Marine Grade Aluminum Plate: 5083 H111 VS 5083 H321

Last Updated :

5083-H111 and 5083-H321 are both suitable for marine-grade applications, but the specific choice should be determined based on the specific application requirements. H111 focuses more on workability and formability, while H321 emphasizes strength and fatigue life.

5083 aluminum plates are widely used in marine and shipbuilding due to their excellent corrosion resistance and high strength. 5083 marine-grade aluminum plates belong to the 5xxx Al-Mg alloy. It is a typical anti-rust aluminum plate with good corrosion resistance, excellent weldability, and good cold workability.

5083 alloy is a non-heat-treatable high-magnesium aluminum alloy, renowned for its excellent corrosion resistance and good weldability. The difference between H111 and H321 tempers lies in the degree and type of strain hardening and stabilization they undergo:

- 5083-H111 temper is slightly strain hardened compared to the H11 temper. It offers moderate strength and excellent formability, commonly used in applications requiring bending and deep drawing.

- 5083-H321 temper is equivalent to the H32H temper—strain hardened to about one-quarter hardness, then stabilized at a low temperature. It has higher yield strength and tensile strength than H111, offers better stress corrosion resistance, and retains strength better in welded structures.

Comparison Table of 5083 H321 and H111

| Property | 5083-H111 | 5083-H321 |

| Strength | Moderate tensile/yield strength | Higher tensile/yield strength |

| Ductility | High elongation, better formability | Lower elongation, stiffer |

| Corrosion Resistance | Good, but slightly inferior to H321 | Excellent, especially outstanding resistance to stress corrosion |

| Weldability | Excellent, suitable for complex welded structures | Excellent, better post-weld strength stability |

| Workability | Excellent cold workability, easy to form | Requires stabilization, slightly more difficult to process |

| Processing | Annealed + light strain hardening | Strain hardened + stabilized |

| Best For | Forming, welding, marine superstructures | High-stress structural components |

5083 H321 vs H111 Temper Designation Definitions

5083-H111

- Designation: H111 (H1x series).

- Process: Light cold working (strain hardening), exceeding the minimum for H11 level, but without subsequent stabilization treatment.

- Final Microstructure: Slight increase in dislocation density; maintains excellent ductility and formability.

5083-H321

- Designation: H321 (a variant of H32).

- Process: Cold worked to approximately ¼-hard temper (typical of H32), followed by a low-temperature “stabilization” heat treatment to lock in the dislocation structure and prevent annealing during service.

- Final Microstructure: Higher dislocation density than H111, but stable against recovery or recrystallization at moderate service temperatures.

5083 h321 and h111 Mechanical Property Comparison

Below are typical properties for 3 mm–10 mm 5083 sheet in both tempers (values will vary slightly by mill and exact thickness):

| Property | 5083 H111 | 5083 H321 |

| Tensile Strength (UTS) | 275–310 MPa | 320–350 MPa |

| Yield Strength (0.2% Offset) | ≈ 125 MPa | ≈ 145 MPa |

| Elongation at Break | 12–18 % | 8–12 % |

| Hardness (Brinell) | 60–70 HB | 75–85 HB |

5083 H321 vs H111 Corrosion Resistance

Corrosion: Both tempers offer excellent seawater and industrial corrosion resistance inherent to the 5083 alloy. The stabilization process of H321 provides slightly improved protection against stress corrosion cracking in welded areas.

Due to the high magnesium content (approximately 4–4.9%) and a protective oxide layer, both tempers perform excellently in marine environments. However:

- 5083 H111: More resistant to stress corrosion cracking.

- 5083 H321: Enhanced intergranular corrosion resistance after stabilization treatment.

5083 H321 vs H111 Weldability and Formability

Weldability: Both materials can be welded using all common welding methods. However, H321 often retains more post-weld strength due to its stable structure, which resists excessive softening in the heat-affected zone.

- H111: Easier to weld and form due to its ductility. Welded areas exhibit strength close to the base material.

- H321: Welding can reduce strength in the heat-affected zone to annealed (O temper) levels (yield strength around 145 MPa). In addition, H321 is more difficult to bend and more prone to cracking during forming.

