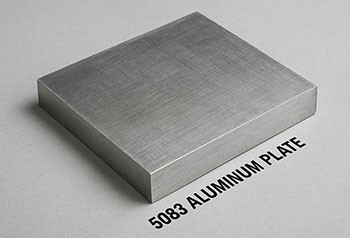

What are the common temper of 5083 aluminum plates for ships?

Last Updated :

Common states of 5083 aluminum plates include H111, H112, H116 and H321. Each state of aluminum plates has its own specific performance characteristics to meet different application requirements.

When it comes to marine aluminum plates, 5083 aluminum plates are undoubtedly the most commonly mentioned one. As a 5-series aluminum-magnesium alloy, it is widely used in the manufacture of ships and yachts, especially in medium and thick aluminum plates. Common states include H111, H112, H116 and H321. Each state of aluminum plates has its own specific performance characteristics to meet different application requirements.

- H111 aluminum plate is moderately work-hardened after annealing, but its strength is not as good as that of H112 state products.

- H112 state is suitable for free processing of hot-rolled plates.

- H116 state is suitable for 5 series alloys with high magnesium content.

- H321 state provides optimal strength and stability.

Haomei Aluminum's 5083 h111 aluminum plate has stable performance, adopts strict quality and environmental management systems, and has passed CCS, DNV, NK, CCS, ABS, BV, LR, KR certification.

Marine aluminum plate 5083 h111

5083 H111 aluminum plate is moderately annealed and work-hardened. It provides balanced performance in strength and corrosion resistance, suitable for applications where strength requirements are not particularly high but still require certain corrosion resistance. For example, aluminum plates in this state are often used in hull structures, cabins and other parts that have certain requirements for corrosion but do not bear extreme loads.

Marine aluminum plate 5083 h112

5083 H112 aluminum plate has relatively high strength and is suitable for applications requiring higher strength. It is usually used in the free processing state of hot rolled plate, showing good processing performance and high strength. Suitable for parts requiring higher structural strength, such as the main structure of the hull, frames and load-bearing parts.

Marine aluminum plate 5083 h116

5083 H116 aluminum plate provides excellent corrosion resistance and is particularly suitable for use in extreme environments. This state of aluminum plate is made of 5 series alloy containing ≥4.0% magnesium. The high magnesium content makes it show excellent corrosion resistance in harsh environments and is often used in applications in marine environments, such as hull shells and parts below the waterline.

Marine aluminum plate 5083 h321

5083 H321 aluminum plate has higher strength and corrosion resistance and is suitable for structural parts with high strength requirements. Aluminum plates in this state undergo rigorous work-hardening treatment during the production process, ensuring the stability and durability of their performance, making them suitable for use in demanding engineering applications such as high-load structural parts, heavy hulls, etc.

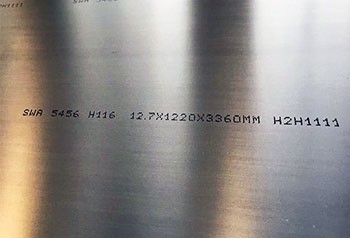

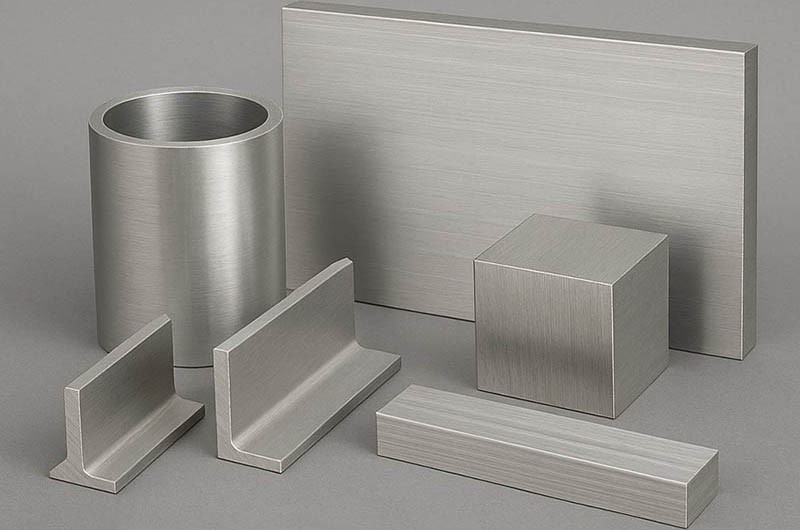

The specification of 5083 marine grade aluminum plate sheet

| Alloy | Temper | Thickness |

| 5083 | O, H111 | 3.00-50.00 |

| H116, H321 | 3.00-50.00 | |

| H112 | 6.00-50.00 |

Chemical composition of 5083 marine grade aluminum plate sheet

| Element | Composition % |

| Al | REM |

| Si | ≤0.4 |

| Cu | ≤0.10 |

| Mg | 4.0-4.9 |

| Zn | ≤0.25 |

| Mn | 0.40-1.0 |

| Ti | ≤0.15 |

| Cr | 0.05-0.25 |

| Fe | ≤0.40 |

| Note: Single≤0.05; Total≤0.15 | |

Mechanical properties of 5083 marine grade aluminum plate sheet

| Alloy | Temper | Thickness mm | Tensile Strength RmMPa | Specified non-proportional tensile strength Rp0.2 Mpa | Elongation% | |

| A50 mm | A | |||||

| 5083 | O | 3.00-50.00 | 275-350 | ≥125 | ≥16 | ≥14 |

| H111 | 3.00-50.00 | 275-350 | ≥125 | ≥16 | ≥14 | |

| H22, H32 | 3.00-6.00 | 305-380 | ≥215 | ≥8 | - | |

| H116 | 3.00-50.00 | ≥305 | ≥215 | ≥10 | ≥10 | |

| H321 | 3.00-50.00 | 305-385 | ≥215 | ≥12 | ≥10 | |

| H112 | 6.00-50.00 | ≥275 | ≥125 | ≥12 | ≥10 | |

How to choose the common temper of 5083 aluminum plate for ships?

Choosing the appropriate marine-grade aluminum plate state depends on specific application needs, including strength, corrosion resistance, machinability, and environmental conditions.

- 5083 H111: If you need a balance between strength and corrosion resistance but do not require extreme mechanical properties or corrosion resistance, the H111 state may be a suitable choice.

- 5083 H112: When your design requires higher strength but corrosion resistance and machinability are still important considerations, the H112 state is a good choice.

- 5083 H116: If your application requires excellent corrosion resistance, especially in saltwater environments, the H116 state offers the best anti-corrosion performance.

- 5083 H321: When you need to maintain high strength and durability in harsh environments, the H321 state provides optimal performance stability and durability.

Selection Recommendations:

- Consider the environment: If the aluminum plate will be exposed to harsh conditions (e.g., marine environments), prioritize states with stronger corrosion resistance (e.g., H116 or H321).

- Evaluate load requirements: For structural components that need to bear significant loads, choose states with higher strength (e.g., H112 or H321).

- Machinability requirements: Consider the machining performance of the aluminum plate and select a state that meets your processing needs (e.g., H112 is suitable for applications with higher machining requirements).

Marine aluminum products you may be interested in

You might be interested in: Marine Grade Aluminum 5083 5 Series Marine Aluminum 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum