Applications of 5083 Aluminum Plate in Shipbuilding

Last Updated :

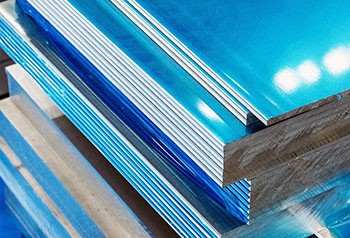

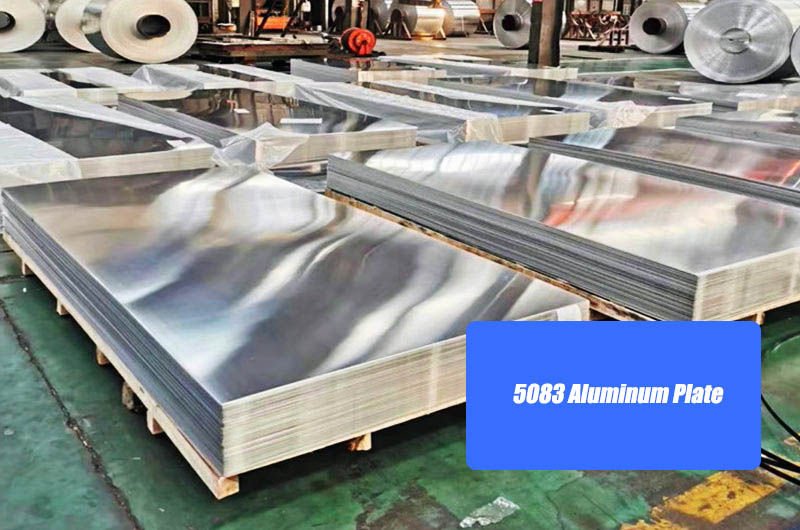

The comprehensive properties of 5083 aluminum plate make it an ideal choice for shipbuilding. Its excellent mechanical performance, corrosion resistance, and lightweight characteristics play a crucial role in ship design and construction.

One of the main applications of 5083 aluminum plate is in the marine industry, where its high resistance to corrosion, saltwater, and seawater makes it an ideal choice. Shipbuilders use it to construct various parts of ships, including hulls, yachts, cruise ships, and offshore platforms.

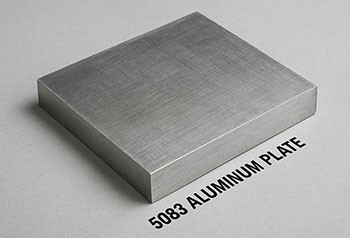

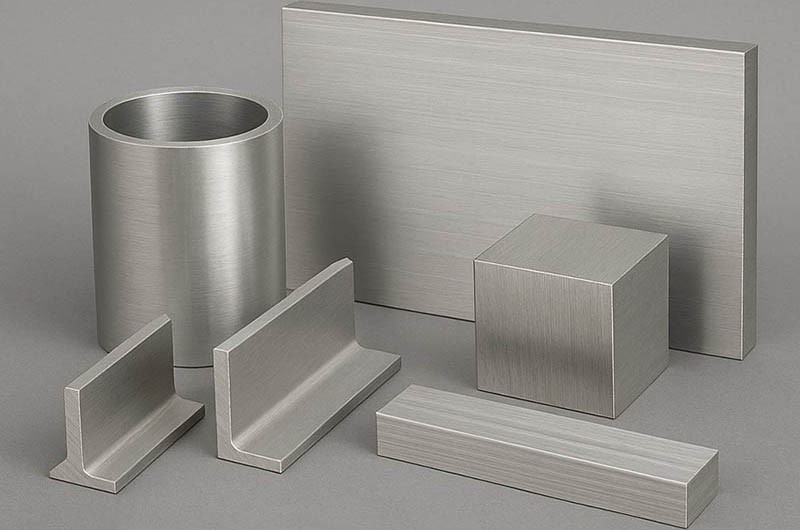

Features of 5083 Aluminum Plate

1. Corrosion Resistance

Superior Corrosion Resistance: The corrosion resistance of 5083 aluminum plate is outstanding, allowing it to remain stable in various corrosive environments. This makes it particularly suitable for marine environments where seawater's corrosive effects are severe.

2. Weldability

Excellent Weldability: 5083 aluminum plate has good weldability, suitable for various welding processes. The weld joints are strong and stable, ensuring the structural integrity and reliability in shipbuilding.

3. Formability

Excellent Formability: This aluminum plate has good formability during processing, allowing it to be easily shaped into complex parts and structures.

4. Strength

High Strength: 5083 aluminum plate offers high strength, capable of withstanding significant loads and pressures. It is suitable for load-bearing structures and high-strength applications.

5. Cold Working Performance

Excellent Cold Working Performance: Under low-temperature conditions, 5083 aluminum plate maintains excellent processing performance, enabling various cold working operations without significantly affecting its properties.

Applications of Marine 5083 Aluminum Plate

1. 5083 Aluminum Plate for Hulls

Main Application: 5083 aluminum plate is widely used in the hull structures of ships, providing the necessary strength and corrosion resistance to handle harsh marine environments.

2. 5083 Aluminum Plate for Operations Platforms

Structural Components: 5083 aluminum is used in ship's operations platforms due to its good corrosion resistance and strength, ensuring stability during long-term use.

3. 5083 Aluminum Plate for Decks

Durable Material: In the deck sections of ships, 5083 aluminum plate can withstand seawater corrosion and everyday wear, extending its service life.

Marine 5083 Aluminum Plate Typical Tempers

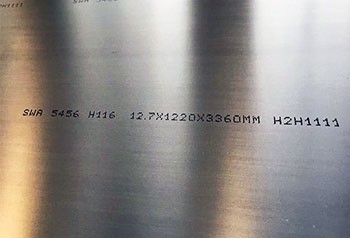

5083 H116 Aluminum Plate

Corrosion Resistance: This temper of aluminum plate is particularly suitable for parts in direct contact with seawater, offering excellent corrosion resistance and long-term usability without damage.

5083 H321 Aluminum Plate

Durability: Similar to 5083 H116, 5083 H321 aluminum plate also has exceptional corrosion resistance, making it ideal for marine applications requiring high durability.

Why Choose 5083 Aluminum Plate for Marine Applications?

1. High Strength-to-Weight Ratio and Modulus Ratio

Enhanced Yield Strength: 5083 aluminum plate has an excellent strength-to-weight ratio (strength relative to density) and modulus ratio (modulus relative to density), which effectively reduces the overall weight of the ship's structure while maintaining strength. This is crucial for improving ship performance and efficiency, especially when reducing hull weight is necessary.

2. Excellent Weldability

Weldability: 5083 aluminum plate has very good weldability, ensuring strength and stability of weld joints during processing. The alloy is easy to weld and resistant to cracking or defects, ensuring the overall integrity and safety of the ship's structure.

3. Exceptional Corrosion Resistance

Corrosion Resistance: 5083 aluminum plate offers strong corrosion resistance, making it particularly suitable for marine environments. It resists seawater corrosion and does not easily rust or corrode, ensuring long-term exposure in harsh conditions and contributing to the ship’s durability and reliability.

4. Lightweight and Efficient

Low Density: Compared to traditional steel plates, 5083 aluminum plate has a lower density, which means it is lighter for the same volume. This reduces the weight of the hull, helping to increase the ship's load capacity and improve fuel efficiency, thus optimizing overall performance.

5. Easy to Process and Form

Easy to Process: The good formability of 5083 aluminum plate makes it easy to process and shape, allowing for the manufacture of complex parts and structures. This processing feature is particularly important for precision requirements in shipbuilding.

Chemical composition of 5083 aluminium plate

| Element | Composition % |

| Al | REM |

| Si | ≤0.4 |

| Cu | ≤0.10 |

| Mg | 4.0-4.9 |

| Zn | ≤0.25 |

| Mn | 0.40-1.0 |

| Ti | ≤0.15 |

| Cr | 0.05-0.25 |

| Fe | ≤0.40 |

| Note: Single≤0.05; Total≤0.15 | |

Mechanical properties of 5083 alloy aluminum plate

| Tensile strength (σb) | 110-136MPa |

| Yield strengthσ0.2 (MPa) | ≥110 |

| Elongationδ10 (%) | ≥20 |

| Elastic modulus (E) | 69.3~70.7Gpa |

| Annealing temperature | 415℃ |

Marine aluminum products you may be interested in

You might be interested in: Marine Grade Aluminum 5083 5 Series Marine Aluminum Aluminum for Shipbuilding 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum