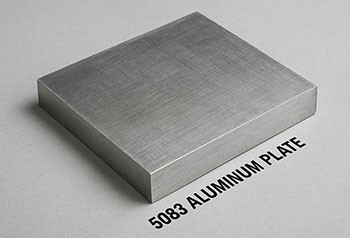

5083 Marine Aluminum Plate for LNG Storage Tanks

Last Updated :

The primary reason for using 5083 marine aluminum plates in LNG storage tanks is due to their superior performance and characteristics. The 5083 marine aluminum plate can significantly enhance the durability and safety of LNG storage tanks, particularly in extreme environments.

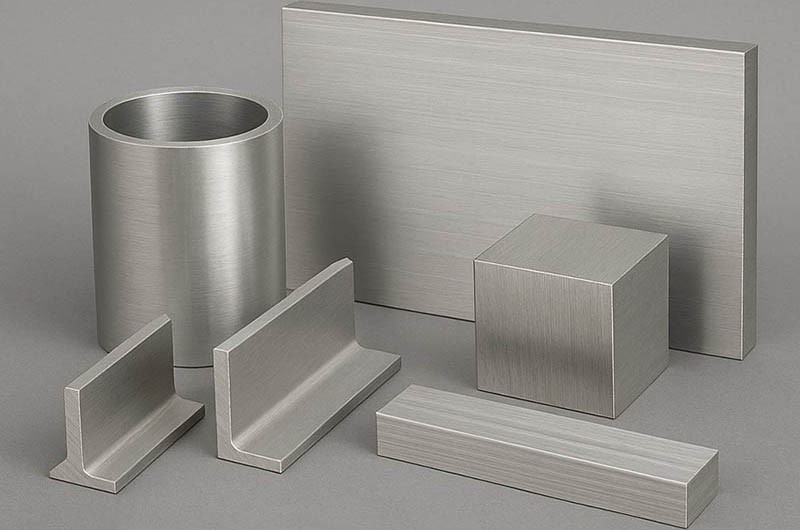

The aluminum alloy used in LNG storage tanks is predominantly 5083 aluminum plate, which is an excellent material for manufacturing LNG storage tanks. This is not only because it is a cryogenic structural material but also because it is easy to process and form, while also having good weldability and a high recycling rate.

Advantages of 5083 Marine Aluminum Plate for LNG Storage Tanks

- 1. Excellent Corrosion Resistance: The 5083 aluminum plate has strong corrosion resistance to seawater and other corrosive environments, which is crucial for the use of LNG storage tanks in marine or humid environments.

- 2. High Strength: The 5083 aluminum alloy is characterized by high strength, enabling it to withstand significant pressure and external impacts, which is essential for the safety of LNG storage tanks.

- 3. Good Weldability: The 5083 aluminum plate can be welded into complex shapes and structures, which is very helpful in the manufacturing process of LNG storage tanks.

- 4. Excellent Low-Temperature Performance: LNG storage tanks need to operate in low-temperature environments. The 5083 aluminum alloy can maintain good mechanical properties at low temperatures without becoming brittle.

- 5. Lightweight: Aluminum alloys are lighter than steel, which can reduce the overall weight of the storage tank and improve the convenience of transportation and installation.

Common Specifications of 5083 Aluminum Plate for LNG Storage Tanks

- Thickness: 5mm, 6mm, 8mm, 10mm, 12mm, etc.

- Width: 2000mm, 2200mm, 2500mm, etc.

- Length: 6000mm, 8000mm, 10000mm, etc.

Chemical Composition of 5083 Aluminum Plate for LNG Storage Tanks

| Element | Composition Range |

| Aluminum (Al) | 95.2% - 98.5% |

| Magnesium (Mg) | 4.0% - 4.9% |

| Manganese (Mn) | 0.4% - 1.0% |

| Chromium (Cr) | 0.05% - 0.25% |

| Others (each) | ≤ 0.05% |

| Others (total) | ≤ 0.15% |

| Remainder | Aluminum (balance) |

Mechanical Properties of 5083 Aluminum Plate for LNG Storage Tanks

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| H116 | 270 - 345 | 115 - 240 | 12 - 20 | 75 - 105 |

| H321 | (not specified) | (not specified) | (not specified) | (not specified) |

| O | (not specified) | (not specified) | (not specified) | (not specified) |

FAQs about aluminum plates for LNG storage tanks

1. What is LNG, and why is aluminum used for its storage tanks?

LNG is natural gas that has been cooled to a liquid state at about -162°C (-260°F). It is stored in insulated tanks to maintain this low temperature. Aluminum is commonly used for these tanks due to its excellent low-temperature strength, corrosion resistance, and lightweight properties.

2. What types of aluminum alloys are typically used in LNG storage tanks?

The most common aluminum alloy used is 5083, which is a high-strength, corrosion-resistant alloy. Other alloys like 5456 and 5383 are also used, depending on specific requirements.

3. Why is corrosion resistance important for LNG storage tanks?

Corrosion resistance is crucial because it ensures the longevity and safety of the storage tanks, especially since they are often exposed to harsh marine environments or cryogenic conditions.

4. What are the advantages of using aluminum over other materials for LNG tanks?

Aluminum offers several advantages, including:

- Lightweight: Reduces overall weight, which is crucial for large-scale storage and transport.

- High Strength at Low Temperatures: Unlike many materials, aluminum maintains its strength even at cryogenic temperatures.

- Corrosion Resistance: Minimizes maintenance and extends the lifespan of the tank.

5. How are aluminum plates for LNG tanks manufactured?

Aluminum plates are typically manufactured through a process of rolling. They are then heat-treated and sometimes subjected to additional processing like cladding to improve their performance characteristics.

6. What is the typical thickness of aluminum plates used in LNG storage tanks?

The thickness of aluminum plates can vary, but it generally ranges from 5 mm to 50 mm, depending on the design and specifications of the tank.

7. Are there any specific standards or certifications required for aluminum plates used in LNG tanks?

Yes, aluminum plates used in LNG storage tanks must comply with international standards such as ASTM, EN, and ISO. Additionally, the plates may require certification from classification societies like Lloyd's Register or DNV GL.

Marine aluminum products you may be interested in

You might be interested in: Marine Grade Aluminum 5083 5 Series Marine Aluminum 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum