5083 Aluminum Square Tubes

The 5083 aluminum square tube is a tubular profile with a square cross-section made from 5083 aluminum alloy, an important member of the Al-Mg anti-rust aluminum alloy family.

5083 aluminum square tube is an extruded structural profile made from AA5083. AA5083 is a non-heat-treatable aluminum-magnesium alloy known for its outstanding corrosion resistance, high strength, and excellent weldability. Its square cross-section provides uniform load-bearing capacity in multiple directions, making it ideal for demanding applications in marine, transportation, and industrial sectors.

The composition of the 5083 alloy includes approximately 4–4.9% magnesium, 0.4–1% manganese, and trace amounts of chromium, giving it both toughness and formability, with better performance in corrosive environments than many other 5000-series alloys. The square tube form retains these inherent material properties while offering geometric advantages of hollow profiles, such as lighter weight and lower cost compared to solid bars.

Haomei Aluminum specializes in the production of 5083 aluminum square tubes, using high-magnesium alloy materials with excellent seawater corrosion resistance and weldability. Widely used in shipbuilding, pressure vessels, rail transit, and other fields. Products support customization of outer diameter (10–2500mm), wall thickness (0.4–100mm), and length (5–2000mm), and offer diverse surface treatments such as anodizing, brushing, and polishing. Certified by ISO, SGS, BV, and other international standards to ensure stable and reliable mechanical properties. OEM processing (cutting, bending, welding) supported, with fast delivery in 7–15 days and direct global port logistics. Ample stock available with free sample testing to meet your engineering and industrial needs.

5083 Aluminum Square Tubes Processing Properties

- Weldability: Excellent arc welding performance, suitable for complex structural welding

- Formability: Good cold working properties, can be formed through extrusion and deep drawing processes

- Surface Treatment: Aesthetic appearance after anodizing, excellent polishing effect

5083 Aluminum Square Tubes Standards and Specifications

- EN 755-2 / EN ISO 6361: European standards covering mechanical and chemical requirements for extruded and cold-processed products

- ASTM B221: Specification for aluminum and aluminum alloy extruded bars, rods, wires, profiles, and tubes

- ISO 6362-2: International standard for extruded aluminum profiles ensuring dimensional tolerance and quality control

5083 Aluminum Square Tubes Key Advantages

- Corrosion Resistance: Outstanding performance in marine atmospheres and industrial environments, especially suitable for seawater conditions

- Lightweight Characteristics: Density of approximately 2.7g/cm³, about 65% lighter than steel, suitable for weight-sensitive applications

Haomei 5083 Aluminum Square Tube Stock

| Description | Side Length, in | Wall Thickness, in |

| 5083-H111 Extruded Square Tube 0.500" x 0.500" | 0.500" | 0.062″ |

| 5083-H111 Extruded Square Tube 0.500" x 0.500" | 0.500" | 0.125″ |

| 5083-H111 Extruded Square Tube 0.500" x 0.500" | 0.500" | 0.188″ |

| 5083-H111 Extruded Square Tube 0.500" x 0.500" | 0.500" | 0.250″ |

| 5083-H111 Extruded Square Tube 0.500" x 0.500" | 0.500" | 0.375″ |

| 5083-H111 Extruded Square Tube 0.750" x 0.750" | 0.750" | 0.062″ |

| 5083-H111 Extruded Square Tube 0.750" x 0.750" | 0.750" | 0.125″ |

| 5083-H111 Extruded Square Tube 0.750" x 0.750" | 0.750" | 0.188″ |

| 5083-H111 Extruded Square Tube 0.750" x 0.750" | 0.750" | 0.250″ |

| 5083-H111 Extruded Square Tube 0.750" x 0.750" | 0.750" | 0.375″ |

| 5083-H111 Extruded Square Tube 1.000" x 1.000" | 1.000" | 0.062″ |

| 5083-H111 Extruded Square Tube 1.000" x 1.000" | 1.000" | 0.125″ |

| 5083-H111 Extruded Square Tube 1.000" x 1.000" | 1.000" | 0.188″ |

| 5083-H111 Extruded Square Tube 1.000" x 1.000" | 1.000" | 0.250″ |

| 5083-H111 Extruded Square Tube 1.000" x 1.000" | 1.000" | 0.375″ |

| 5083-H111 Extruded Square Tube 1.500" x 1.500" | 1.500" | 0.062″ |

| 5083-H111 Extruded Square Tube 1.500" x 1.500" | 1.500" | 0.125″ |

| 5083-H111 Extruded Square Tube 1.500" x 1.500" | 1.500" | 0.188″ |

| 5083-H111 Extruded Square Tube 1.500" x 1.500" | 1.500" | 0.250″ |

| 5083-H111 Extruded Square Tube 1.500" x 1.500" | 1.500" | 0.375″ |

| 5083-H111 Extruded Square Tube 2.000" x 2.000" | 2.000" | 0.062″ |

| 5083-H111 Extruded Square Tube 2.000" x 2.000" | 2.000" | 0.125″ |

| 5083-H111 Extruded Square Tube 2.000" x 2.000" | 2.000" | 0.188″ |

| 5083-H111 Extruded Square Tube 2.000" x 2.000" | 2.000" | 0.250″ |

| 5083-H111 Extruded Square Tube 2.000" x 2.000" | 2.000" | 0.375″ |

| 5083-H111 Extruded Square Tube 2.500" x 2.500" | 2.500" | 0.062″ |

| 5083-H111 Extruded Square Tube 2.500" x 2.500" | 2.500" | 0.125″ |

| 5083-H111 Extruded Square Tube 2.500" x 2.500" | 2.500" | 0.188″ |

| 5083-H111 Extruded Square Tube 2.500" x 2.500" | 2.500" | 0.250″ |

| 5083-H111 Extruded Square Tube 2.500" x 2.500" | 2.500" | 0.375″ |

| 5083-H111 Extruded Square Tube 3.000" x 3.000" | 3.000" | 0.062″ |

| 5083-H111 Extruded Square Tube 3.000" x 3.000" | 3.000" | 0.125″ |

| 5083-H111 Extruded Square Tube 3.000" x 3.000" | 3.000" | 0.188″ |

| 5083-H111 Extruded Square Tube 3.000" x 3.000" | 3.000" | 0.250″ |

| 5083-H111 Extruded Square Tube 3.000" x 3.000" | 3.000" | 0.375″ |

| 5083-H111 Extruded Square Tube 4.000" x 4.000" | 4.000" | 0.062″ |

| 5083-H111 Extruded Square Tube 4.000" x 4.000" | 4.000" | 0.125″ |

| 5083-H111 Extruded Square Tube 4.000" x 4.000" | 4.000" | 0.188″ |

| 5083-H111 Extruded Square Tube 4.000" x 4.000" | 4.000" | 0.250″ |

| 5083-H111 Extruded Square Tube 4.000" x 4.000" | 4.000" | 0.375″ |

| 5083-H111 Extruded Square Tube 5.000" x 5.000" | 5.000" | 0.062″ |

| 5083-H111 Extruded Square Tube 5.000" x 5.000" | 5.000" | 0.125″ |

| 5083-H111 Extruded Square Tube 5.000" x 5.000" | 5.000" | 0.188″ |

| 5083-H111 Extruded Square Tube 5.000" x 5.000" | 5.000" | 0.250″ |

| 5083-H111 Extruded Square Tube 5.000" x 5.000" | 5.000" | 0.375″ |

| 5083-H111 Extruded Square Tube 6.000" x 6.000" | 6.000" | 0.062″ |

| 5083-H111 Extruded Square Tube 6.000" x 6.000" | 6.000" | 0.125″ |

| 5083-H111 Extruded Square Tube 6.000" x 6.000" | 6.000" | 0.188″ |

| 5083-H111 Extruded Square Tube 6.000" x 6.000" | 6.000" | 0.250″ |

| 5083-H111 Extruded Square Tube 6.000" x 6.000" | 6.000" | 0.375″ |

5083 Aluminum Square Tubes Alloying Elements

- Magnesium (Mg): 4.0–4.9%, provides primary strengthening through solid solution strengthening

- Manganese (Mn): ≤ 1.0%, improves toughness and controls grain structure

- Chromium (Cr): ≤ 0.25%, enhances corrosion resistance and inhibits grain growth during welding

- Other elements (Silicon, Iron, Zinc, Titanium): each ≤ 0.4%, balance strength, formability, and corrosion resistance

5083 Aluminum Square Tubes Classification

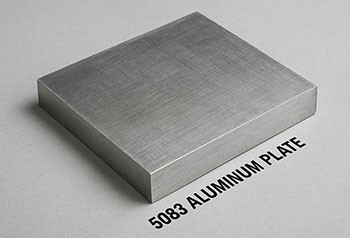

- Grade: AA5083 (UNS A95083, ISO AlMg4.5Mn)

- Tempers: Commonly O, H111, H116, H321, and H131; H321 (strain hardened and stabilized) is often used for extruded tubes to optimize ductility and strength

5083 Aluminum Square Tubes Physical Properties

- Density: 2.65 g/cm³, enables lightweight yet strong structures

- Melting Range: Approx. 570 °C, suitable for hot working and welding operations

- Elastic Modulus: ~72 GPa, provides good rigidity for structural applications

5083 Aluminum Square Tubes Mechanical Properties (Typical values in H111 temper)

- Ultimate Tensile Strength (Rm): 275–317 MPa

- Yield Strength (Rp0.2): ≥ 228 MPa

- Elongation: ≥ 10–12% over 50 mm gauge length, balancing strength and formability

- Hardness (HBW): Up to 70, indicating moderate work hardening capacity

5083 Aluminum Square Tubes Manufacturing and Welding

- Extrusion: Square tubes are produced via direct or indirect extrusion processes at temperatures above recrystallization, then cooled and straightened to strict tolerances.

- Weldability: Suitable for MIG, TIG, and resistance welding; post-weld strength retention exceeds 90%, with no hot cracking

- Machinability: Moderate to poor; best practices include using sharp tools and ample coolant to prevent work hardening and surface wear

5083 Aluminum Square Tubes Surface Treatment and Finishing

- Anodizing: Anodizing can enhance corrosion resistance and appearance; thickness and color uniformity depend on alloy impurities

- Painting and Coating: Typically powder coating or painting is used to provide additional protection in harsh industrial or marine environments; surface pretreatments (e.g., chromate conversion) enhance adhesion

Typical Applications of 5083 Aluminum Square Tubes

| Application Field | Specific Use |

| Shipbuilding | Hull structures, deck supports, gangway frames |

| Rail Transit | Subway and light rail car frames, roof fairing support structures |

| Pressure Vessels | Reinforcement ribs for LNG transport tanks, refrigerated container frames |

| Architectural Decoration | Curtain wall keels, sunroom support structures, corrosion-resistant canopy frames |

| Military Equipment | Support structures for missile launch racks, lightweight components for armored vehicles |

- Marine Structures: Hulls, decks, and superstructures; square tubes are used as framing components, supports, and struts due to their excellent seawater resistance.

- Pressure Vessels and Cryogenic Engineering: Frames and supports in cryogenic tanks and industrial rigs, maintaining high strength at sub-zero temperatures.

- Transportation: Bodies of rail vehicles, truck frames, and trailer understructures; the tubular geometry reduces weight and improves fuel efficiency.

- Construction and Decoration: Structural frames for exterior walls, pavilions, and canopies; anodizing or painting ensures both durability and aesthetics.

5083 Aluminum Square Tubes Manufacturing Process

Extrusion Forming

Hot extrusion is used to process aluminum billets into square tube blanks, with a typical annealing temperature of 415°C.

Cold Work Hardening

Cold drawing processes are applied to control dimensional accuracy and enhance surface finish.

Finishing Treatments

Includes straightening, cutting (standard fixed length of 2500 mm), and surface passivation processes.

5083 aluminum square tubes combine the material advantages of AA5083 alloy with the structural benefits of hollow square profiles, making them a versatile solution for corrosive, marine, and high-strength applications. The balance of strength, weldability, and corrosion resistance ensures long-term performance in industrial and architectural fields.

Recommended for you

-

5083 Marine Grade Aluminum Pipe is commonly used in various marine applications such as shipbuilding, ship construction, offshore platforms and marine structures.

Other content readers are interested in

-

5083 marine grade aluminium checkered tread plate sheet

5083 pattern aluminum plate is widely used in decoration, shipbuilding and construction fields. Aluminum pattern plate has good forming, drilling and welding capabilities, is easy to manufacture, and its raised diamond lug pattern provides good slip resistance.

-

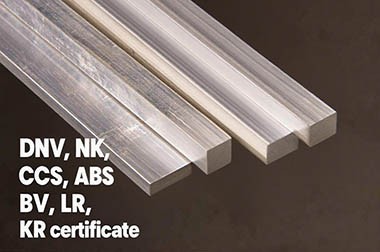

5083 5383 O H112 Marine Grade Aluminum Bars

5083 5383 O H112 Marine Grade Aluminum Bars are certified by CCS, DNV, NK, CCS, ABS, BV, LR, KR and other classification societies, and their quality fully complies with world marine grade standards.

-

5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum is an aluminum alloy specifically designed for use in marine environments. It is known for its excellent corrosion resistance and high strength, making it ideal for applications such as shipbuilding, hulls, offshore structures and other marine components.

-

As a trusted aluminum plate manufacturer, we specialize in producing high-quality 5083 H321 aluminum plates suitable for marine, transportation, and industrial applications.

-

Our company offers 5083-H116 aluminum plates certified by classification societies (CCS/BV/DNV), featuring excellent corrosion resistance, weldability, and medium strength. They are widely used in ship decks, hull outer plates, LNG storage tanks, and other fields.

-

5083-H111 aluminum is a non-heat-treatable strain-hardened aluminum-magnesium alloy, known for its exceptional corrosion resistance in marine and industrial environments and its ability to maintain high strength even after welding.

-

With 20 years of experience in marine-grade aluminum production, our products are all certified by classification societies (such as CCS, DNV, etc.), and we offer customized solutions upon request.

-

5083 aluminum alloy flat bar is a high-performance aluminum material with magnesium as the main alloying element, specially designed for harsh environments. It is widely used in shipbuilding, pressure vessels, rail transportation, and cryogenic engineering.

-

Specialized in producing 5083 aluminum bars, offering multiple tempers such as H112 and O, supporting custom machining with outer diameters ranging from Φ15mm to 450mm. Ample stock and fast delivery.

-

5083 aluminum round bar is a high-performance corrosion-resistant alloy primarily used in harsh environments, especially marine applications. This non-heat-treatable alloy achieves its mechanical properties through strain hardening. Common tempers include H111, H116, and H321.

-

Specializing in the production of 5083 H131 aluminum plates, we offer customized production with thicknesses from 0.2 to 350mm and widths from 30 to 2600mm. Global export supported, original factory warranty, and 30-day delivery.

-

5083-H32 aluminum plate plays a key role in shipbuilding due to its excellent performance. Whether used for structural components in large vessels or critical parts of high-performance speedboats, it delivers reliable performance and long-term durability.

-

5083 O aluminum is a special state aluminum material based on 5083 aluminum alloy, formed through an annealing process.

-

5083-H22 is an aluminum-magnesium alloy plate, belonging to the 5xxx series of non-heat-treatable aluminum alloys.

-

5083 H34 is a strain-hardened and stabilized aluminum alloy in the 5000 series, known for its high strength, excellent corrosion resistance, and good weldability.

-

5083 5383 Marine Grade Aluminium Hex Bar

The 5083 and 5383 aluminum hex bars produced by Haomei comply with multiple international and industry standards to ensure product quality and performance meet global application requirements.

-

5083 5383 O H112 Marine Aluminum Square Bar

Haomei Aluminum is capable of producing marine-grade 5083 and 5383 aluminum square bars in O and H112 tempers, certified by major international classification societies including DNV, NK, CCS, ABS, BV, LR, and KR.

Recommended for you

-

5083 is basically used to manufacture ship hulls because of its relatively high strength and good corrosion resistance.

-

6061 marine aluminum has good corrosion resistance, high strength, good machinability and welding performance, and is suitable for marine structural parts.

-

5086 aluminum alloy is irreplaceable in hull and deck applications in marine operating environments due to its unique seawater corrosion resistance, excellent low-temperature toughness, and good weldability.

-

5052 marine aluminum alloy is a high-strength, corrosion-resistant, easy-to-process and weld aluminum alloy, which is widely used in the manufacture of ships and marine structures.

More content of interest to readers

What is the difference between 5083 H111 and H116 aluminum? What is the difference between 5083 H116 and H321 aluminum? 5083-H321 Aluminum Properties What is marine grade 5083 Aluminium? What is the difference between 5083 H32 and H321? 5059 Aluminum vs. 5083 Aluminum 5083 vs 5052 Aluminum Sheets A Comprehensive Guide for Marine Uses Why 5083 Aluminum Plate is the Go-To Choice for Marine Applications Is 5083 aluminium marine-grade? 5086 and 5083 Aluminum Materials in Shipbuilding 5083 and 6061 Aluminum Alloys: Applications in the Marine Industry DNV Marine Aluminum Sheet 5083 5083 vs. 5059: Aluminum Alloy Selection in Shipbuilding 5083 vs 5383 Aluminum Alloys: Which is Better for Your Project? 5052 and 5083 aluminum characteristics in saltwater Applications of 5083 Aluminum Plate in Shipbuilding Classification society certified 5083 h321 aluminum plate Common marine aluminum plates 5083 5052 5083 h111 marine aluminum plate performance characteristics 5083 aluminum plate for yacht 5083 h112 aluminum plate for shipbuilding What are the common temper of 5083 aluminum plates for ships? 5083 Marine Aluminum Plate for LNG Storage Tanks Medium thickness aluminum plate 5083 for ship Advantages of 5083 H116 Aluminum in Shipbuilding Marine Grade Aluminum Plate: 5083 H111 VS 5083 H321 5083 5052 6082 6061 Aluminum sheet metal for boat building 5083 Marine aluminum plate for boat body

You might be interested in: Marine Grade Aluminum 5083 Marine Aluminum 5083 h321 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum