5083 Aluminum profile for hull keel

Aluminum has long been hailed as a revolutionary material in maritime engineering, offering a unique combination of strength, durability and lightweight properties. Among various aluminum alloys, 5083 is the material of choice for building hull keels due to its excellent properties.

The hull keel, often just called the keel, is the structural component along the centerline of the bottom of the hull. The hull keel plays a vital role in the stable navigation of the ship.

- 1. Stability and capsizing resistance: The main function of the keel is to provide stability to the ship and prevent it from capsizing or excessive rolling in rough seas. By lowering the center of gravity, the keel counteracts the forces of wind and waves, helping the ship maintain an upright position.

- 2. Directional stability and maneuverability: The keel also plays a vital role in providing directional stability and controlling the ship's course. Its streamlined shape helps reduce lateral drift, allowing the vessel to maintain a straight trajectory and promote smoother maneuvering.

- 3. Structural support: In addition to its hydrodynamic function, the keel also acts as a structural support for the hull, evenly distributing the weight of the ship and providing support for the entire hull structure. It helps absorb and disperse the forces encountered during navigation, thereby reducing stress on other parts of the ship.

The lightweight properties of 5083 aluminum help reduce the overall weight of a vessel’s structure, thereby improving fuel efficiency, speed and maneuverability. The weight reduction also helps optimize the ship's payload capacity without compromising structural integrity.

Why choose 5083 aluminum for the hull keel?

Choosing the correct hull keel construction material is critical to ensuring the safety, performance and longevity of your vessel. Of the various materials available, 5083 aluminum alloy is often the first choice for hull keel structures due to its superior properties.

- 1. High Strength: 5083 aluminum has an impressive strength-to-weight ratio, providing the necessary structural integrity without adding excessive weight to the container. This strength ensures that the keel can withstand the stresses encountered during navigation, including wave impact and grounding.

- 2. Corrosion resistance: One of the most significant advantages of 5083 aluminum is its excellent corrosion resistance, especially in marine environments. The alloy forms a protective oxide layer on its surface that acts as a barrier against corrosion caused by salt water exposure, ensuring the longevity of the keel and minimizing maintenance requirements.

- 3. Lightweight: Aluminum (including 5083 alloy) is much lighter than many other materials commonly used in hull keel construction, such as steel. The lightweight properties of 5083 aluminum help reduce the overall weight of the vessel, thereby improving fuel efficiency, speed and maneuverability.

- 4. Durability: 5083 aluminum offers exceptional durability and can withstand harsh marine environments, including exposure to salt water, UV radiation, and harsh weather conditions. Its durability ensures that the keel maintains its structural integrity over time, reducing the risk of fatigue and structural failure.

- 5. Ease of fabrication: Aluminum alloys such as 5083 are highly formable and weldable, making them ideal for complex geometries and custom designs. This easy-to-manufacture approach allows for efficient fabrication of keel profiles customized to specific vessel requirements, enhancing design flexibility and customization options.

In summary, choosing 5083 aluminum for hull keel structure offers a combination of strength, corrosion resistance, lightweight, durability and ease of fabrication, making it an ideal material for ensuring the safety, performance and longevity of marine vessels.

Hull keel 5083 aluminum profile composition and alloying elements

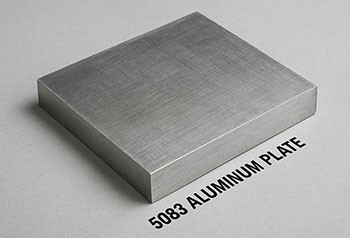

The main components of 5083 aluminum alloy are aluminum, magnesium, manganese and chromium. Precise composition is crucial to achieve the required mechanical properties and corrosion resistance.

- Aluminum (Al): Primary component that provides base strength and corrosion resistance.

- Magnesium (Mg): Adds strength and corrosion resistance to alloys.

- Manganese (Mn): Improves the grain structure and strength of alloys.

- Chromium (Cr): Contributes to the alloy's resistance to corrosion and oxidation.

Hull keel 5083 aluminum profile mechanical properties

5083 aluminum has excellent mechanical properties and is suitable for hull keel structures. Key attributes include:

- Tensile Strength: Typically 275 to 350 MPa, depending on temper condition.

- Yield strength: generally around 125~250MPa.

- Elongation: Typically between 10% and 25%.

- Hardness: Varies depending on temper, values typically range from 75 to 120 HB.

Hull keel 5083 aluminum profile corrosion resistance

One of the most significant advantages of 5083 aluminum is its excellent corrosion resistance, especially in marine environments. The alloy forms a protective oxide layer on the surface that acts as a barrier against corrosion, even in salt water conditions.

Advantages and Benefits of 5083 Aluminum Profile for hull keel

1. Strength to weight ratio

5083 aluminum has an excellent strength-to-weight ratio that exceeds many other materials commonly used in hull keel construction. This results in lighter ships with comparable or even greater strength and durability, resulting in improved performance and efficiency.

2. Durability and longevity

The corrosion-resistant properties of 5083 aluminum ensure the long-term durability of the hull keel, even in harsh marine environments. This reduces maintenance requirements and extends the life of the vessel, resulting in significant cost savings over time.

3. Cost-effectiveness

Despite its advanced properties, 5083 aluminum profiles are still cost-effective compared to alternative materials such as steel. Reduced maintenance costs, extended service life and improved performance contribute to overall cost savings over the life of the vessel.

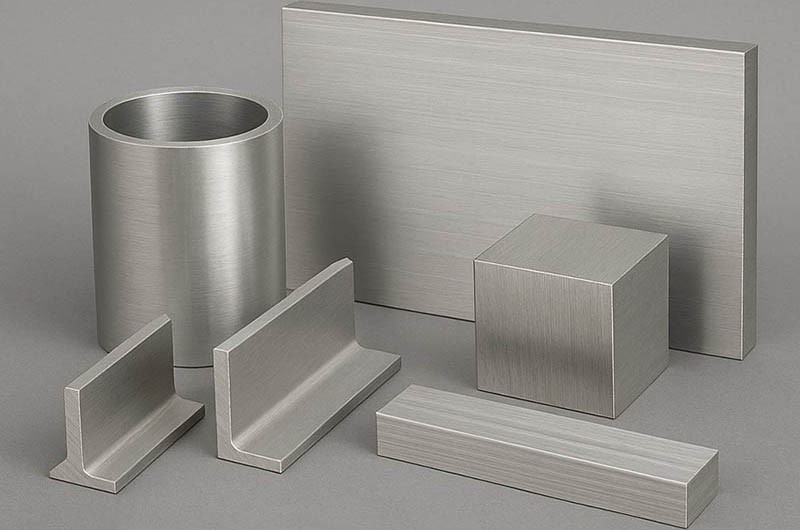

Hull keel 5083 aluminum profile applications

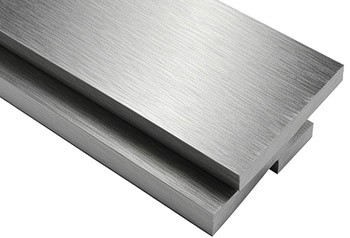

5083 aluminum profiles are used in various structural components of the hull keel, including keel beams, keel struts and keel plates. These components provide strength and rigidity to the hull, ensuring stability and structural integrity.

Hull keel 5083 aluminum profile manufacturing process

1. Alloy preparation

The manufacturing process begins with the preparation of the alloy, which includes the melting and alloying of the raw materials. Precise control of alloy composition is critical to ensure the desired mechanical properties are achieved.

2. Extrusion process

Extrusion is the primary method for producing 5083 aluminum profiles for hull keel structures. The process involves forcing heated aluminum alloy through a forming die to create the desired profile. Factors such as mold design, temperature control and extrusion speed play a crucial role in achieving the desired profile dimensions and mechanical properties.

3. Heat treatment

After extrusion, the profile is heat treated to further enhance its mechanical properties. This typically involves a solution heat treatment to dissolve the alloying elements, followed by a quenching and aging process to precipitate the desired strengthening phase.

Marine aluminum products you may be interested in

-

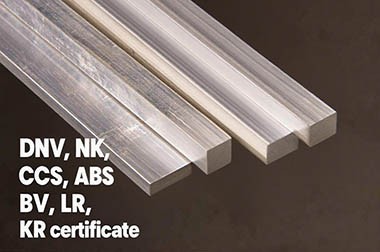

5083 5383 O H112 Marine Grade Aluminum Bars

5083 5383 O H112 Marine Grade Aluminum Bars are certified by CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and their quality fully complies with world marine grade standards.

-

5083 Marine Grade Aluminum Pipe Tube

5083 Marine Grade Aluminum Pipe is commonly used in various marine applications such as shipbuilding, ship construction, offshore platforms and marine structures.

-

5083 marine grade aluminium checkered tread plate sheet

5083 pattern aluminum plate is widely used in decoration, shipbuilding and construction fields. Aluminum pattern plate has good forming, drilling and welding capabilities, is easy to manufacture, and its raised diamond lug pattern provides good slip resistance.

-

5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum is an aluminum alloy specifically designed for use in marine environments. It is known for its excellent corrosion resistance and high strength, making it ideal for applications such as shipbuilding, hulls, offshore structures and other marine components.

-

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications.

-

Our company offers 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV), featuring excellent corrosion resistance, weldability, and medium strength. They are widely used in ship decks, hull outer plates, LNG storage tanks, and other fields.

-

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

-

With 20 years of experience in marine-grade aluminum production, our products are all certified by classification societies (such as CCS, DNV, etc.), and we offer customized solutions upon request.

-

5083 aluminum alloy flat bar is a high-performance aluminum material with magnesium as the main alloying element, specially designed for harsh environments. It is widely used in shipbuilding, pressure vessels, rail transportation, and cryogenic engineering.

-

Specialized in producing 5083 aluminum bars, offering multiple tempers such as H112 and O, supporting custom machining with outer diameters ranging from Φ15mm to 450mm. Ample stock and fast delivery.

-

5083 aluminum round bar is a high-performance corrosion-resistant alloy primarily used in harsh environments, especially marine applications. This non-heat-treatable alloy achieves its mechanical properties through strain hardening. Common tempers include H111, H116, and H321.

-

We specialize in the production of 5083 aluminum square tubes, supporting customization of outer diameter (10–2500mm), wall thickness (0.4–100mm), and length (5–2000mm). Certified by ISO, SGS, BV, and other international standards to ensure stable and reliable mechanical properties.

-

Specializing in the production of 5083 H131 aluminum plates, we offer customized production with thicknesses from 0.2 to 350mm and widths from 30 to 2600mm. Global export supported, original factory warranty, and 30-day delivery.

-

5083-H32 aluminum plate plays a key role in shipbuilding due to its excellent performance. Whether used for structural components in large vessels or critical parts of high-performance speedboats, it delivers reliable performance and long-term durability.

-

5083 O aluminum is a special state aluminum material based on 5083 aluminum alloy, formed through an annealing process.

-

5083-H22 is an aluminum-magnesium alloy plate, belonging to the 5xxx series of non-heat-treatable aluminum alloys.

-

5083 H34 is a strain-hardened and stabilized aluminum alloy in the 5000 series, known for its high strength, excellent corrosion resistance, and good weldability.

-

5083 5383 Marine Grade Aluminium Hex Bar

The 5083 and 5383 aluminum hex bars produced by Haomei comply with multiple international and industry standards to ensure product quality and performance meet global application requirements.

-

5083 5383 O H112 Marine Aluminum Square Bar

Haomei Aluminum is capable of producing marine-grade 5083 and 5383 aluminum square bars in O and H112 tempers, certified by major international classification societies including DNV, NK, CCS, ABS, BV, LR, and KR.

Popular searches for marine aluminum materials

- Marine grade aluminum plates

- Marine grade aluminum checker plate

- Marine grade aluminum bar

- Marine grade aluminum honeycomb plate

- Marine grade aluminum foam sheet plate

- Marine grade ribbed stiffener aluminum plate sheet

- Marine grade aluminum welding wire

- Marine grade aluminum pipe tube

- Marine Aluminum Profiles

- Aluminium Flanges

- Aluminum Tees

- Aluminum Elbow

- Aluminum Pipe Fitting Caps

- Aluminum Reducer

- Aluminum/steel clad plate

You might be interested in: Marine Grade Aluminum 5083 5 Series Marine Aluminum Aluminum for Shipbuilding Aluminum for Boat 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum