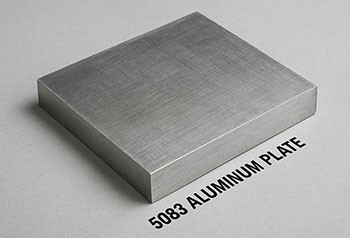

5083 aluminum plate for yacht

Last Updated :

5083 aluminum plates are ideal materials for yachts and other marine facilities due to their excellent corrosion resistance and high strength. This aluminum alloy is widely used in various types of vessels, including small fishing boats, yachts, speedboats, and large liners.

The advantages of 5083 aluminum plates lie in their outstanding welding performance, formability, and resistance to marine environments, making them highly suitable for various parts of a ship. Specific applications include hull side plates, bottom outer plates, keels, ribs, engine mounts, chimneys, and masts. These components need to withstand harsh marine environments and structural stresses, so 5083 aluminum plates are the preferred material for these critical parts due to their excellent performance.

Performance Characteristics of 5083 Aluminum Plate

- Excellent Corrosion Resistance: 5083 aluminum plates exhibit outstanding corrosion resistance in marine environments. They are particularly adept at resisting corrosion caused by chlorides and effectively withstand salt spray and other corrosive substances in the marine environment. This exceptional corrosion resistance ensures that 5083 aluminum plates maintain stability and extend their service life when exposed to seawater for extended periods.

- High Strength and Excellent Impact Resistance: 5083 aluminum plates possess excellent tensile strength and impact resistance. Their high strength allows them to endure significant external loads and impacts, ensuring the structural stability and durability of the vessel. This strength enables 5083 aluminum plates to effectively maintain structural integrity and safety in harsh marine conditions.

- Excellent Weldability: 5083 aluminum plates have excellent welding properties and can accommodate various welding methods, including argon arc welding, TIG welding, and MIG welding. This welding convenience not only simplifies the manufacturing and repair processes but also ensures the strength and reliability of weld joints. Whether in the manufacturing or repair of the hull, the welding characteristics of 5083 aluminum plates meet high standards of craftsmanship.

Specifications of 5083 Aluminum Plate

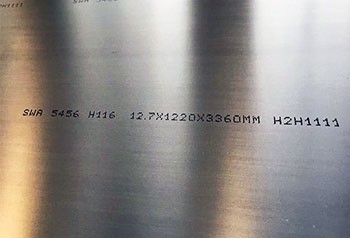

- Common States: H116, H321, H112

- Thickness (mm): 0.5-500

- Width (mm): 20-2650

- Length (mm): 500-16000

Common thicknesses of 5083 marine aluminum plates include 1mm, 2mm, 3mm, 4mm, and 5mm, with the specific choice depending on the hull structure, vessel specifications, and usage area.

In practical applications, the states of 5083 aluminum plates mainly include H116, H321, and H112. The choice of state affects the performance and suitability of the aluminum plate. To achieve lightweight hull designs, thin plates are more commonly used. Typical thin plate thicknesses are 1.6mm and above, while thicker plates of 30mm and above are used for parts requiring higher strength. The standard length of the plates is 2m, and the width is 6m. These dimensions help reduce welding seams and optimize the manufacturing process. In large vessels, aluminum plates with a width of 2.5m are commonly used to further improve manufacturing efficiency and reduce welding seams.

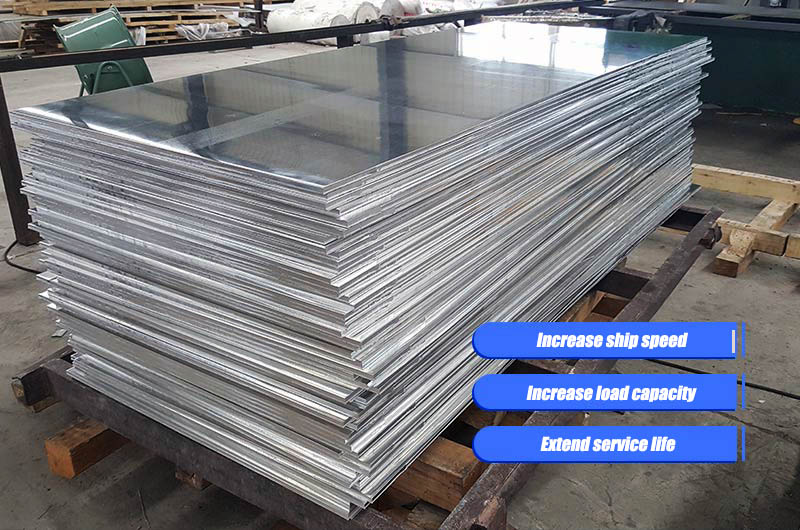

Advantages of 5083 Marine Aluminum Plate

The use of 5083 aluminum plates in shipbuilding not only brings the benefit of lightweight design but also significantly enhances the overall performance of the vessel in several aspects.

- Increased Speed: 5083 aluminum plates have high strength and low weight, allowing vessels to reduce their own weight while maintaining structural stability. Lightweight hull design helps reduce water surface resistance, thereby improving the vessel's speed and fuel efficiency.

- Increased Load Capacity: Due to the high strength characteristics of 5083 aluminum plates, vessels can increase effective payloads while reducing their weight. This not only enhances the vessel's carrying capacity but also optimizes cargo transportation and operational flexibility.

- Extended Service Life: The excellent corrosion resistance of 5083 aluminum plates ensures superior performance in marine environments, effectively resisting salt spray, moisture, and other corrosive substances. This corrosion resistance significantly extends the vessel's service life, reducing maintenance and replacement frequency, and lowering long-term operating costs.

The use of 5083 aluminum plates significantly improves the vessel's performance, economy, and durability.

Chemical composition of 5083 marine grade aluminum plate sheet

| Element | Composition % |

| Al | REM |

| Si | ≤0.4 |

| Cu | ≤0.10 |

| Mg | 4.0-4.9 |

| Zn | ≤0.25 |

| Mn | 0.40-1.0 |

| Ti | ≤0.15 |

| Cr | 0.05-0.25 |

| Fe | ≤0.40 |

| Note: Single≤0.05; Total≤0.15 | |

Mechanical properties of 5083 marine grade aluminum plate sheet

| Alloy | Temper | Thickness mm | Tensile Strength RmMPa | Specified non-proportional tensile strength Rp0.2 Mpa | Elongation% | |

| A50 mm | A | |||||

| 5083 | O | 3.00-50.00 | 275-350 | ≥125 | ≥16 | ≥14 |

| H111 | 3.00-50.00 | 275-350 | ≥125 | ≥16 | ≥14 | |

| H22, H32 | 3.00-6.00 | 305-380 | ≥215 | ≥8 | - | |

| H116 | 3.00-50.00 | ≥305 | ≥215 | ≥10 | ≥10 | |

| H321 | 3.00-50.00 | 305-385 | ≥215 | ≥12 | ≥10 | |

| H112 | 6.00-50.00 | ≥275 | ≥125 | ≥12 | ≥10 | |

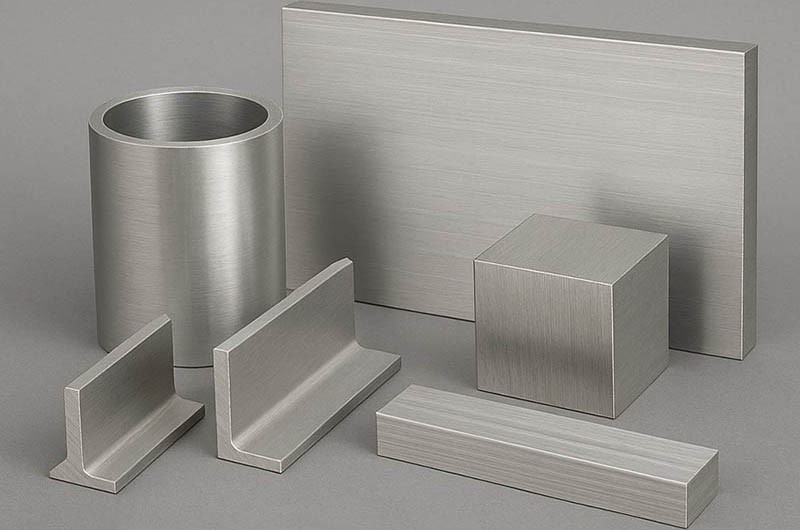

Applications of 5083 Aluminum Plate

Hull Structure: 5083 aluminum plates are widely used in yacht hull structures due to their outstanding corrosion resistance and high strength. The excellent corrosion resistance ensures that the hull maintains stability when exposed to marine environments over long periods, while the high strength provides the necessary structural support to withstand various pressures and impacts under marine conditions. This characteristic makes 5083 aluminum plates the material of choice in yacht manufacturing.

Marine Components: In addition to hull structures, 5083 aluminum plates are also used in manufacturing other critical components of yachts. This includes decks, bulkheads, hatches, and ship frames. These components require high strength and corrosion resistance to withstand various pressures and wear in the marine environment. The good machinability and weldability of 5083 aluminum plates enable high precision and reliability in the design and manufacturing of these components, while also reducing maintenance and repair needs.

Processing of 5083 Aluminum Plate

Processing: 5083 aluminum plates can be cut, bent, and processed, but it is important to avoid generating excessive heat during processing.

Maintenance: Regularly inspect the surface of 5083 aluminum plates during long-term use, and remove salt and dirt to help maintain their performance and appearance.

Haomei Aluminum 5083 marine aluminum plates are produced with trace amounts of Be, which effectively reduces the tendency for casting ingots to crack and improves surface quality issues of the rolled plates. This addition helps eliminate internal stress and prevents deformation during cutting.

Marine aluminum products you may be interested in

You might be interested in: Marine Grade Aluminum 5083 5 Series Marine Aluminum 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum