Advantages of 5083 H116 Aluminum in Shipbuilding

Last Updated :

The advantages of 5083 H116 aluminum alloy in the shipbuilding industry are primarily reflected in its exceptional corrosion resistance, high strength, excellent weldability, and low density, making it an ideal material for manufacturing high-performance ships and marine structures.

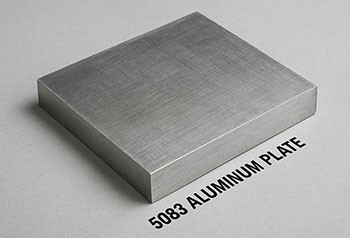

What is marine grade Aluminium 5083 H116?

Marine grade Aluminum 5083 H116 is a specialized aluminum alloy designed for marine environments, renowned for its excellent corrosion resistance and high strength.

- Alloy Composition: 5083 aluminum alloy primarily consists of aluminum, magnesium, and manganese. Its composition provides outstanding resistance to corrosion in marine environments, particularly to seawater.

- H116 Temper: The H116 temper indicates that the alloy has undergone a specific heat treatment process to enhance its strength and toughness. In the H116 condition, 5083 aluminum alloy exhibits high strength and maintains good toughness at low temperatures.

Advantages of 5083 H116 Aluminum Alloy in Shipbuilding

- Excellent Corrosion Resistance: 5083 H116 aluminum alloy offers exceptional resistance to seawater corrosion, making it one of the most corrosion-resistant aluminum alloys available, ideal for shipbuilding.

- High Strength: In the H116 temper, 5083 aluminum alloy demonstrates high strength while retaining good toughness even at low temperatures, suitable for applications requiring strength and impact resistance, such as hull structures.

- Superior Weldability: 5083 aluminum alloy provides excellent weldability, supporting various welding methods such as TIG and MIG. This is crucial for welding operations in shipbuilding.

- Low Density: The low density of aluminum helps reduce the overall weight of the vessel, improving fuel efficiency and speed, which is a significant advantage in ship design.

- Good Machinability: 5083 aluminum alloy is easy to machine, allowing for complex structural designs through mechanical processing and forming, meeting the precision and design flexibility required in shipbuilding.

- Excellent Crack Resistance: Despite potential performance loss from welding, 5083 aluminum plates have excellent crack resistance, ensuring minimal performance difference in welded joints, which greatly benefits shipbuilding welding work.

- Good Cold and Hot Forming Properties: 5083 aluminum alloy performs well in both cold and hot forming processes during ship construction, without developing cracks, fully meeting the performance requirements of the shipbuilding industry.

The specification of 5083 marine grade aluminum plate sheet

| 5083 | Temper | Thickness |

| O, H111 | 3.00-50.00 | |

| H22, H32 | 3.00-6.00 | |

| H116, H321 | 3.00-50.00 | |

| H112 | 6.00-50.00 |

Chemical composition of 5083 marine grade aluminum plate sheet

| Element | Composition % |

| Al | REM |

| Si | ≤0.4 |

| Cu | ≤0.10 |

| Mg | 4.0-4.9 |

| Zn | ≤0.25 |

| Mn | 0.40-1.0 |

| Ti | ≤0.15 |

| Cr | 0.05-0.25 |

| Fe | ≤0.40 |

| Note: Single≤0.05; Total≤0.15 | |

Mechanical properties of 5083 marine grade aluminum plate sheet

| Alloy | Temper | Thickness mm | Tensile Strength RmMPa | Specified non-proportional tensile strength Rp0.2 Mpa | Elongation% | |

| A50 mm | A | |||||

| 5083 | O | 3.00-50.00 | 275-350 | ≥125 | ≥16 | ≥14 |

| H111 | 3.00-50.00 | 275-350 | ≥125 | ≥16 | ≥14 | |

| H22, H32 | 3.00-6.00 | 305-380 | ≥215 | ≥8 | - | |

| H116 | 3.00-50.00 | ≥305 | ≥215 | ≥10 | ≥10 | |

| H321 | 3.00-50.00 | 305-385 | ≥215 | ≥12 | ≥10 | |

| H112 | 6.00-50.00 | ≥275 | ≥125 | ≥12 | ≥10 | |

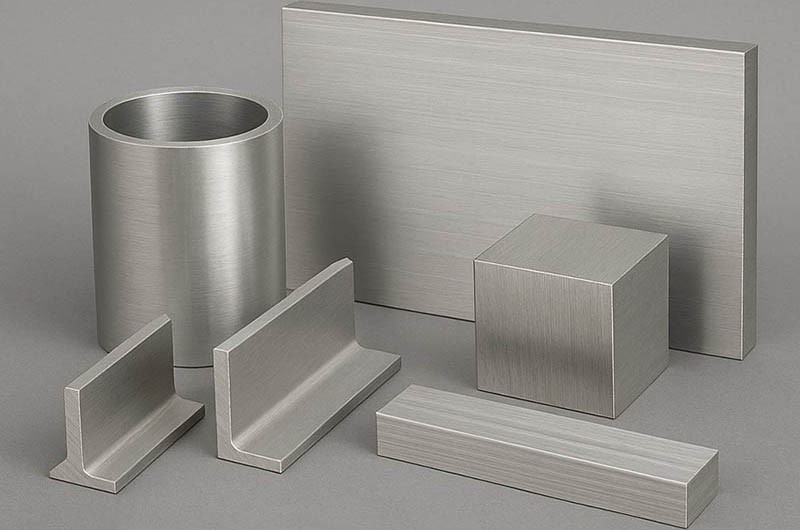

Marine aluminum products you may be interested in

You might be interested in: Marine Grade Aluminum 5083 5 Series Marine Aluminum Aluminum for Shipbuilding 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum