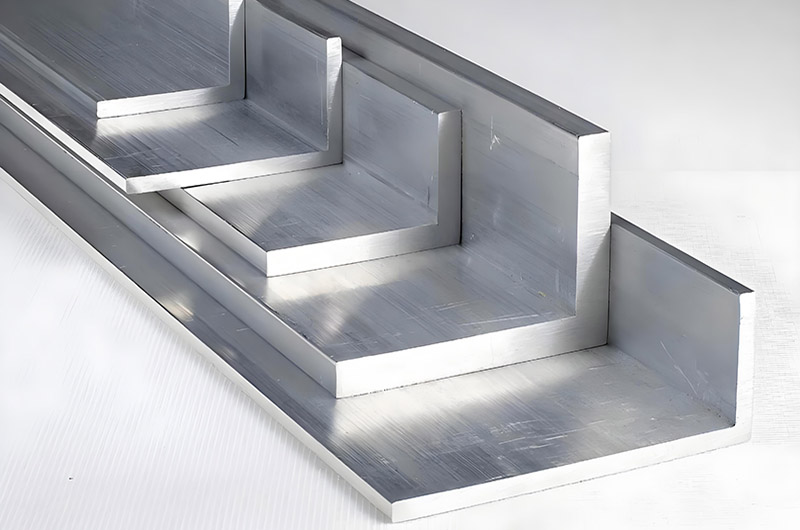

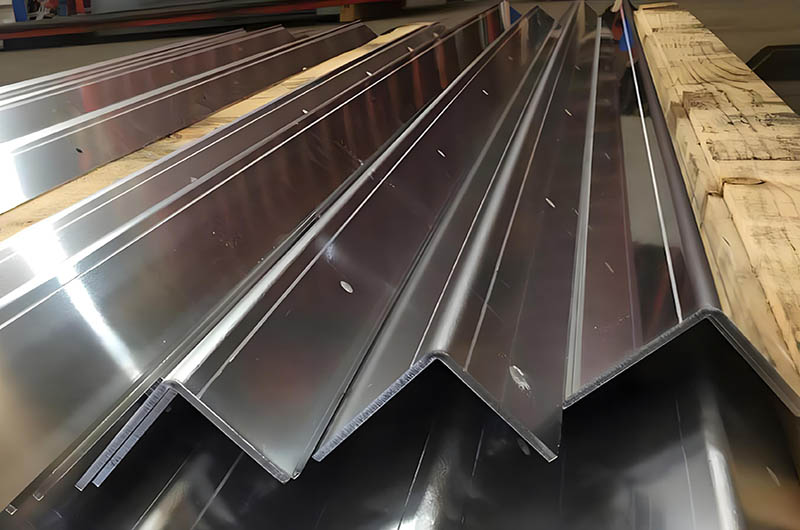

5086 Aluminum Angle

5086 aluminum angle is an L-shaped structural profile made from 5086 aluminum alloy, featuring medium strength, excellent corrosion resistance, and weldability.

5086 aluminum angle is a high-strength marine-grade alloy primarily composed of aluminum and magnesium. This alloy is known for its excellent corrosion resistance, especially in seawater environments, and is commonly used in ship hulls, pressure vessels, and tanks, among other applications.

Haomei Aluminum, as a leading supplier of 5086 aluminum alloy angles, provides a full range of sizes in 5086-H111 structural angles, suitable for marine ladders, pressure vessels, and transportation equipment. The products are renowned for their excellent seawater corrosion resistance, high weldability, and medium-high strength. We support customized cutting and pre-processing services to ensure fast delivery and project efficiency. With certifications such as ASTM and MIL, we guarantee quality and global export availability.

5086 Aluminum Angle Characteristics

| Characteristics | Description |

| Corrosion Resistance | Excellent resistance to saltwater and acidic environments, making it an ideal choice for marine applications such as ship hulls, ladders, and offshore structures. It is more resistant to stress corrosion cracking than many other aluminum alloys. |

| Common Tempers | Includes H111 (strain-hardened and stabilized), H32, and H116 (optimized for marine applications). |

| Weldability | Can be easily welded using TIG, MIG, or friction stir welding. Even in the hardened tempers, the welded joints retain approximately 90% of their strength. |

| Formability and Machinability | Good cold working characteristics, especially in the O temper (annealed state). With proper lubrication, it can be processed in hardened tempers (such as H34, H36). |

5086 Aluminum Angle Chemical Composition

5086 aluminum angle is a high-strength, non-heat-treatable alloy primarily composed of aluminum (95.4%) and magnesium (3.5-4.5%), with additions of manganese, chromium, and other elements. The alloy is strengthened by strain hardening (cold working) and is widely recognized for its excellent corrosion resistance (especially in marine environments) and versatility in structural and industrial applications.

The typical composition of 5086 aluminum alloy is as follows:

- Magnesium (Mg): 3.5–4.5%

- Manganese (Mn): 0.2–0.7%

- Chromium (Cr): 0.05–0.25%

- Copper (Cu): ≤0.1%

- Iron (Fe): ≤0.5%

- Silicon (Si): ≤0.4%

- Zinc (Zn): ≤0.25%

- Titanium (Ti): ≤0.15%

- Aluminum (Al): Remainder

5086 Aluminum Angle Mechanical Properties

The mechanical properties of 5086 aluminum vary by temper:

- Tensile Strength: 275–350 MPa

- Yield Strength: 125 MPa (minimum)

- Hardness (Brinell): 75 HB

- Elongation: ≥12%

These properties make it suitable for structural applications requiring high strength and durability.

5086 Aluminum Angle Physical Properties

Density: 0.096 lb/in³ (2.66 g/cm³); Melting Point: 1, 085–1, 185°F (585–641°C).

5086 Aluminum Angle Sizes and Specifications

| Specification | Description |

| Equal Leg Angle | Size range: 0.5 inches × 0.5 inches × 1/8 inch to 8 inches × 8 inches × 1 inch; Weight range: 0.131 lbs/ft to 17.667 lbs/ft. |

| Unequal Leg Angle | Size range: 2 inches × 1 inch × 1/8 inch or 3 inches × 2.5 inches × 1/4 inch; Radii (R1 and R2) variable to ensure structural integrity. |

| Standards | ASTM B211 (Bar), B221 (Extrusions), ASME SB211, and Military Specifications (e.g., MIL C-26094). |

| Available Sizes | Common sizes: 1 inch × 1 inch × 1/8 inch, 2 inches × 2 inches × 1/4 inch, and 3 inches × 3 inches × 1/4 inch. |

| Tempers | Available in H111 and H32 tempers to meet various application requirements. |

5086 Aluminum Angle Applications

Applications of 5086 Aluminum Angle in the Marine Field

Shipbuilding: Hulls, yacht components, gangways, and offshore oil drilling platforms.

Shipbuilding and Marine Engineering: Used in hull frames, deck supports, and other structural components, resistant to seawater corrosion and stable performance after welding.

- Ship and yacht hulls

- Pressure vessels and storage tanks

- Cryogenic equipment

- Offshore structures

- Transport equipment

- Armor plates

What Other Fields is 5086 Aluminum Angle Used In?

- Transport: Armored vehicles, rail vehicles, and trailers.

- Structures: Pressure vessels, transmission towers, building frames, and scaffolding.

- Industry: Cryogenic equipment, drilling platforms, and uncured pressure vessels.

Used as the body framework or connection components for automobiles and rail vehicles, reducing weight while meeting strength requirements.

5086 Aluminum Angle Manufacturing and Welding

5086 aluminum alloy is not heat treatable and can be strengthened by cold working processes. It has excellent weldability, maintaining most of its mechanical strength after welding. Common welding methods include MIG and TIG welding, and friction stir welding can also be used.

5086 Aluminum Angle Processing

- Weldability: Supports various processes such as TIG welding, laser welding, etc., with high weld strength and resistance to cracking.

- Weather Resistance: The surface can be anodized to enhance protection, maintaining stability even after prolonged exposure to humid or salt-spray environments.

- Customizability: Custom aluminum angles with different thicknesses and lengths can be provided according to requirements, adapting to complex structural designs.

Manufacturing and Testing

- Processing: Extruded into angle sections, typically pre-cut or welded into modular components for assembly.

- Testing: Includes hardness, ultrasonic, and third-party inspections to ensure compliance with ASTM/ASME standards.

Advantages and Considerations of 5086 Aluminum Angle

Advantages:

- Lightweight and durable, with a high strength-to-weight ratio.

- More cost-effective than stainless steel in harsh environments.

Considerations:

- Avoid prolonged exposure to high temperatures (>212°F) to prevent softening.

- Use compatible fasteners to prevent electrochemical corrosion in marine environments.

Recommended for you

-

As a professional aluminum material manufacturer, we provide 5086 H111 aluminum alloy angles, combining high strength and excellent corrosion resistance, especially suitable for the marine, offshore engineering, and industrial structural fields.

Other content readers are interested in

-

5086 marine grade aluminium checkered tread plate sheet

5086 marine grade aluminum checkered tread plate sheet has higher strength and corrosion resistance than 5052 and 5083 plates, making it ideal for many marine and marine applications.

-

5059 5086 Marine Grade Aluminum Bars

Marine-grade aluminum rods such as 5059 and 5086 combine corrosion resistance, strength and lightweight properties, making them an indispensable material in a variety of marine applications where durability and reliability are important.

-

5086 Marine Grade Aluminum Plate Sheet

Marine-grade aluminum alloy 5086 combines corrosion resistance, rust resistance, strength, weldability, formability and resistance to environmental factors, making it ideal for underwater components of ship hulls and other marine applications.

-

As a direct manufacturer of 5086 Aluminum Sheet, we offer marine-grade aluminum plates that meet ASTM B209/EN 485 standards, featuring excellent seawater corrosion resistance and weldability.

-

As a professional aluminum plate manufacturer, we offer high-performance 5086 H116 aluminum alloy plates in a variety of specifications to meet the lightweight and industrial requirements of hulls.

-

As a leading manufacturer of aluminum alloys, we specialize in supplying 5086 H32 aluminum plate, ideal for harsh marine, industrial, and structural applications.

-

Our company specializes in the production of 5086 H111 medium-thick aluminum plates, with a finely polished surface and strong resistance to seawater corrosion. We offer customized cutting and welding services, and provide international certifications such as BV/DNV/ABS, with quick response to custom needs.

-

As a professional manufacturer of 5086 aluminum tubes, we offer seamless cold drawn aluminum tubes that comply with ASTM B210/B221 standards, with material strengthened by magnesium alloys, combining high strength and excellent seawater corrosion resistance.

-

5086 Aluminum Round Tubes and Pipes

As a professional aluminum alloy tube manufacturer, we offer 5086 aluminum alloy seamless round tubes, produced using high-precision cold drawing processes, conforming to international standards such as ASTM B210.

-

As a professional aluminum material manufacturer, we offer high-quality 5086 aluminum alloy square tubes, specifically designed for ships, marine engineering, and high-corrosion environments.

-

5086 Aluminum Drawn Seamless Pipe

As a leading manufacturer of precision aluminum products, we specialize in producing 5086 Aluminum Drawn Seamless Pipes designed for harsh environments.

-

5086 aluminum alloy round bars achieve high strength through cold mechanical processing, offering excellent seawater corrosion resistance and weldability. They are specifically designed for shipbuilding, marine engineering, and transportation equipment.

-

Professional production of 5086 aluminum flat bars, complete product specifications, direct sale from the manufacturer, favorable prices, strict quality control to ensure compliance with ASTM, EN, and other international standards.

-

As a professional aluminum alloy material manufacturer, we offer 5086 H111 aluminum alloy round bars, specially designed for harsh environments, suitable for shipbuilding, marine engineering, and industrial structural fields.

-

As a professional 5086 H32 pipe manufacturer, we provide high-performance, seawater corrosion-resistant customized pipe products, combining excellent strength and lightweight properties. Non-standard size processing is supported, and products are tested according to ISO certification and ASTM/EN standards.

Recommended for you

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

Marine Grade Flat Aluminum refers to flat, rectangular marine aluminum sheets or strips used in structural components, decks, and other flat surfaces on vessels.

-

Marine-grade angular aluminum is used for reinforcing edges, frames, and supports in marine structures with L-shaped or angled aluminum profiles. It is valued for its structural support and corrosion-resistant properties.

-

Marine Grade T-Type Aluminum Profiles

Marine T aluminum is a type of aluminum profile specifically designed for shipbuilding, primarily used for connecting or reinforcing hull parts at a vertical angle.

-

Marine Grade I-Type Aluminum Profiles

Marine-grade I-beam aluminum: An I-beam or H-beam aluminum profile used in marine applications requiring high strength, typically used in the construction of beams, joists, and structural supports.

-

Marine Grade Aluminum Square Tube

Marine Grade Square Tube: A type of hollow square aluminum profile used in frameworks, railings, and other structural applications where both strength and corrosion resistance are critical.

-

Marine-grade aluminum troughs: A U-shaped or channel profile used in drainage systems, cable management, and structural components in marine environments. They help guide or support materials while resisting corrosion.

-

Marine Grade Aluminum Bulb Flat extrusions

The advantages of Aluminum Bulb Flat Extrusions over other types of extrusions are significant. Compared to traditional extrusions such as angles or flats, bulb flats offer better performance in load distribution and structural reinforcement.

More content of interest to readers

What is the difference between 5086 and 6061 aluminum? 5086 H32 vs H116 What is 5086 grade aluminum? 5086 Aluminum vs 5052 5086 Aluminum vs. 5456 Aluminum 5086 and 5083 Aluminum Materials in Shipbuilding

You might be interested in: Marine Aluminum 5086