What is the difference between 5083 H111 and H116 aluminum?

Last Updated :

The primary difference between 5083 H111 and 5083-H116 aluminum lies in their tempering processes, which lead to different mechanical properties and suitability for various applications.

The difference between 5083 H111 and 5083-H116 aluminum alloys lies in their mechanical properties, processing methods, and application suitability. Both belong to the 5083 series, a marine-grade aluminum-magnesium alloy known for its excellent corrosion resistance and weldability, but their temper states (H111 vs. H116) determine their performance characteristics.

Choosing H111 provides a cost-effective and easily formable solution for mild environments, while H116 is suitable for high-strength, corrosion-resistant applications in marine or extreme conditions. The choice of material depends on a balance between strength requirements, environmental exposure, and manufacturing needs.

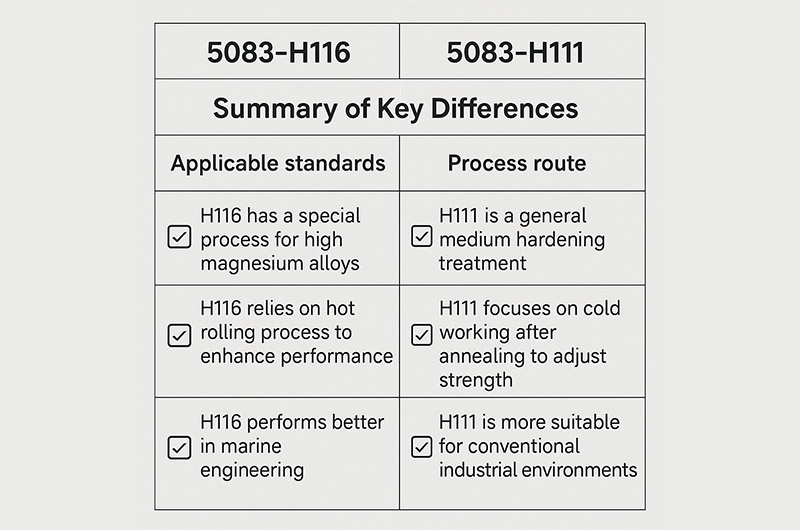

Key Differences Between 5083 H116 and H111

- Applicable Standards: H116 is processed under special procedures for high-magnesium alloys, whereas H111 is a general-purpose, moderately hardened treatment.

- Processing Route: H116 relies on hot rolling to enhance performance, while H111 emphasizes cold working after annealing to control strength.

- Application Scenarios: H116 performs better in marine engineering, while H111 is more suitable for conventional industrial environments.

Comparison of Mechanical Properties and Characteristics of 5083 H116 and H111

| Characteristics | H111 Aluminum Plate | H116 Aluminum Plate |

| Strength | Medium strength, suitable for general structural components | Higher strength, meets heavy-duty requirements such as in shipbuilding |

| Corrosion Resistance | Excellent, suitable for industrial atmospheric environments | Superior, specially designed for marine environments |

| Weldability | Excellent, suitable for complex welded structures | Better crack resistance during welding, suitable for high-magnesium alloy welding |

| Workability | Good cold workability, suitable for forming processes | Requires coordination with hot rolling, higher degree of work hardening |

5083 H116 vs H111 Tempering Processes

- H111 Temper: This condition involves minimal strain hardening, achieved through slight cold working after annealing. It imparts moderate strength while maintaining good formability.

- H116 Temper: This condition is the result of strain hardening and is specifically designed for marine applications. It includes stringent controls to ensure enhanced corrosion resistance and mechanical strength.

| Characteristics/Temper | 5083 H111 | 5083 H116 |

| Processing Temper Description | Slightly work-hardened after annealing | Controlled work hardening + stabilization heat treatment |

| Balance of Strength and Ductility | Good ductility with moderately enhanced strength | Higher strength while maintaining a certain level of ductility |

| Suitable Applications | General manufacturing uses such as low-stress containers and structural components | Specifically designed for marine applications such as hulls, decks, and pontoons |

| Stress Corrosion Cracking Resistance (SCC) | General level | Optimized processing to significantly improve SCC resistance |

| Microstructure Control | Relatively loose control requirements | Magnesium content and microstructure are more strictly controlled to ensure corrosion resistance |

| Mechanical Property Specifications | Not restricted by strict mechanical property standards | Meets specific mechanical and corrosion resistance standards |

| Typical Application Fields | Storage tanks, welded structures, automotive panels, etc. | Hull structures, marine platforms, ship exteriors, watercraft |

| Corrosion Resistance | Excellent | Superior, especially stronger resistance to seawater corrosion |

| Standard References | ASTM B209, B210, B221, etc. (temper not strictly defined) | Typically refers to ASTM B928 (specifically for H116 and marine-grade aluminum plates) |

5083 H116 vs H111 Mechanical Properties Comparison

| Property | 5083-H111 | 5083-H116 |

| Ultimate Tensile Strength | 300 MPa | 320 MPa |

| Yield Strength | 150 MPa | 230 MPa |

| Brinell Hardness | 75 | 83 |

| Fatigue Strength | 120 MPa | 160 MPa |

| Elongation at Break | 13% | 12% |

5083 H116 vs H111 Corrosion Resistance

- 5083 H111: Offers good corrosion resistance, suitable for general environments.

- 5083 H116: Undergoes rigorous exfoliation and intergranular corrosion testing, making it an ideal choice for marine environments.

Both alloys resist seawater and marine atmospheric corrosion, but H116 is specifically designed to provide superior performance in harsh marine conditions. Its processing reduces susceptibility to exfoliation and stress corrosion cracking, which is crucial for offshore structures and hulls.

5083 H116 vs H111 Welding and Post-Weld Performance

- 5083 H111: Maintains good weldability with minimal strength loss in the heat-affected zone (HAZ), making it suitable for welded structures requiring ductility.

- 5083 H116: While welding reduces the HAZ strength to annealed (O temper) levels, the unaffected base material retains high strength, making it well-suited for marine applications where localized strength retention is critical.

5083 H116 vs H111 Applications

- H111: Suitable for applications requiring good formability and moderate strength, such as general structural components.

- H116: Preferred for marine applications like shipbuilding and offshore structures, where high strength and excellent corrosion resistance are essential.

| Characteristics / Temper | 5083 H111 | 5083 H116 |

| Processing Temper Description | Slightly work-hardened after annealing | Controlled work hardening and stabilization heat treatment |

| Balance of Strength and Ductility | Good ductility with moderately enhanced strength | Higher strength while maintaining a certain level of ductility |

| Corrosion Resistance | Good | Excellent, specifically optimized for marine environments |

| Stress Corrosion Cracking (SCC) Resistance | General | Optimized processing enhances SCC resistance |

| Microstructure Control | Relatively loose control requirements | Stricter control over magnesium content and microstructure |

| Mechanical Property Specifications | Not restricted by strict mechanical property standards | Meets specific mechanical and corrosion resistance standards (e.g., ASTM B928) |

| Applicable Standards | ASTM B209, B210, B221, etc. | ASTM B928 (specifically for aluminum plates in marine environments) |

| Typical Application Scenarios | General structures, such as vehicle panels, building frames, body manufacturing, industrial pedals, welded parts, and non-critical marine components where formability and weldability are prioritized. | Preferred material for marine and offshore applications like hulls, decks, offshore platforms, also commonly used in pressure vessels and cryogenic storage tanks, suitable for scenarios requiring high load-bearing capacity and exceptional resistance to marine corrosion. |

Although 5083-H111 and 5083-H116 share the same base alloy composition, their different tempering processes result in distinct mechanical properties and corrosion resistance. H111 is best suited for applications requiring good formability and moderate strength, while H116 is specifically designed for marine environments demanding higher strength and superior corrosion resistance.

Recommended Product: 5083 marine grade aluminium checkered tread plate sheet 5083 5383 O H112 Marine Grade Aluminum Bars 5083 Marine Grade Aluminum Pipe Tube 5083 Marine Grade Aluminum Plate Sheet 5083 H321 Aluminum Plate 5083 H116 Aluminum Plate Aluminium 5083 H111 Aluminum 5083 H112 5083 Aluminum Flat Bar 5083 Aluminum Bar 5083 Aluminum Round Bar 5083 Aluminum Square Tubes 5083 H131 Aluminum Plate 5083 H32 Aluminum Plate 5083 O Aluminum 5083 H22 5083 H34 5083 5383 Marine Grade Aluminium Hex Bar 5083 5383 O H112 Marine Aluminum Square Bar

You might be interested in: Marine Grade Aluminum 5083 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum