as angles or flats, bulb flats offer better performance in load distribution and structural reinforcement.