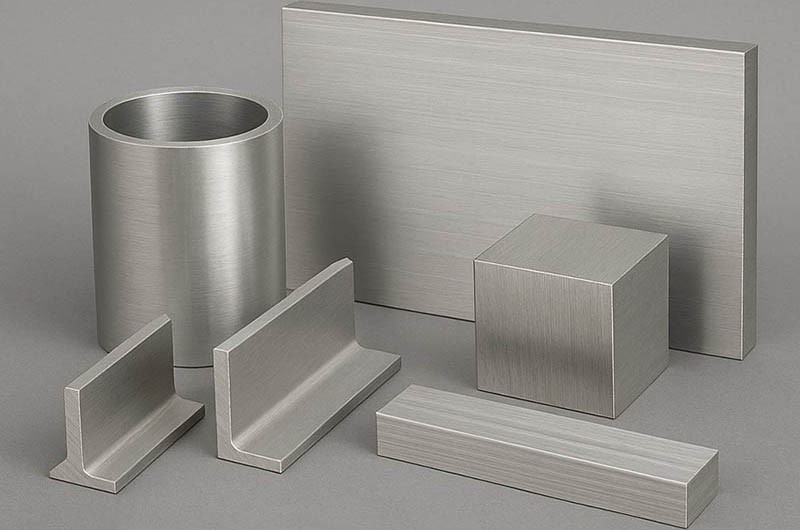

5083 5383 O H112 Marine Aluminum Square Bar

- 5083 Aluminum Square Bar is a commonly used aluminum-magnesium alloy product with excellent corrosion resistance and weldability, suitable for applications such as ship structures, pressure vessels, and cryogenic equipment. Excellent corrosion resistanceGood weldabilityMedium strength

- 5383 Aluminum Square Bar is an upgraded version of 5083, offering increased strength and hardness while maintaining excellent corrosion resistance, making it especially suitable for applications with higher material performance requirements. Higher strengthGreater hardnessExcellent low-temperature performance

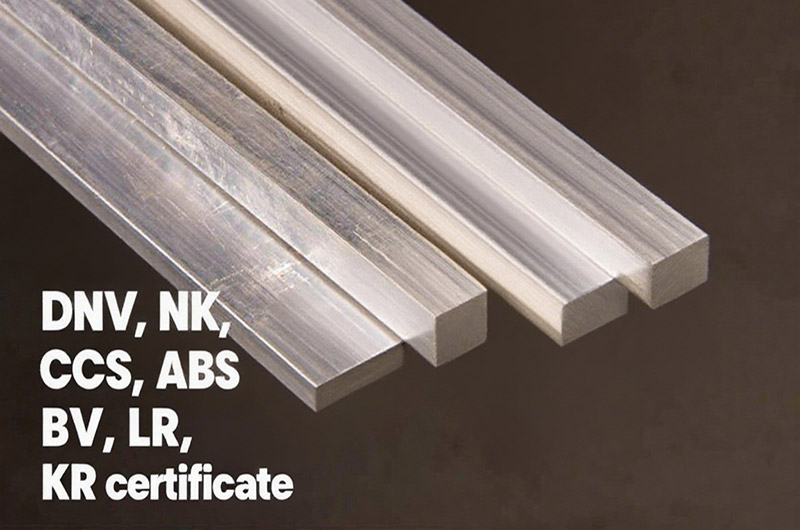

Why Choose Haomei's 5083 and 5383 Aluminum Square Bars?

Haomei’s aluminum square bars strictly conform to the quality standards of major global classification societies, including: China Classification Society (CCS), Det Norske Veritas (DNV), Nippon Kaiji Kyokai (NK), American Bureau of Shipping (ABS), Bureau Veritas (BV), Lloyd’s Register (LR), and Korean Register (KR).

The company fully implements international quality management systems for the shipbuilding industry to ensure that its 5083 and 5383 aluminum square bars deliver outstanding performance in seawater corrosion resistance, weldability, and impact resistance, meeting the high-quality application requirements of marine and shipbuilding fields.

Specifications of 5083 and 5383 Aluminum Square Bars

Standard Specifications of 5083 Aluminum Square Bar

5083 aluminum square bar is a commonly used aluminum-magnesium alloy product with excellent corrosion resistance and weldability. The main specification parameters of 5083 aluminum square bar are as follows:

Cross-Section Dimensions

The side length typically ranges from 10mm to 220mm to meet the needs of various application scenarios. Some suppliers can provide larger custom sizes, but most standard products fall within this range.

Length Specifications

Common lengths are 3000mm, 4000mm, and 6000mm. Some suppliers also offer custom lengths ranging from 1000mm to 12000mm, depending on production capacity and customer requirements.

Temper Conditions

5083 aluminum square bars are usually supplied in tempers such as O (annealed), H112 (strain hardened + partially annealed), H116 (strain hardened + stabilized), and H321 (strain hardened + partially annealed). Different tempers are suitable for different application environments and subsequent processing needs.

Standards

Products generally comply with ASTM B221, ASME SB211, GB/T 3191, JIS H4040 and other international and national standards to ensure quality and performance requirements are met.

Standard Specifications of 5383 Aluminum Square Bar

5383 aluminum square bar is an upgraded version of 5083, offering increased strength and hardness while maintaining excellent corrosion resistance. Its main specification parameters are as follows:

Cross-Section Dimensions

Side length specifications are basically consistent with 5083, typically ranging from 10mm to 220mm, and some suppliers can offer larger custom sizes.

Length Specifications

Standard lengths are 3000mm, 4000mm, and 6000mm. Other lengths can also be provided according to customer requirements.

Temper Conditions

5383 aluminum square bars are mainly supplied in tempers such as O (annealed), H112 (strain hardened + partially annealed), H116 (strain hardened + stabilized), and H321 (strain hardened + partially annealed) to meet the needs of different application scenarios.

Standards

Products conform to ASTM B221, ASME SB211, GB/T 3191 and other international and national standards, and have also passed certifications from classification societies such as DNV, ABS, and LR.

Chemical composition of 5083 5383 alloy

| Chemical | 5083 element % | 5383 element % |

| Si | 0.40 | 0.25 |

| Fe | 0.40 | 0.25 |

| Cu | 0.10 | 0.20 |

| Mn | 0.40-1.00 | 0.70-1.00 |

| Mg | 4.00-4.90 | 4.0-5.20 |

| Cr | 0.05-0.25 | 0.25 |

| Zr | - | - |

| Zn | 0.25 | 0.40 |

| Ti | 0.15 | 0.15 |

| Al | Remainder | Remainder |

Property of 5083 5383 aluminum square bar

| Alloy | Temper | Inscribed circle diameter of square bar /mm | Tension Strength /(N/mm2) | Yield Strength/(N/mm2) | Elongation /% | |

| A | A50 mm | |||||

| Not less than | ||||||

| 5083 | O | ≤12.50 | 270-350 | 110 | - | 14 |

| >12.50-200.00 | 270 | 12 | - | |||

| H112 | ≤12.50 | 270 | 125 | - | 12 | |

| >12.50-200.00 | 12 | - | ||||

| 5383 | O | ≤12.50 | 290 | 145 | - | 17 |

| >12.50-50.00 | 17 | - | ||||

| H112 | ≤12.50 | 310 | 190 | - | 13 | |

| >12.50-50.00 | 13 | - | ||||

Dimension tolerance of 5083 5383 aluminum square bar

Dimensional Tolerances for 5083 and 5383 Aluminum Square Bars

| Tolerance Item | Standard Tolerance | High Precision Tolerance |

| Side Length ≤ 50mm | ±0.40mm | ±0.25mm |

| Side Length > 50mm | ±0.50mm | ±0.30mm |

| Straightness | 3mm/m | 2mm/m |

| Angular Tolerance | ±0.5° | ±0.3° |

| Corner Radius | 2.0-3.0mm | 1.5-2.5mm |

- Straightness The standard straightness requirement is 3mm/m. However, for special applications such as marine use, some suppliers offer tighter control.

- Angular Tolerance The right angle deviation of square bars is usually controlled within ±0.5° to ensure geometric accuracy.

- Corner Radius The corner radius tolerance is generally between 2.0mm and 3.0mm, depending on the product dimensions.

Comparison of Different Standard Tolerances

The following table compares the tolerances of 5083 and 5383 aluminum square bars under different standards:

| Tolerance Item | ISO 6362-5:2022 | ASTM B221-21 | High Precision Standard |

| Side Length ≤ 50mm | ±0.40mm | ±0.50mm | ±0.25mm |

| Side Length > 50mm | ±0.50mm | ±0.60mm | ±0.30mm |

| Straightness | 3mm/m | 4mm/m | 2mm/m |

| Corner Radius | 2.0-3.0mm | 2.0-3.5mm | 1.5-2.5mm |

5083 5383 aluminum square bar stock list

| Description | Imperial Size (inch x inch) | Available Temper Conditions | Form |

| 5083 Extruded Aluminum Square Bar 0.500" x 0.500" | 0.500" x 0.500" | H111, H112, O | Square Bar |

| 5083 Extruded Aluminum Square Bar 0.750" x 0.750" | 0.750" x 0.750" | H111, H112, O | Square Bar |

| 5083 Extruded Aluminum Square Bar 1.000" x 1.000" | 1.000" x 1.000" | H111, H112, O | Square Bar |

| 5083 Extruded Aluminum Square Bar 1.250" x 1.250" | 1.250" x 1.250" | H111, H112, O | Square Bar |

| 5083 Extruded Aluminum Square Bar 1.500" x 1.500" | 1.500" x 1.500" | H111, H112, O | Square Bar |

| 5083 Extruded Aluminum Square Bar 2.000" x 2.000" | 2.000" x 2.000" | H111, H112, O | Square Bar |

| 5083 Extruded Aluminum Square Bar 2.500" x 2.500" | 2.500" x 2.500" | H111, H112, O | Square Bar |

| 5083 Extruded Aluminum Square Bar 3.000" x 3.000" | 3.000" x 3.000" | H111, H112, O | Square Bar |

| 5083 Extruded Aluminum Square Bar 4.000" x 4.000" | 4.000" x 4.000" | H111, H112, O | Square Bar |

| 5083 Extruded Aluminum Square Bar 5.000" x 5.000" | 5.000" x 5.000" | H112, O(Used for large sizes) | Square Bar |

| 5083 Extruded Aluminum Square Bar 6.000" x 6.000" | 6.000" x 6.000" | H112, O(For heavy load structure) | Square Bar |

5083 5383 aluminum square bar stock list

| Description | Size in. | Standard Length ft. | Temper | Form |

| 1/2" 5083/5383 Aluminum Square Bar | 1/2" | 12' Standard Length(Cut to length by request) | O/H111/H321/H116 | Square Bar |

| 5/8" 5083/5383 Aluminum Square Bar | 5/8" | 12' Standard Length(Cut to length by request) | O/H111/H321/H116 | Square Bar |

| 3/4" 5083/5383 Aluminum Square Bar | 3/4" | 12' Standard Length(Cut to length by request) | O/H111/H321/H116 | Square Bar |

| 1" 5083/5383 Aluminum Square Bar | 1" | 12' Standard Length(Cut to length by request) | O/H111/H321/H116 | Square Bar |

| 1 - 1/4" 5083/5383 Aluminum Square Bar | 1 - 1/4" | 12' Standard Length(Cut to length by request) | O/H111/H321/H116 | Square Bar |

| 1 - 1/2" 5083/5383 Aluminum Square Bar | 1 - 1/2" | 12' Standard Length(Cut to length by request) | O/H111/H321/H116 | Square Bar |

| 2" 5083/5383 Aluminum Square Bar | 2" | 12' Standard Length(Cut to length by request) | O/H111/H321/H116 | Square Bar |

| 2 - 1/2" 5083/5383 Aluminum Square Bar | 2 - 1/2" | 12' Standard Length(Cut to length by request) | O/H111/H321/H116 | Square Bar |

| 3" 5083/5383 Aluminum Square Bar | 3" | 12' Standard Length(Cut to length by request) | O/H111/H321/H116 | Square Bar |

| 4" 5083/5383 Aluminum Square Bar | 4" | 12' Standard Length(Cut to length by request) | O/H111/H321/H116 | Square Bar |

| 5" 5083/5383 Aluminum Square Bar | 5" | 12' Standard Length(Cut to length by request) | O/H111/H321/H116 | Square Bar |

| 6" 5083/5383 Aluminum Square Bar | 6" | 12' Standard Length(Cut to length by request) | O/H111/H321/H116 | Square Bar |

Material Characteristics of 5083 and 5383 Aluminum Square Bars

Comparison of 5083 and 5383 Material Properties

Below is a comparison of the main characteristics of 5083 and 5383 aluminum square bars:

| Property | 5083 Aluminum Square Bar | 5383 Aluminum Square Bar |

| Main Alloying Elements | Magnesium (4.0-4.9%), Manganese (0.40-1.0%) | Magnesium (4.0-4.9%), Manganese (0.40-1.0%), Zirconium |

| Tensile Strength | ≥270MPa | ≥275MPa |

| Yield Strength | ≥110MPa | ≥125MPa |

| Elongation | ≥20% | ≥16% |

| Hardness | Lower | About 10% higher than 5083 |

| Weldability | Excellent | Excellent, with a 15% increase in yield strength of welded structures |

| Corrosion Resistance | Excellent | Superior, especially in saltwater environments |

Material Characteristics of 5083 Aluminum Square Bar

The 5083 aluminum square bar belongs to the Al-Mg alloy series and has the following notable features:

Chemical Composition

The main alloying elements are magnesium (4.0-4.9%), manganese (0.40-1.0%), and chromium (0.05-0.25%), with the balance being aluminum. This composition grants the material excellent corrosion resistance and weldability.

Density and Weight

The density is about 2.7g/cm³, significantly lower than steel, giving it a lightweight characteristic. This feature is especially important in shipbuilding and vehicle manufacturing, reducing structural weight and improving fuel efficiency.

Mechanical Properties

Typical mechanical properties of 5083 aluminum square bar are: tensile strength ≥270MPa, yield strength ≥110MPa, elongation ≥20%. These properties make it suitable for applications requiring medium strength and good toughness.

Corrosion Resistance

The 5083 alloy exhibits excellent corrosion resistance, particularly against atmospheric, fresh water, seawater, alcohol, gasoline, organic acids, and concentrated nitric acid corrosion. This makes it especially suitable for marine environments.

Low Temperature Performance

As temperature decreases, the tensile strength, yield strength, and elongation of 5083 alloy increase, providing good low-temperature toughness. This makes it suitable for applications in low-temperature environments.

Material Characteristics of 5383 Aluminum Square Bar

The 5383 aluminum square bar is an upgraded version of 5083, with the following features:

Chemical Composition

The main alloying elements are magnesium (4.0-4.9%), manganese (0.40-1.0%), and a small amount of zirconium, with the remainder aluminum. Compared to 5083, trace elements are added to improve the material's strength and hardness.

Mechanical Properties

Typical mechanical properties of 5383 aluminum square bar are: tensile strength ≥275MPa, yield strength ≥125MPa, elongation ≥16%. In H116 temper, tensile strength can reach ≥305MPa, yield strength ≥215MPa.

Corrosion Resistance

The 5383 alloy further improves corrosion resistance while maintaining the excellent corrosion resistance of 5083, especially in saltwater environments. This makes it an ideal material for marine applications.

Low Temperature Performance

The 5383 alloy maintains its strength even in extreme low-temperature environments, making it suitable for manufacturing low-temperature pressure vessels and storage tanks.

Applications of 5083 and 5383 Aluminum Square Bars in Shipbuilding

Applications in Ship Structural Components

5083 and 5383 aluminum square bars have extensive applications in shipbuilding, mainly including the following areas:

- Hull Structure 5083 and 5383 aluminum square bars are widely used to manufacture structural components such as keels, ribs, and frames of ships. These parts require materials with high strength and excellent corrosion resistance to withstand various stresses and seawater erosion during navigation.

- Deck Structure 5083 and 5383 aluminum square bars are commonly used to manufacture deck support structures and reinforcements. These parts need sufficient strength and stiffness to bear the weight of personnel and cargo, while also requiring good corrosion resistance to withstand seawater and marine environmental corrosion.

- Superstructure 5083 and 5383 aluminum square bars are also used to manufacture ship superstructures, such as wheelhouses and funnels. These parts require materials with good machinability and weldability to meet the manufacturing demands of complex structures.

Applications in Ship Systems

Besides structural components, 5083 and 5383 aluminum square bars are widely used in various ship systems:

- Ship piping systems: used to manufacture support structures for various ship piping systems, such as seawater pipes, freshwater pipes, fuel pipes, and ventilation ducts.

- Ship ventilation systems: used to manufacture structural components of ship ventilation systems, such as ventilation duct supports and ventilation port frames.

- Ship electrical systems: used to manufacture installation brackets and protective structures for ship electrical equipment.

- Ship refrigeration systems: used to manufacture structural components and supports for ship refrigeration systems.

Applications in Special Types of Ships

5083 and 5383 aluminum square bars also have important applications in some special types of ships:

- LNG Ships 5383 aluminum square bars are widely used in the manufacturing of LNG (Liquefied Natural Gas) carriers due to their ability to maintain good strength and toughness at low temperatures.

- High-Speed Ships 5083 and 5383 aluminum square bars are widely used in the construction of high-speed ships and motorboats due to their lightweight and high-strength characteristics.

- Offshore Engineering Vessels Used in structural components and equipment supports of offshore engineering vessels, such as drilling platform supply vessels and diving support vessels.

Advantages of 5083 and 5383 Aluminum Square Bars in Shipbuilding Applications

5083 and 5383 aluminum square bars offer the following advantages in shipbuilding applications:

- Lightweight: Aluminum density is about one-third that of steel. Using aluminum square bars can significantly reduce ship weight, improving fuel efficiency and load capacity.

- Excellent Corrosion Resistance: 5083 and 5383 alloys possess excellent seawater corrosion resistance, reducing ship maintenance costs and extending service life.

- Good Weldability: Both alloys have good weldability, simplifying ship manufacturing processes and improving production efficiency.

- Good Low Temperature Performance: They maintain good mechanical properties in low-temperature environments, making them especially suitable for LNG ships and polar vessels.

Considerations When Purchasing 5083 and 5383 Aluminum Square Bars

Material Specification Confirmation

When purchasing 5083 and 5383 aluminum square bars, it is necessary to first confirm the following specification parameters:

Cross-Section Dimensions

Clearly specify the required side length dimensions, tolerance requirements, and fillet radius parameters of the square bars. It is recommended to select appropriate tolerance grades based on usage requirements: generally, h11-h13 tolerance grades for machining purposes, and h8-h10 grades for precision machining.

Length Requirements

Determine the required length of the square bars, including single piece length and total quantity needed. For long-sized square bars, consider transportation and processing convenience.

Delivery Condition

Choose the appropriate delivery temper according to subsequent processing and usage needs, such as O (annealed), H112 (work hardened + partial annealed), H116 (work hardened + stabilized), or H321 (work hardened + partial annealed), etc.

Material Quality Verification

When purchasing 5083 and 5383 aluminum square bars, the following quality verifications should be conducted:

- Chemical Composition Verification: Require material certificates to confirm that the chemical composition meets the standard requirements of 5083 or 5383 alloys.

- Mechanical Properties Testing: Require mechanical performance test reports to confirm that tensile strength, yield strength, elongation, and other indicators meet standard requirements.

- Surface Quality Inspection: Check the square bar surface for defects such as cracks, bubbles, scratches, burrs, etc.

- Dimensional Accuracy Measurement: Use measuring tools to verify side length, length, straightness, and fillet radius of the square bars, ensuring compliance with tolerance requirements.

For marine and special industry applications, require suppliers to provide relevant certifications, such as classification society certifications from DNV, ABS, LR, CCS, etc.

Other Application Areas of 5083 and 5383 Aluminum Square Bars

Construction and Structural Applications

Besides shipbuilding, 5083 and 5383 aluminum square bars are widely used in construction and structural fields:

- Building Structural ComponentsCan be used to manufacture building roof structures, balcony supports, and stair railings. These parts require materials with good corrosion resistance and decorative properties.

- Curtain Wall StructuresCan be used to manufacture support structures and frames for building curtain walls. These parts require sufficient strength and stiffness, along with good weather resistance and aesthetic qualities.

Transportation Applications

5083 and 5383 aluminum square bars are also widely used in the transportation field:

- Rail Transit: used to manufacture vehicle body structures and interior decoration for subways, light rail, and high-speed trains.

- Automotive Manufacturing: used to manufacture automotive chassis structures, seat frames, and crash beams.

- Refrigerated Trucks and Tankers: used to manufacture structural components and supports.

- Container Manufacturing: used to manufacture container frames and support structures.

Energy and Chemical Applications

5083 and 5383 aluminum square bars also have important applications in the energy and chemical industries:

Pressure Vessels

Can be used to manufacture various pressure vessels and storage tanks, such as LNG tanks, compressed air tanks, and chemical raw material tanks.

Heat Exchangers

Can be used to manufacture structural parts and supports for heat exchangers. These parts require materials with good thermal conductivity and corrosion resistance.

Other Application Fields

5083 and 5383 aluminum square bars are also used in the following fields:

- Aerospace 5083 aluminum square bars can be used to manufacture non-load-bearing aircraft structural components and interior parts.

- Military Equipment Used to manufacture structural parts for military vehicles, armor, and weapon systems.

- Sports Equipment Used to manufacture structural parts for bicycles, skis, golf clubs, and other sports gear.

- Medical Equipment Used to manufacture structural parts and supports for medical devices.

Recommendations for Choosing 5083 and 5383 Aluminum Square Bars

Performance Comparison of 5083 and 5383 Aluminum Square Bars

| Performance Indicator | 5083 Aluminum Square Bar | 5383 Aluminum Square Bar | Advantage Analysis |

| Tensile Strength | ≥270MPa | ≥275MPa | Slightly higher for 5383 |

| Yield Strength | ≥110MPa | ≥125MPa | About 13.6% higher for 5383 |

| Elongation | ≥20% | ≥16% | Better for 5083 |

| Corrosion Resistance | Excellent | Superior, especially in saltwater environments | Better for 5383 |

| Weldability | Excellent | Excellent, with a 15% increase in yield strength of welded structures | Both have advantages |

| Low Temperature Performance | Good | Excellent, maintaining high strength even at extreme low temperatures | Better for 5383 |

| Cost | Lower | Higher | More economical for 5083 |

Recommendations for Application Scenario Selection of 5083 and 5383 Aluminum Square Bars

Marine Applications

- General ship structural components: 5083 aluminum square bars can be selected for better cost performance.

- High-speed vessels and large ships: It is recommended to choose 5383 aluminum square bars, whose higher strength and hardness can reduce structural weight and improve sailing speed.

- LNG ships and low-temperature environment applications: 5383 aluminum square bars should be chosen as they maintain good mechanical properties under extreme low temperatures.

Construction and Structural Applications

- General building structural components: 5083 aluminum square bars can be selected for better cost performance.

- High-rise buildings and large-span structures: it is recommended to choose 5383 aluminum square bars, whose higher strength can reduce component size and increase usable space.

- Buildings in coastal and humid environments: it is recommended to choose 5383 aluminum square bars, whose superior corrosion resistance can reduce maintenance costs.

Recommended for you

-

5083 5383 O H112 Marine Grade Aluminum Bars are certified by CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and their quality fully complies with world marine grade standards.

-

Specialized in producing 5083 aluminum bars, offering multiple tempers such as H112 and O, supporting custom machining with outer diameters ranging from Φ15mm to 450mm. Ample stock and fast delivery.

-

5083 aluminum round bar is a high-performance corrosion-resistant alloy primarily used in harsh environments, especially marine applications. This non-heat-treatable alloy achieves its mechanical properties through strain hardening. Common tempers include H111, H116, and H321.

-

The 5083 and 5383 aluminum hex bars produced by Haomei comply with multiple international and industry standards to ensure product quality and performance meet global application requirements.

Other content readers are interested in

-

5083 marine grade aluminium checkered tread plate sheet

5083 pattern aluminum plate is widely used in decoration, shipbuilding and construction fields. Aluminum pattern plate has good forming, drilling and welding capabilities, is easy to manufacture, and its raised diamond lug pattern provides good slip resistance.

-

5083 Marine Grade Aluminum Pipe Tube

5083 Marine Grade Aluminum Pipe is commonly used in various marine applications such as shipbuilding, ship construction, offshore platforms and marine structures.

-

5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum is an aluminum alloy specifically designed for use in marine environments. It is known for its excellent corrosion resistance and high strength, making it ideal for applications such as shipbuilding, hulls, offshore structures and other marine components.

-

5383 Marine Grade Aluminum Plate Sheet

5383 marine grade aluminum plate has excellent corrosion resistance and high strength. Aluminum alloy 5383 is commonly used in shipbuilding and other maritime structures where durability and resistance to salt water corrosion are critical.

-

5383 H112 aluminum is a corrosion-resistant, medium-strength alloy with excellent formability, making it ideal for marine applications. It is also cost-effective for structural components exposed to harsh environments.

-

5383-H321 aluminum has high strength and excellent corrosion resistance, making it suitable for high-load marine applications, especially in environments that require resistance to intergranular corrosion and exfoliation corrosion.

-

5383-H116 aluminum offers good corrosion resistance through specific heat treatment and cold working, making it suitable for light-load marine applications, especially for long-term use in seawater environments.

-

5383 H34 aluminum alloy is a high-strength aluminum alloy that has undergone strain hardening and stabilization treatments, offering excellent corrosion resistance and weldability. It is widely used in marine, transportation, and construction fields.

-

5383-H32 Aluminum is an aluminum alloy that has undergone strain hardening and stabilization treatment, belonging to the aluminum-magnesium alloy series. The "H32" temper indicates that the alloy has been strain-hardened through cold working and then stabilized by appropriate heat treatment, with strength lying between the annealed (O) and full-hard (H38) states.

-

5383-H111 aluminum alloy is a type of aluminum alloy, which undergoes specific heat treatment and mechanical processing to be in the H111 condition. This alloy is widely used in environments that require good corrosion resistance and moderate strength.

-

5383-O aluminum alloy is the annealed (O condition) version of 5383 aluminum. It belongs to the aluminum-magnesium alloy series and has excellent corrosion resistance, particularly outstanding in marine environments.

-

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications.

-

Our company offers 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV), featuring excellent corrosion resistance, weldability, and medium strength. They are widely used in ship decks, hull outer plates, LNG storage tanks, and other fields.

-

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

-

With 20 years of experience in marine-grade aluminum production, our products are all certified by classification societies (such as CCS, DNV, etc.), and we offer customized solutions upon request.

-

5083 aluminum alloy flat bar is a high-performance aluminum material with magnesium as the main alloying element, specially designed for harsh environments. It is widely used in shipbuilding, pressure vessels, rail transportation, and cryogenic engineering.

-

We specialize in the production of 5083 aluminum square tubes, supporting customization of outer diameter (10–2500mm), wall thickness (0.4–100mm), and length (5–2000mm). Certified by ISO, SGS, BV, and other international standards to ensure stable and reliable mechanical properties.

-

Specializing in the production of 5083 H131 aluminum plates, we offer customized production with thicknesses from 0.2 to 350mm and widths from 30 to 2600mm. Global export supported, original factory warranty, and 30-day delivery.

-

5083-H32 aluminum plate plays a key role in shipbuilding due to its excellent performance. Whether used for structural components in large vessels or critical parts of high-performance speedboats, it delivers reliable performance and long-term durability.

-

5083 O aluminum is a special state aluminum material based on 5083 aluminum alloy, formed through an annealing process.

-

5083-H22 is an aluminum-magnesium alloy plate, belonging to the 5xxx series of non-heat-treatable aluminum alloys.

-

5083 H34 is a strain-hardened and stabilized aluminum alloy in the 5000 series, known for its high strength, excellent corrosion resistance, and good weldability.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5454 aluminum alloy not only possesses excellent corrosion resistance, but its unique high-temperature stress resistance makes it irreplaceable in welded structures for ship fuel tanks and high-temperature environments.

-

6061 marine aluminum has good corrosion resistance, high strength, good machinability and welding performance, and is suitable for marine structural parts.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

More content of interest to readers

What is the difference between 5083 H111 and H116 aluminum? What is the difference between 5083 H116 and H321 aluminum? 5083-H321 Aluminum Properties What is marine grade 5083 Aluminium? What is the difference between 5083 H32 and H321? 5059 Aluminum vs. 5083 Aluminum 5383-O Aluminum vs. 5456-O Aluminum 5383-H32 Aluminum vs. 5456-H32 Aluminum 5383-H111 Aluminum vs. 5456-H111 Aluminum 5383-H116 Aluminum vs. 5383-H321 Aluminum 5383 Aluminum vs. 5456 Aluminum 5383-H112 Aluminum vs. 5456-H112 Aluminum 5083 vs 5052 Aluminum Sheets A Comprehensive Guide for Marine Uses Why 5083 Aluminum Plate is the Go-To Choice for Marine Applications 5383 Aluminum Hot Rolling Process Is 5083 aluminium marine-grade? 5086 and 5083 Aluminum Materials in Shipbuilding 5083 and 6061 Aluminum Alloys: Applications in the Marine Industry DNV Marine Aluminum Sheet 5083 5083 vs. 5059: Aluminum Alloy Selection in Shipbuilding 5083 vs 5383 Aluminum Alloys: Which is Better for Your Project? 5052 and 5083 aluminum characteristics in saltwater Applications of 5083 Aluminum Plate in Shipbuilding Classification society certified 5083 h321 aluminum plate Common marine aluminum plates 5083 5052 5083 h111 marine aluminum plate performance characteristics 5083 aluminum plate for yacht 5083 h112 aluminum plate for shipbuilding What are the common temper of 5083 aluminum plates for ships? 5083 Marine Aluminum Plate for LNG Storage Tanks Medium thickness aluminum plate 5083 for ship Advantages of 5083 H116 Aluminum in Shipbuilding Marine Grade Aluminum Plate: 5083 H111 VS 5083 H321 5083 5052 6082 6061 Aluminum sheet metal for boat building 5083 Marine aluminum plate for boat body

You might be interested in: Marine Grade Aluminum 5083 Marine Aluminum 5383 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum