Aluminium Plate specifications for Ship Building

Last Updated :

Due to excellent performance, high strength, corrosion resistance, good welding and formability, it is widely used in different components and structures of the shipbuilding industry.

Each alloy finds appropriate applications in the shipbuilding industry based on its specific advantages to ensure the reliability and durability of the ship.

5083 O H116 H321 Aluminium Plate for Ship Building

The 5083 alloy has excellent corrosion resistance and high strength, which is especially suitable for the marine environment. Its corrosion resistance makes it very suitable for the parts such as hull, deck, and LNG storage tanks that need to be exposed in seawater for a long time. In addition, the good welding performance and high intensity of the alloy can still be maintained after welding, making it popular among the shipbuilding industry.

- Thickness: 0.15-500 mm

- Width: 20-2650 mm

- Level: 500-16000 mm

- Application: ship, LNG storage tank, gas tank, etc.

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 5083 O | 275-350 | 125 | 16-23 |

| 5083 H116 | 305 | 215 | 12 |

| 5083 H321 | 305 | 215 | 12 |

5052 H32 H34 Aluminium Plate for Ship Building

The 5052 alloy is known for its good formability and medium intensity, and it is suitable for the side plates, chimneys, keels and deck of ships. Its excellent corrosion resistance and weldability enable it to be used in the marine environment, and it also has good fatigue strength and antioxidant.

- Thickness: 0.15-600 mm

- Width: 20-2650 mm

- Level: 500-16000 mm

- Application: ship's side board, ship chimney, ship keel, ship deck, etc.

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 5052 H32 | 215-265 | 160 | 10-12 |

| 5052 H34 | 230-280 | 180 | 8-10 |

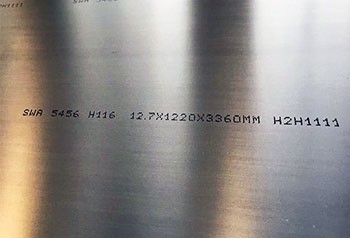

5086 H34 H111 Aluminium Plate for Ship Building

The 5086 alloy is widely used in the shipbuilding industry due to its high intensity and good corrosion resistance. Its good welding performance makes it suitable for manufacturing structural parts that need to be welded, such as hulls and deck. 5086 alloys can still maintain higher intensity after welding, which is an ideal choice for ship structures and fuel tanks.

- Thickness: 0.5-600 mm

- Width: 20-2650 mm

- Level: 500-16000 mm

- Applications: car, ship, fuel tank, etc.

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 5086 H32 | 275 | 215 | 14 |

| 5086 H34 | 305 | 240 | 12 |

| 5086 H111 | 275 | 125 | 14 |

5454 H32 H34 Aluminium Plate for Ship Building

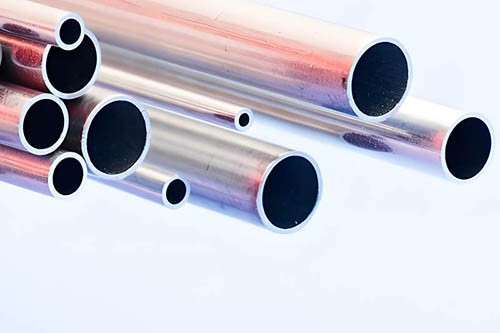

5454 alloy has good corrosion resistance and medium strength, and is suitable for hull structure and pressure vessels. Its corrosion resistance can still be maintained after welding, so that it performs well in applications that require high strength and corrosion resistance. This alloy is especially suitable for use in hull, pressure vessels and pipelines.

- Thickness: 3-500 mm

- Width: 600-2600 mm

- Level: 16000 mm

- Application: hull structure, pressure vessel, pipeline, etc.

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 5454 H32 | 250 | 175 | 18 |

| 5454 H34 | 260 | 200 | 12 |

5A02 O H32 H34 Aluminium Plate for Ship Building

The 5A02 alloy has good corrosion resistance and formability, and is suitable for manufacturing sheet metal parts, fuel tanks and flanges. Its excellent corrosion resistance is particularly important in the marine environment and can ensure the long -term service life of ship components. In addition, the high ductility and low density of the 5A02 alloy make it an ideal material for making light ship structures.

- Thickness: 0.15-600 mm

- Width: 20-2600 mm

- Level: 500-16000 mm

- Application: sheet metal, fuel tank, flange, etc.

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 5A02 O | 170-225 | 70-100 | 23 |

| 5A02 H32 | 275 | 195 | 10-12 |

| 5A02 H34 | 315 | 250 | 9-11 |

5005 H32 H34 H38 Aluminium Plate for Ship Building

The 5005 alloy is widely popular among the shipbuilding industry with its good resistance and welding. Its smooth surface and good formability make it suitable for the decoration and coverage of the ship, such as a curtain wall board. The medium intensity and good antioxidant of the 5005 alloy make it have a variety of applications in ship manufacturing.

- Thickness: 0.15-600 mm

- Width: 20-2600 mm

- Level: 500-16000 mm

- Applications: cooking utensils, instrumental housing, building decoration, ducting curtain wall boards, etc.

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 5052 H32 | 215 | 145 | 12 |

| 5052 H34 | 230 | 170 | 10 |

| 5052 H38 | 270 | 200 | 8 |

6061 T4 T6 T651 Aluminium Plate for Ship Building

The 6061 alloy is widely used in the shipbuilding industry due to its excellent mechanical properties and good processedability. Its high -intensity, good weldability and corrosion resistance make it suitable for machinery parts, structural components and other high -intensity applications for manufacturing ships. The versatility and strength of the 6061 alloy make it an indispensable material in the shipbuilding industry.

- Thickness: 0.2-500 mm

- Width: 600-2600 mm

- Level: 16000 mm

- Application: Mechanical parts, forgeds, commercial vehicles, railway structural parts, ship manufacturing, etc.

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 6061 T4 | 240 | 145 | 20 |

| 6061 T6 | 310 | 275 | 17 |

| 6061 T651 | 310 | 275 | 17 |

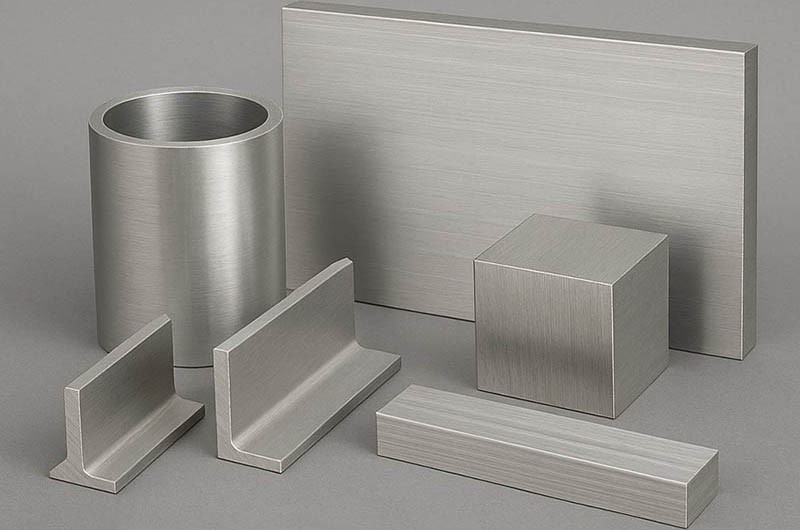

Marine aluminum products you may be interested in

You might be interested in: Marine Grade Aluminum 5083 Marine Grade Aluminum 5052 Marine Aluminum 5059 Marine Aluminum 5454 Marine Aluminum 5456 Marine Aluminum 5383 Marine Aluminum 5086 6 Series Marine Aluminum 5 Series Marine Aluminum Aluminum for Shipbuilding 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5052 aluminum 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5052 aluminum sheet 5052 h32 5052 h34 5052 h32 aluminum 5052 aluminum plate 5052 0 aluminum sheet al5052 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum