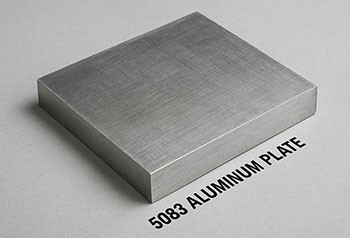

Classification society certified 5083 h321 aluminum plate

Last Updated :

5083 aluminum plate is a high-quality 5-series aluminum-magnesium alloy, widely used in applications such as shipbuilding and tankers due to its exceptional corrosion resistance and high tensile strength. This aluminum plate offers outstanding overall performance, making it an ideal material choice for various harsh environments.

5083 H321/H111/H116 marine aluminum plates have notable features, including high strength at low temperatures and a lightweight design, providing reliable safety for oceanic transportation. The strength of this aluminum plate is particularly outstanding in cold environments.

Haomei Aluminum can provide a range of marine certifications based on customer requirements, including China Classification Society (CCS), Bureau Veritas (BV), Lloyd's Register (LR), American Bureau of Shipping (ABS), Korean Register (KR), Det Norske Veritas (DNV), Italian Register (RINA), and other international certification bodies such as PC. These certifications ensure the safety and quality standards of the aluminum plates worldwide.

The 5083-H321 aluminum plate is a high-strength aluminum alloy specifically designed for marine-grade applications, offering excellent performance, especially suited for harsh marine environments and other demanding applications. The H321 temper indicates that the material has undergone strain hardening and stabilization treatment, which enhances its stress corrosion cracking resistance in marine environments. With its high strength, excellent corrosion resistance, and good weldability, the 5083-H321 aluminum plate is a trusted choice for applications requiring extreme durability and superior performance.

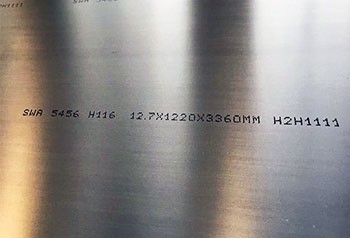

Marine Aluminum Plate 5083 H321 Specifications

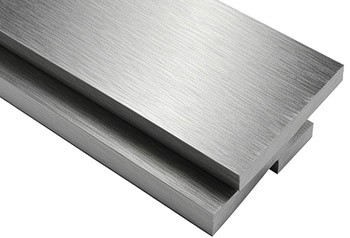

- Thickness: 3mm to 50mm

- Width: 1,000mm to 2,600mm

- Length: 2,000mm to 12,000mm

- Standard Size: 1500x6000mm;2000mm*6000mm;2000mm*8000mm;2000mm*9000mm;

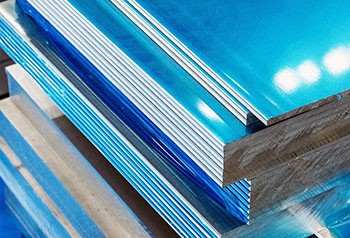

- Surface: mill finish surface,Blue PVC films or paper-interleaved

We also produce as your requirement

Marine Aluminum Plate 5083 H321 Features

- 1. High Strength: The 5083 H321 aluminum plate offers superior mechanical strength, characterized by high tensile and yield strength. Its structural properties make it outstanding in handling heavy loads and pressures, particularly suited for applications with strict strength requirements.

- 2. Excellent Corrosion Resistance: This aluminum alloy exhibits strong corrosion resistance in harsh marine environments and severe industrial conditions. It effectively withstands the erosion from seawater and industrial chemicals, ensuring structural integrity over long-term use and reducing maintenance and replacement frequency.

- 3. Good Weldability: The 5083 H321 aluminum plate has excellent weldability, suitable for various welding methods, such as Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and resistance welding. This allows for efficient and reliable connections to other materials or components during manufacturing and repair processes.

- 4. Excellent Machinability: This aluminum plate has good forming capabilities, allowing it to be easily machined into various complex shapes and structures during manufacturing. This feature makes it an ideal choice for applications requiring precision design and intricate geometries.

- 5. High Fatigue Resistance: Under repeated cyclic loads and dynamic stresses, the 5083 H321 aluminum plate performs exceptionally well. Its high fatigue resistance makes it particularly suitable for structures subjected to vibrations, impacts, and other dynamic forces, ensuring stability and durability over long-term use.

Is 5083 Aluminum Marine Grade?

Yes, 5083 aluminum is typically classified as a marine-grade aluminum alloy. It is renowned for its excellent corrosion resistance, high strength, and good weldability, making it particularly suitable for use in marine environments. These characteristics make 5083 aluminum widely used in structural components of ships, hulls, and other areas exposed to seawater for extended periods. The 5083 H321 temper is especially suited for shipbuilding because it maintains excellent strength and corrosion resistance after processing.

Why Choose Haomei Aluminum for Marine Grade 5083 Aluminum Plates?

- 1. Extensive Production Experience: Haomei Aluminum is a well-known manufacturer with years of rich production experience. The company specializes in producing a wide range of aluminum alloys from Series 1 to 8, with strong production capabilities to handle large orders from 3 to 5,000 tons, ensuring timely delivery.

- 2. Advanced Equipment: The company is equipped with advanced production facilities, including six-roll cold rolling mills. These machines can produce ultra-wide aluminum plates, with widths up to 2600 millimeters, meeting customers' needs for large-sized aluminum plates.

- 3. Competitive Pricing: Haomei Aluminum offers comprehensive one-stop services, from pre-sales consultation to in-sales support and after-sales service, always focusing on customer needs. Additionally, the company provides competitive pricing, helping customers control costs effectively while ensuring quality.

Chemical composition of 5083 h321 aluminium plate

| Element | Composition % |

| Al | REM |

| Si | ≤0.4 |

| Cu | ≤0.10 |

| Mg | 4.0-4.9 |

| Zn | ≤0.25 |

| Mn | 0.40-1.0 |

| Ti | ≤0.15 |

| Cr | 0.05-0.25 |

| Fe | ≤0.40 |

| Note: Single≤0.05; Total≤0.15 | |

Mechanical properties of 5083 h321 aluminium plate

| Alloy | Temper |

Rm(Mpa) Tensile strength |

Rp0.2(MPa) Yield strength |

Elongation A(%) |

Exfoliation corrosion |

Intergranular corrosion Mg/cm2 |

Certification |

| 5083 | O/H111/H112 | ≥275 | ≥125 | ≥16 | - | - | DNV, GL, ABS, CCS, BV, LR |

| H116 | ≥305 | ≥215 | ≥10 | ≦PB | ≦15 | ||

| H321 | 305-385 | 215-295 | ≥12 |

Marine Aluminum Plate 5083 H321 Applications

5083 H321 marine aluminum is widely used in various types of ship structures due to its exceptional performance. It is commonly used to manufacture key components such as ship engine bases, decks, bulwarks, and hull outer plates. This aluminum material is not only extensively used in yacht and cruise ship hulls but also effectively enhances the durability and corrosion resistance of the hull, ensuring long-term stable operation in marine environments.

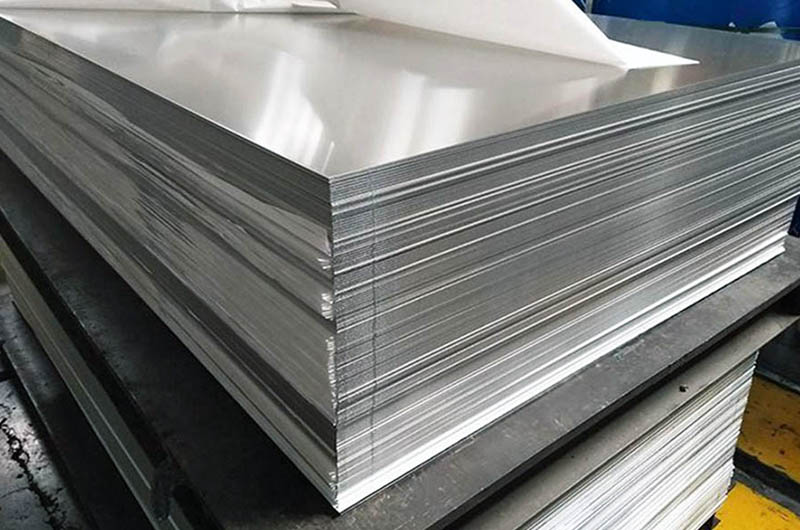

Marine Aluminum Plate 5083 H321 Packaging and Transportation

1. Packaging of 5083 H321 Aluminum Plates

Packaged using export-grade wooden crates or pallets.

Use fumigated wooden pallets with a fumigation certificate.

2. Transportation Environment Requirements

5083 H321 aluminum plates must be stored separately from active chemicals and moisture during transportation.

The transport vehicle or container must be kept dry, clean, and free of contaminants.

3. Transportation Methods

Typically transported using enclosed vehicles or containers.

For extra-long 5083 H321 aluminum plates or when using open trucks, special boxes, or containers, the cargo must be tightly covered and secured with waterproof covers to prevent water, rain, or snow from entering the packaging and aluminum products.

4. Storage Requirements

5083 H321 aluminum plates are usually stored in warehouses during transit.

If outdoor storage is necessary, the aluminum plates must be tightly covered and secured with rainproof cloth. The plates should be elevated from the ground with a minimum thickness of 100 millimeters.

5. Protective Measures

Moisture-proof packaging measures should be taken during transportation to prevent the aluminum plates from getting damp.

Handle with care during loading and unloading to avoid collisions, ensuring that the 5083 H321 aluminum plates are delivered to the customer’s warehouse safely and without damage.

Marine aluminum products you may be interested in

You might be interested in: Marine Grade Aluminum 5083 Marine Aluminum 5083 h321 5 Series Marine Aluminum 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum