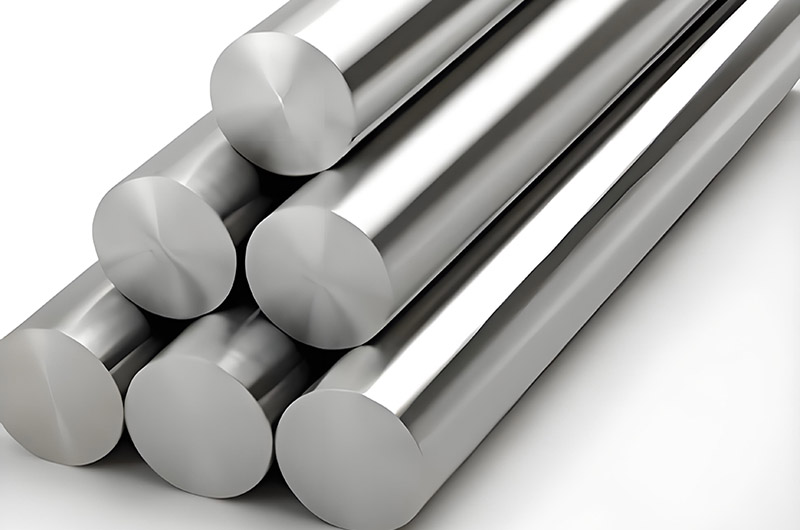

5083 Aluminum Round Bar

The 5083 aluminum round bar is a cylindrical aluminum product made from 5083 aluminum alloy. The H116 temper is specifically designed to optimize corrosion resistance in marine environments, while H321 provides stability in high-temperature environments.

5083 aluminum round bar is a high-performance, non-heat-treatable aluminum-magnesium alloy known for its excellent corrosion resistance, good strength-to-weight ratio, and outstanding weldability—qualities that make it the material of choice for demanding marine, cryogenic, and structural applications.

It contains 4.0–4.9% magnesium along with trace amounts of manganese and chromium, offering both strength and resistance to seawater and industrial chemicals. The ultimate tensile strength of the 5083 aluminum round bar reaches up to 390 MPa, and it maintains good toughness even at temperatures as low as -195°C, preserving mechanical integrity in extreme environments and during welding operations. It complies with major standards such as ASTM B221, ISO 6361-2, and AMS 4156, with diameters ranging from a few millimeters to over 600 mm, and is available with various surface and temper treatments.

5083 aluminum round bar is a high-performance corrosion-resistant alloy primarily used in harsh environments, especially marine applications. This non-heat-treatable alloy achieves its mechanical properties through strain hardening. Common tempers include H111, H116, and H321.

5083 Aluminum Round Bar Standards and Supply

| Specification | Description |

| Standards | ASTM B221 (Extruded Bar) |

| AMS 4095 | |

| Diameter Range | Varies from a few millimeters to several inches |

| Common range is 0.25 inches to 24.00 inches | |

| Supply Tempers | H111 (As-rolled) |

| H321 (Strain-hardened and stabilized) | |

| H116 (Corrosion-resistant temper) | |

| Length | Standard length is 12 to 20 feet (3.66 – 6.1 meters) |

| Custom cutting available | |

| Surface Treatment Options | Mill Finish |

| Polished | |

| Anodized | |

| Classification Society Certifications | Certified by the following international classification societies, ensuring compliance with global marine standards: |

| CCS (China Classification Society) | |

| DNV (Det Norske Veritas) | |

| NK (Nippon Kaiji Kyokai) | |

| ABS (American Bureau of Shipping) | |

| BV (Bureau Veritas) | |

| LR (Lloyd’s Register) | |

| KR (Korean Register) |

5083 Aluminum Round Bar Stock

| Description | Diameter (inches) | Form |

| 5083-H111 Extruded Bar 0.375″ Diameter | 0.375″ | Round Bar |

| 5083-H111 Extruded Bar 0.750″ Diameter | 0.750″ | Round Bar |

| 5083-H111 Extruded Bar 1.000″ Diameter | 1.000″ | Round Bar |

| 5083-H111 Extruded Bar 1.500″ Diameter | 1.500″ | Round Bar |

| 5083-H111 Extruded Bar 2.500″ Diameter | 2.500″ | Round Bar |

| 5083-H111 Extruded Bar 3.000″ Diameter | 3.000″ | Round Bar |

| 5083-H111 Extruded Bar 4.000″ Diameter | 4.000″ | Round Bar |

| 5083-H111 Extruded Bar 8.000″ Diameter | 8.000″ | Round Bar |

| 5083-H116 Extruded Bar 0.25" Diameter | 0.25" | Round Bar |

| 5083-H116 Extruded Bar 0.5" Diameter | 0.5" | Round Bar |

| 5083-H116 Extruded Bar 1" Diameter | 1" | Round Bar |

| 5083-H116 Extruded Bar 2" Diameter | 2" | Round Bar |

| 5083-H116 Extruded Bar 3" Diameter | 3" | Round Bar |

| 5083-H116 Extruded Bar 4" Diameter | 4" | Round Bar |

| 5083-H116 Extruded Bar 6" Diameter | 6" | Round Bar |

| 5083-H116 Extruded Bar 8" Diameter | 8" | Round Bar |

| 5083-H116 Extruded Bar 10" Diameter | 10" | Round Bar |

| 5083-H116 Extruded Bar 12" Diameter | 12" | Round Bar |

| 5083-H116 Extruded Bar 24" Diameter | 24" | Round Bar |

| 5083-H321 Extruded Bar 0.25" Diameter | 0.25" | Round Bar |

| 5083-H321 Extruded Bar 0.5" Diameter | 0.5" | Round Bar |

| 5083-H321 Extruded Bar 1" Diameter | 1" | Round Bar |

| 5083-H321 Extruded Bar 2" Diameter | 2" | Round Bar |

| 5083-H321 Extruded Bar 3" Diameter | 3" | Round Bar |

| 5083-H321 Extruded Bar 4" Diameter | 4" | Round Bar |

| 5083-H321 Extruded Bar 6" Diameter | 6" | Round Bar |

| 5083-H321 Extruded Bar 8" Diameter | 8" | Round Bar |

| 5083-H321 Extruded Bar 10" Diameter | 10" | Round Bar |

| 5083-H321 Extruded Bar 12" Diameter | 12" | Round Bar |

| 5083-H321 Extruded Bar 24" Diameter | 24" | Round Bar |

5083 Aluminum Round Bar Chemical Composition

Elemental Composition

- Magnesium (Mg): 4.0 – 4.9% — Provides solid solution strengthening and corrosion resistance.

- Manganese (Mn): 0.4 – 1.0% — Refines grain structure and increases strength.

- Chromium (Cr): 0.05 – 0.25% — Enhances corrosion resistance and controls recrystallization.

- Aluminum (Al): Balance (≈ 92.6 – 95.6%).

- Trace elements (Fe, Si, Cu, Ti, Zn) all below 0.40%, which contribute to overall material stability without affecting weldability.

5083 Aluminum Round Bar Mechanical Properties

Tensile Strength and Hardness

- Ultimate Tensile Strength (UTS): 290 – 390 MPa, depending on the temper (e.g., H111 vs H32).

- Yield Strength (0.2% offset): 110 – 340 MPa; lower in O temper, higher in H tempers.

- Brinell Hardness: 75 – 110 HB.

5083 Aluminum Round Bar Fatigue, Fracture Toughness, and Low-Temperature Performance

- Fatigue Strength: 93 – 190 MPa under rotating bending.

- Fracture Toughness: Excellent, suitable for welding and low-temperature applications.

- Low-Temperature Strengthening: When cooled to –195 °C, UTS increases by approximately 40%, yield strength increases by about 10%.

5083 Aluminum Round Bar Physical and Thermal Properties

Density and Conductivity

- Density: 2.66 g/cm³.

- Electrical Conductivity: 16 – 19 m/Ω·mm² (≈ 28–34 % IACS).

5083 Aluminum Round Bar Thermal Conductivity and Expansion

- Thermal Conductivity: Up to 140 W/m·K.

- Coefficient of Thermal Expansion: 22.3 – 26 × 10⁻⁶ K⁻¹ in the range of -50 °C to 300 °C.

5083 Aluminum Round Bar Corrosion Resistance and Weldability

Due to its high magnesium content, 5083 exhibits excellent resistance to seawater and industrial chemical corrosion. It maintains full strength after MIG, TIG, and friction stir welding, making it ideal for welded structures without requiring post-weld heat treatment.

5083 Aluminum Round Bar Tempers and Surface Treatments

- O (Annealed): Offers the best ductility and formability.

- H111, H32: Strain hardened and stabilized, balancing strength and ductility.

- Surface Treatments: Hot-rolled pickling, cold-drawn bright finish, centerless grinding, peeling, turned finish, or anodizing (to enhance surface protection).

Machinability and Secondary Processing

5083 has moderate machinability; sharp tools, rigid setups, and appropriate cutting fluids are recommended to minimize work hardening. In O temper, it responds well to cold bending, stamping, and hydroforming.

Applications of 5083 Aluminum Round Bar

| Diameter (inches) | Diameter (mm) | Typical Applications |

| 0.25" | 6.35 mm | Precision components, rivets |

| 0.5" | 12.7 mm | Small structural parts, hardware fittings |

| 1" | 25.4 mm | Marine riveting components, mechanical brackets |

| 2" | 50.8 mm | Vehicle frames, medium load-bearing structures |

| 3" | 76.2 mm | Pressure vessel supports, marine deck parts |

| 4" | 101.6 mm | Large welded structures, bridge components |

| 6" | 152.4 mm | Heavy-duty machinery shafts, ship keels |

| 8" | 203.2 mm | Industrial equipment bases, offshore platform structures |

| 10" | 254 mm | Reinforcing rings for storage tanks, port facilities |

| 12" | 304.8 mm | Extra-large pressure vessels, ship hull frameworks |

| 24" | 609.6 mm | Special engineering (e.g., deep-sea equipment, drilling platforms) |

Marine and Shipbuilding Industry

Due to its seawater resistance, it is the preferred choice for hulls, decks, and superstructures. Used for ship frameworks, bulkheads, and offshore platforms.

Aerospace and Cryogenic Engineering

Suitable for fuel tanks, cryogenic containers, and structural components, with increased strength at low temperatures.

Automotive and Transportation

Used in truck bodies, rail vehicles, trailers, and heavy-duty vehicle components to reduce weight and enhance durability.

Pressure Vessels and Structural Components

Used in pressure vessels, heat exchangers, and structural frames where corrosion resistance and weldability are critical.

Widely used in marine components (hulls, railings), transportation (truck bodies, rail vehicles), cryogenic storage, and pressure vessels. Its non-magnetic and recyclable nature meets sustainable and specialized industrial requirements.

Notes

- Processing Requirements: Heat treatment strengthening should be avoided; inert gas shielded welding methods are preferred.

- Storage Conditions: Recommended to store in a dry environment to prevent surface oxidation, which could affect subsequent polishing.

Recommended for you

-

5083 5383 O H112 Marine Grade Aluminum Bars are certified by CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and their quality fully complies with world marine grade standards.

-

Specialized in producing 5083 aluminum bars, offering multiple tempers such as H112 and O, supporting custom machining with outer diameters ranging from Φ15mm to 450mm. Ample stock and fast delivery.

-

The 5083 and 5383 aluminum hex bars produced by Haomei comply with multiple international and industry standards to ensure product quality and performance meet global application requirements.

-

Haomei Aluminum is capable of producing marine-grade 5083 and 5383 aluminum square bars in O and H112 tempers, certified by major international classification societies including DNV, NK, CCS, ABS, BV, LR, and KR.

Other content readers are interested in

-

5083 marine grade aluminium checkered tread plate sheet

5083 pattern aluminum plate is widely used in decoration, shipbuilding and construction fields. Aluminum pattern plate has good forming, drilling and welding capabilities, is easy to manufacture, and its raised diamond lug pattern provides good slip resistance.

-

5083 Marine Grade Aluminum Pipe Tube

5083 Marine Grade Aluminum Pipe is commonly used in various marine applications such as shipbuilding, ship construction, offshore platforms and marine structures.

-

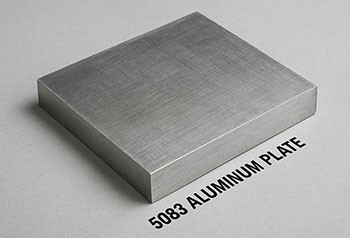

5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum is an aluminum alloy specifically designed for use in marine environments. It is known for its excellent corrosion resistance and high strength, making it ideal for applications such as shipbuilding, hulls, offshore structures and other marine components.

-

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications.

-

Our company offers 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV), featuring excellent corrosion resistance, weldability, and medium strength. They are widely used in ship decks, hull outer plates, LNG storage tanks, and other fields.

-

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

-

With 20 years of experience in marine-grade aluminum production, our products are all certified by classification societies (such as CCS, DNV, etc.), and we offer customized solutions upon request.

-

5083 aluminum alloy flat bar is a high-performance aluminum material with magnesium as the main alloying element, specially designed for harsh environments. It is widely used in shipbuilding, pressure vessels, rail transportation, and cryogenic engineering.

-

We specialize in the production of 5083 aluminum square tubes, supporting customization of outer diameter (10–2500mm), wall thickness (0.4–100mm), and length (5–2000mm). Certified by ISO, SGS, BV, and other international standards to ensure stable and reliable mechanical properties.

-

Specializing in the production of 5083 H131 aluminum plates, we offer customized production with thicknesses from 0.2 to 350mm and widths from 30 to 2600mm. Global export supported, original factory warranty, and 30-day delivery.

-

5083-H32 aluminum plate plays a key role in shipbuilding due to its excellent performance. Whether used for structural components in large vessels or critical parts of high-performance speedboats, it delivers reliable performance and long-term durability.

-

5083 O aluminum is a special state aluminum material based on 5083 aluminum alloy, formed through an annealing process.

-

5083-H22 is an aluminum-magnesium alloy plate, belonging to the 5xxx series of non-heat-treatable aluminum alloys.

-

5083 H34 is a strain-hardened and stabilized aluminum alloy in the 5000 series, known for its high strength, excellent corrosion resistance, and good weldability.

Recommended for you

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

-

5059 aluminum is both a high-magnesium and high-zinc alloy, offering excellent corrosion resistance and fire resistance.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

5383 aluminum offers excellent fatigue resistance and crack resistance, and its unique properties make it irreplaceable in the design of high-speed vessels and marine structures that require long-term fatigue resistance.

-

5754 aluminum is a medium-to-high strength alloy with excellent weldability, a low tendency for welding cracks, and high strength in both the weld joint and the crystalline metal.

-

5456 aluminum, with its unique high strength, exceptional fatigue resistance, and resistance to stress corrosion cracking, is irreplaceable in heavy-duty hull structures.

-

5454 aluminum alloy not only possesses excellent corrosion resistance, but its unique high-temperature stress resistance makes it irreplaceable in welded structures for ship fuel tanks and high-temperature environments.

-

6061 marine aluminum has good corrosion resistance, high strength, good machinability and welding performance, and is suitable for marine structural parts.

-

6082 has medium strength and good corrosion resistance, while being lightweight, making it an ideal material for manufacturing components of high-speed vessels.

More content of interest to readers

What is the difference between 5083 H111 and H116 aluminum? What is the difference between 5083 H116 and H321 aluminum? 5083-H321 Aluminum Properties What is marine grade 5083 Aluminium? What is the difference between 5083 H32 and H321? 5059 Aluminum vs. 5083 Aluminum 5083 vs 5052 Aluminum Sheets A Comprehensive Guide for Marine Uses Why 5083 Aluminum Plate is the Go-To Choice for Marine Applications Is 5083 aluminium marine-grade? 5086 and 5083 Aluminum Materials in Shipbuilding 5083 and 6061 Aluminum Alloys: Applications in the Marine Industry DNV Marine Aluminum Sheet 5083 5083 vs. 5059: Aluminum Alloy Selection in Shipbuilding 5083 vs 5383 Aluminum Alloys: Which is Better for Your Project? 5052 and 5083 aluminum characteristics in saltwater Applications of 5083 Aluminum Plate in Shipbuilding Classification society certified 5083 h321 aluminum plate Common marine aluminum plates 5083 5052 5083 h111 marine aluminum plate performance characteristics 5083 aluminum plate for yacht 5083 h112 aluminum plate for shipbuilding What are the common temper of 5083 aluminum plates for ships? 5083 Marine Aluminum Plate for LNG Storage Tanks Medium thickness aluminum plate 5083 for ship Advantages of 5083 H116 Aluminum in Shipbuilding Marine Grade Aluminum Plate: 5083 H111 VS 5083 H321 5083 5052 6082 6061 Aluminum sheet metal for boat building 5083 Marine aluminum plate for boat body

You might be interested in: Marine Grade Aluminum 5083 Marine Aluminum 5083 h321 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum