Marine Grade Aluminum Bulb Flat extrusions

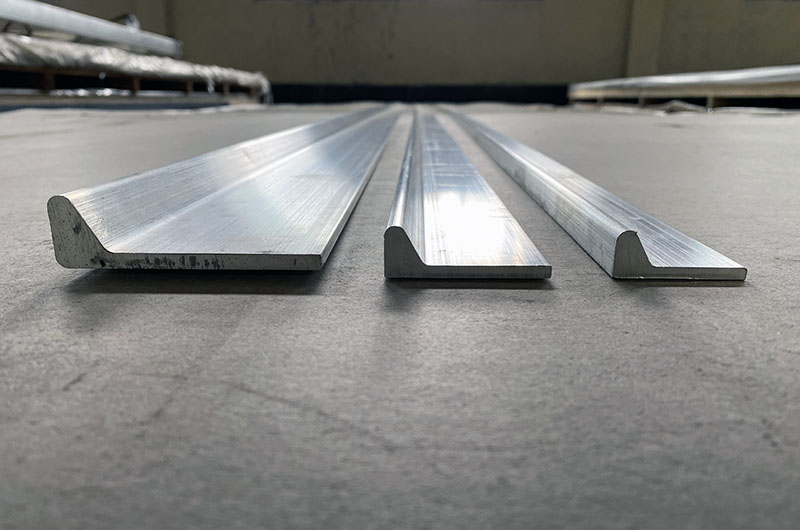

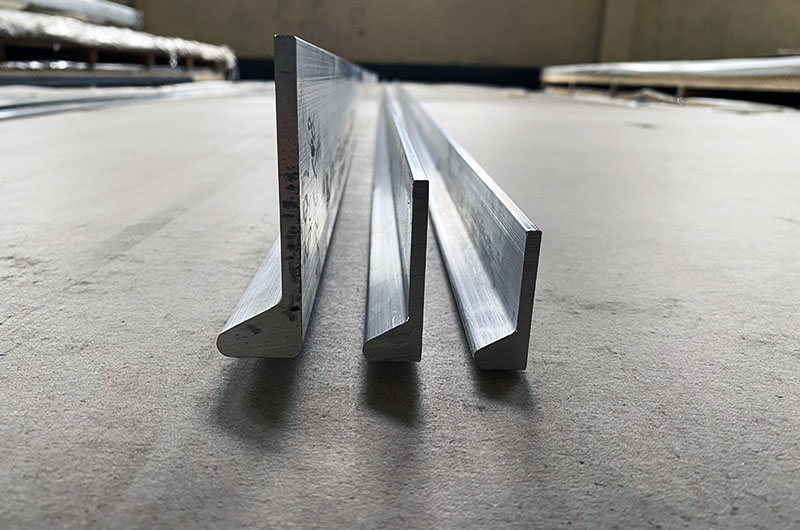

Marine grade aluminum bulb flats, commonly referred to as "bulb flats" or "bulb sections" in shipbuilding, are specially designed aluminum extrusions for marine applications. These extrusions feature a unique bulbous shape at one end, which extends as a "stem" or "web" from the flat profile.

The advantages of Aluminum Bulb Flat Extrusions over other types of extrusions are significant. Compared to traditional extrusions such as angles or flats, bulb flats offer better performance in load distribution and structural reinforcement. The bulbous profile helps distribute loads more evenly and enhances the overall rigidity of the structure in which they are used.

The profile of aluminum bulb flat extrusions extends with a "stem" at one end. Compared to traditional extrusions such as angles or flats, bulb flats have a higher strength-to-weight ratio. As a result, they are widely used in the shipbuilding industry as a superior alternative to stiffeners.

Design Advantages of Aluminum Bulb Flat Extrusions

- 1. Shape and Structure: Bulb flat extrusions have a unique cross-sectional shape, with one side flat and the other side featuring a rounded bulbous extension. This design offers higher strength and rigidity compared to other types of extrusions (angles or flats).

- 2. Strength-to-Weight Ratio: One of the primary advantages of bulb flats is their excellent strength-to-weight ratio. The bulbous extension enhances the structural strength of the extrusion without significantly increasing its weight. This makes bulb flats an excellent choice for applications requiring high strength while maintaining a lighter overall structure.

- 3. Lightweight: One of the main advantages of aluminum in marine applications is its low density, which helps reduce the overall weight of the vessel without compromising strength.

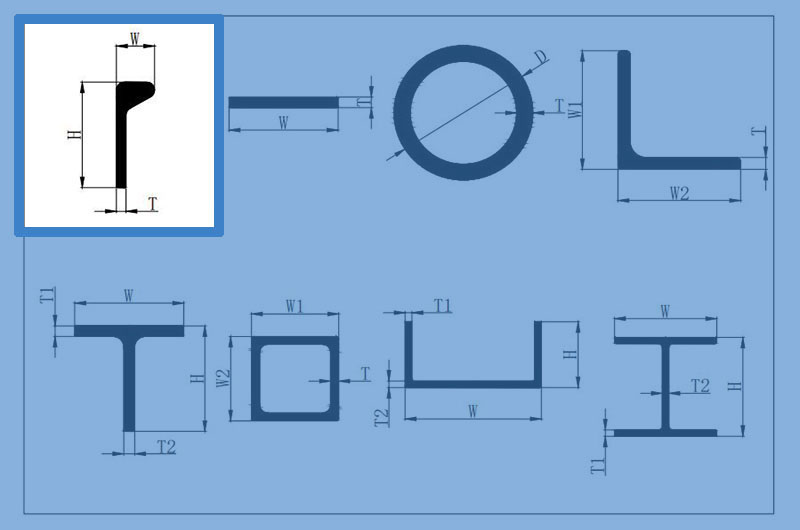

Specifications of Marine Grade Aluminum Bulb Flat Extrusions

Marine grade aluminum bulb flats specifications and measurements

| Height (H) mm | 40 | 50 | 60 | 80 | 90 | 100 | 120 | 140 | 160 |

| Width (W) mm | 14 | 16 | 18 | 18 | 21 | 18.75 | 21 | 18.75 | 21 |

| Thickness (T) mm | 3.5 | 3.5 | 4 | 4.2 | 6 | 4 | 7 | 7 | 7 |

Applications of Aluminum Bulb Flat Extrusions in Shipbuilding

Due to the strong strength-to-weight ratio of bulb flats, they are widely used in the shipbuilding industry. They are typically used as stiffeners or ribs in hulls and deck structures. They provide significant reinforcement and are an ideal choice for enhancing the structural integrity of vessels.

Aluminum Bulb Flat Extrusions are commonly used in the construction of ships and boats, especially in areas requiring robust structural support and effective connections for decks, panels, or other components. Marine-grade bulb flat aluminum is an extruded aluminum shape with a cross-sectional design that allows for secure fastening and connections.

Alloy Materials for Marine Grade Aluminum Bulb Flat Extrusions

Marine-grade aluminum alloys used for bulb flats are typically chosen for their corrosion resistance and durability under harsh marine conditions. Alloys such as 6061 and 6082 are commonly used, each offering a balance of strength, corrosion resistance, and machinability.

6061 Marine Grade Aluminum Bulb Flat Extrusions

Characteristics:

- Strength: 6061 offers good mechanical properties, including high tensile strength and good fatigue resistance. It is known for its high strength-to-weight ratio.

- Corrosion Resistance: Excellent corrosion resistance makes it suitable for marine environments. It performs well under various atmospheric conditions and resists pitting and oxidation.

- Machinability: Easily machined and fabricated, suitable for a variety of applications and custom shapes.

- Heat Treatment: Can be heat-treated to improve its mechanical properties. The T6 condition is commonly used to achieve higher strength.

6082 Marine Grade Aluminum Bulb Flat Extrusions

Characteristics:

- Strength: 6082 is known for its high strength and excellent performance in structural applications. It has higher strength compared to 6061.

- Corrosion Resistance: Very good corrosion resistance, crucial for marine environments. It resists stress corrosion cracking and general corrosion.

- Machinability: Good machinability, though slightly less than 6061. It remains suitable for precision machining and custom fabrication.

- Heat Treatment: Like 6061, 6082 can be heat-treated for higher strength, with T6 temper being a common choice.

The choice between 6061 and 6082 usually depends on specific requirements for strength and machinability, as well as the environmental conditions to which the extrusions will be exposed. Both alloys offer excellent performance and durability in marine environments.

Marine-grade aluminum bulb flats are key components in modern shipbuilding due to their high strength-to-weight ratio and durability. Their unique design provides excellent reinforcement and structural support, making them the preferred choice for various marine applications.

Chemical Composition of Marine Grade Aluminum Bulb Flat Extrusions

- 6061 Aluminum Composition: 6061 is primarily composed of aluminum, magnesium, and silicon. It contains approximately 0.8-1.2% magnesium, 0.4-0.8% silicon, and small amounts of other elements such as copper, chromium, and manganese.

- 6082 Aluminum Composition: 6082 contains aluminum, magnesium, and silicon, similar to 6061 but with slightly higher magnesium content. Typical composition includes 0.7-1.3% magnesium, 0.7-1.3% silicon, and small amounts of manganese and other elements.

Processing and Manufacturing of Aluminum Bulb Flat Extrusions

- Extrusion: Profiles are typically manufactured through an extrusion process, where aluminum billets are forced through a die to form the desired cross-sectional shape. This process allows precise control over the dimensions and consistency of the profiles.

- Surface Treatment: To further enhance corrosion resistance and appearance, profiles can undergo various surface treatments, such as anodizing or powder coating.

Haomei Aluminum Bulb Flat Extrusions Inventory

| Product Name | Specifications (mm) | Brand | Mold No. | Weight per meter (kg/m) | Fixed length(m) | Previous period inventory |

| Bulb Flat Aluminum | BF40*14*3.5 | 6082-T6 | YH-QC-HZ-34 | 0.592 | 12.2 | 4 |

| Bulb Flat Aluminum | BF40*14*3.5 | 6082-T6 | YH-QC-HZ-34 | 0.592 | 6 | 518 |

| Bulb Flat Aluminum | BF40*15*4 | 6082-T6 | YH-HZ-31 | 0.682 | 6 | 528 |

| Bulb Flat Aluminum | BF45*15*4 | 6082-T6 | YH-HZ-BF45*15*4 | 0.737 | 6 | 75 |

| Bulb Flat Aluminum | BF50*15*3 | 6082-T6 | YH-HZ-BF50*15*3 | 0.791 | 6 | 78 |

| Bulb Flat Aluminum | BF50*16*3.5 | 6082-T6 | YH-QC-HZ-35 | 0.749 | 12.2 | 72 |

| Bulb Flat Aluminum | BF50*16*3.5 | 6082-T6 | YH-QC-HZ-35 | 0.749 | 6 | 96 |

| Bulb Flat Aluminum | BF50*16*4 | 6082-T6 | YH-QC-HZ-27 | 0.824 | 6 | 582 |

| Bulb Flat Aluminum | BF50*16*5 | 6082-T6 | YH-HZ-BF50*16*5 | 0.906 | 6 | 55 |

| Bulb Flat Aluminum | BF60*12*3.3 | 6082-T6 | YH-HZ-BF60*12*3.3 | 0.736 | 6 | 100 |

| Bulb Flat Aluminum | BF60*15*3 | 6082-T6 | MB-179 | 0.872 | 6 | 49 |

| Bulb Flat Aluminum | BP60*15*5(Square head) | 6082-T6 | YH-HZ-BP60*15*5 | 1.108 | 6 | 0 |

| Bulb Flat Aluminum | BF60*18*4 | 6082-T6 | YH-HZ-33 | 1.003 | 12.2 | 34 |

| Bulb Flat Aluminum | BF60*18*4 | 6082-T6 | YH-HZ-33 | 1.003 | 6 | 130.5 |

| Bulb Flat Aluminum | BF60*19*5 | 6082-T6 | HZAL-01 | 1.173 | 6 | 468 |

| Bulb Flat Aluminum | BF60*25*5 | 6082-T6 | YH-HZ-BF60*25*5 | 1.334 | 6 | 0 |

| Bulb Flat Aluminum | BF65*18.5*3.5 | 6082-T6 | YH-HZ-BF65*18.5*3.5 | 1.156 | 6 | 60 |

| Bulb Flat Aluminum | BF70*16*4 | 6082-T6 | YH-HZ-BF70*16*4 | 1.019 | 6 | 84 |

| Bulb Flat Aluminum | BF76.2*22*5.6 | 6082-T6 | YH-HZ-BF76.2*22*5.6 | 1.634 | 6 | 20 |

| Bulb Flat Aluminum | BF80*16.6*3.7 | 6082-T6 | YH-HZ-BF80*16.6*3.7 | 1.146 | 6 | 136 |

| Bulb Flat Aluminum | BF80*22*4 | 6082-T6 | YH-HZ-BF80*22*4 | 1.386 | 6 | 60 |

| Bulb Flat Aluminum | BF80*22*5 | 6082-T6 | YH-QC-HZ-36 | 1.588 | 12.2 | 29 |

| Bulb Flat Aluminum | BF80*22*5 | 6082-T6 | YH-QC-HZ-36 | 1.588 | 6 | 73.5 |

| Bulb Flat Aluminum | BF80*22*7 | 6082-T6 | YH-HZ-BF80*22*7 | 1.948 | 6 | 140 |

| Bulb Flat Aluminum | BF85*20*5 | 6082-T6 | YH-HZ-BF85*20*5 | 1.577 | 6 | 147 |

| Bulb Flat Aluminum | BP85*20*5(Square head) | 6082-T6 | YH-HZ-BP85*20*5 | 1.761 | 6 | 2 |

| Bulb Flat Aluminum | BF90*18.75*4 | 6082-T6 | BF90*18.75*4 | 1.409 | 12 | 31 |

| Bulb Flat Aluminum | BF98.7*19.05*5.35 | 6082-T6 | YH-HZ-BF98.7*19.05*5.35 | 1.859 | 6 | 176 |

| Bulb Flat Aluminum | BF100*21*4.2 | 6082-T6 | YH-HZ-BF100*21*4.2 | 1.641 | 6 | 78 |

| Bulb Flat Aluminum | BF105*18.75*4 | 6082-T6 | BF105*18.75*4 | 1.573 | 12 | 45 |

| Bulb Flat Aluminum | BF105*18.75*4 | 6082-T6 | BF105*18.75*4 | 1.573 | 6 | 148 |

| Bulb Flat Aluminum | BF120*25*7 | 6082-T6 | YH-HZ-BF120*25*7 | 2.838 | 6 | 31 |

| Bulb Flat Aluminum | BF120*25*8 | 6082-T6 | YH-HZ-HP120*25*8 | 3.12 | 6 | 54 |

| Bulb Flat Aluminum | BF140*27*7 | 6082-T6 | YH-HZ-BF140*27*7 | 3.313 | 6 | 17 |

| Bulb Flat Aluminum | BF160*29*7 | 6082-T6 | YH-HZ-BF160*29*7 | 3.794 | 6 | 50 |

| Ball Head Aluminum | IP50(24*3.5) | 6082-T6 | YH-HZ-IP50*24*3.5 | 1.008 | 6 | 130 |

| Ball Head Aluminum | IP50(25*4) | 6082-T6 | HZAL-32 | 0.978 | 6 | 231 |

| Ball Head Aluminum | IP50(30*4) | 6082-T6 | HZAL-21 | 0.967 | 8.1 | 41 |

| Ball Head Aluminum | 125x4Ball head(25/33) | 6082-T6 | YH-MB-155 | 2.515 | 6 | 4 |

| Ball Head Aluminum | IP60(28*4) | 6082-T6 | YH-HZ-IP60*28*4 | 1.363 | 6 | 40 |

| Ball Head Aluminum | IP60(30*4) | 6082-T6 | HZAL-19 | 1.262 | 6 | 289 |

| Ball Head Aluminum | IP70(33*4) | 6082-T6 | YH-HZ-IP70*33*4 | 1.47 | 6 | 54 |

| Ball Head Aluminum | IP80(36*5) | 6082-T6 | HZAL-20 | 1.92 | 6 | 132 |

| Ball Head Aluminum | IP90(40*4.5) | 6082-T6 | YH-HZ-IP90*40*4.5 | 2.099 | 6 | 17 |

| Ball Head Aluminum | IT60*40*4/4 | 6082-T6 | YH-HZ-IT60*40*4/4 | 1.432 | 6 | 233 |

| Ball Head Aluminum | IT70*40*4/4 | 6082-T6 | YH-HZ-IT70*40*4/4 | 1.531 | 6 | 226 |

| Ball Head Aluminum | IT80*40*4.5/4 | 6082-T6 | YH-HZ-IT80*40*4.5*4 | 1.752 | 6 | 110 |

| Ball Head Aluminum | IT120*6.5*50*4 | 6082-T6 | YH-HZ-IT120*6.5*50*4 | 3.147 | 6 | 83 |

| Ball Head Aluminum | IT120*50*6.5/3 | 6082-T6 | HZAL-22 | 3.017 | 6 | 63 |

| Ball Head Aluminum | IT140*50*7.5/4 | 6082-T6 | HZAL-23 | 3.831 | 6 | 28 |

Recommended for you

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

Marine Grade Flat Aluminum refers to flat, rectangular marine aluminum sheets or strips used in structural components, decks, and other flat surfaces on vessels.

-

Marine-grade angular aluminum is used for reinforcing edges, frames, and supports in marine structures with L-shaped or angled aluminum profiles. It is valued for its structural support and corrosion-resistant properties.

-

Marine Grade T-Type Aluminum Profiles

Marine T aluminum is a type of aluminum profile specifically designed for shipbuilding, primarily used for connecting or reinforcing hull parts at a vertical angle.

-

Marine Grade I-Type Aluminum Profiles

Marine-grade I-beam aluminum: An I-beam or H-beam aluminum profile used in marine applications requiring high strength, typically used in the construction of beams, joists, and structural supports.

-

Marine Grade Aluminum Square Tube

Marine Grade Square Tube: A type of hollow square aluminum profile used in frameworks, railings, and other structural applications where both strength and corrosion resistance are critical.

-

Marine-grade aluminum troughs: A U-shaped or channel profile used in drainage systems, cable management, and structural components in marine environments. They help guide or support materials while resisting corrosion.