5083 H321 vs H111 Typical Applications

| Temper | Typical Application Fields | Specific Application Parts | Features and Applicable Scenarios |

| 5083 H111 | Marine Industry | Hull, Console | Suitable for components requiring high formability, easy to fabricate into complex structures |

| General Applications | Vehicle Fuel Tanks, Hardware Products | Used for parts requiring good cold workability, such as bending and deep-drawn components | |

| 5083 H321 | Core Marine Structures | Decks, Bottom Outer Plates | Suitable for critical structural parts requiring high strength and excellent seawater corrosion resistance |

| Special Requirement Scenarios | LNG Storage Tanks, High-Pressure Switch Housings | Used in harsh environments requiring resistance to stress corrosion cracking, especially suitable for marine and energy sectors |

- H111: Preferred when maximum formability is required (e.g., for complex shapes).

- H321: Suitable for structural plates and welded components with strict post-weld strength requirements.

5083 H321 vs H111 Manufacturing Process

5083 H111

- Produced through annealing (heating followed by slow cooling) and slight strain hardening.

- After production, the material is softer and more ductile, making it ideal for forming and welding.

5083 H321

- Produced through strain hardening (cold working) followed by stabilization annealing (low-temperature heat treatment).

- Enhanced strength and stability make it harder and more stress-resistant.

5083 H321 vs H111 Selection Recommendation

- Prefer 5083 H111: For scenarios requiring complex cold working or cost-sensitive applications.

- Prefer 5083 H321: For critical components exposed to long-term marine environments or requiring higher structural strength.

Marine Grade Aluminum Plate 5083

- Marine Aluminum Alloy Series: 5xxx Al-Mg alloy

- Common Tempers: O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114, H116, H321

- Widely Used Tempers: H112, H116, H321, H111

- Applications: 5083 marine-grade aluminum plates are widely used in the production of tanks, automotive fuel tanks, bus bodies, and shipbuilding.

Marine Grade Aluminum Plate 5083 H111

Heat Treatment Condition: H111 temper is lightly strain-hardened. It is essentially in the annealed (O) condition but slightly deformed, enhancing its strength.

Key Characteristics:

- High Corrosion Resistance: It is highly suitable for marine environments due to its excellent seawater corrosion resistance.

- Good Formability: The H111 temper has good ductility and workability, making it suitable for complex forming processes.

- Moderate Strength: Although its strength is lower than that of H321 temper, it still provides adequate strength for marine applications.

Marine Grade Aluminum Plate 5083 H321

Heat Treatment Condition: H321 temper is stabilized by heat treatment, optimizing the aluminum plate's strength after thermal processing while maintaining excellent corrosion resistance.

Key Characteristics:

- Excellent Corrosion Resistance: Like H111 temper, H321 offers excellent corrosion resistance in seawater and other harsh environments.

- Higher Strength: Compared to H111, H321 temper has higher strength, making it suitable for structural components that require higher load-bearing capacity.

- Improved Fatigue Strength: After treatment, H321 temper exhibits higher fatigue resistance under repetitive loads.

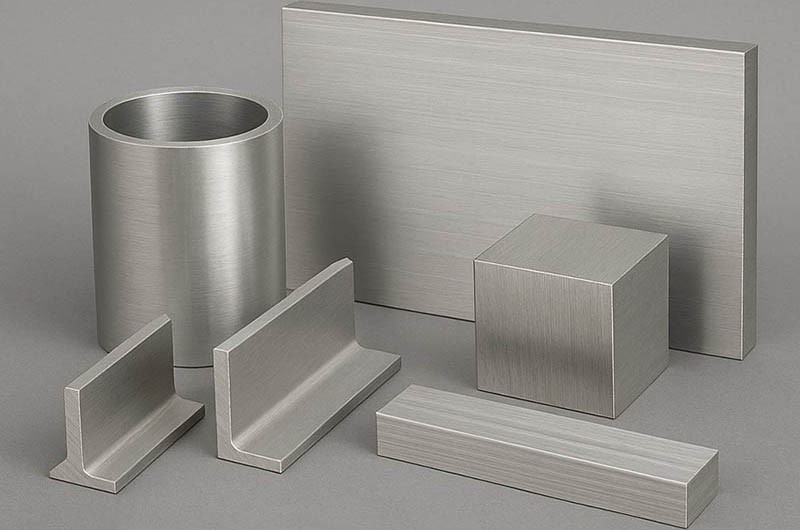

Marine aluminum products you may be interested in

You might be interested in: Marine Grade Aluminum 5083 Marine Aluminum 5083 h321 5 Series Marine Aluminum 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum