How to choose aluminum for ships?

Last Updated :

Consider the location of structural aluminum alloy

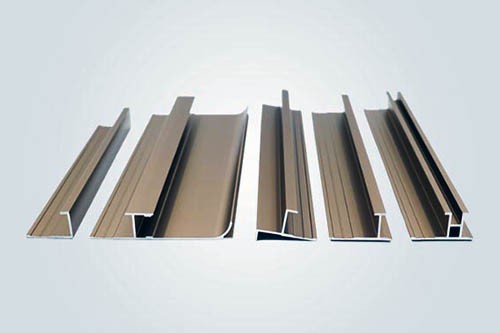

ship superstructure

- Portholes: 6063 aluminum alloy is often used. 6063 aluminum alloy has good corrosion resistance and weldability, and is suitable for use in portholes and other parts.

- Masts and gangways: usually use 6063 and 6061 aluminum alloys. These two aluminum alloys have high strength and good processing properties, and are suitable for use in parts that need to bear certain loads.

deck, hull

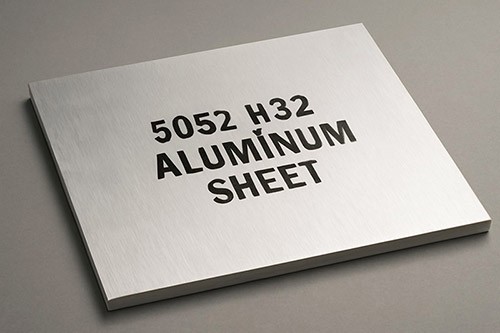

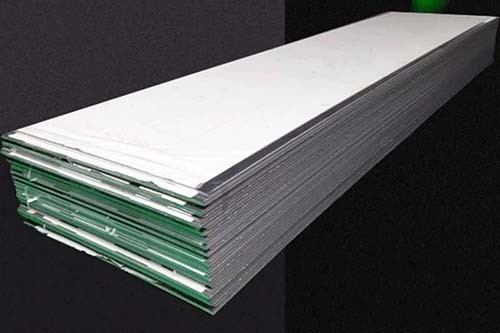

Main materials: 5454, 5052, 5083 aluminum alloy plates. These aluminum alloys have excellent corrosion resistance, tensile strength and weldability, and are very suitable for use in parts such as ship hulls and decks that need to withstand greater strength and harsh marine environments.

- 5454 aluminum alloy: It has high corrosion resistance and strength, and is suitable for use in parts of the hull structure that require corrosion resistance.

- 5052 aluminum alloy: has good processing properties and corrosion resistance, and is often used to manufacture ship decks and other parts.

- 5083 aluminum alloy: has excellent tensile strength and corrosion resistance, and is one of the ideal choices for manufacturing ship hull structures.

When choosing an aluminum alloy, there are other factors to consider, such as cost, availability, weight, etc. Only by comprehensively considering all factors can the most suitable aluminum alloy material for ships be selected.

Marine aluminum products you may be interested in

Consider performance needs

Selecting the appropriate alloy depends on factors such as the vessel's intended use, operating environment and budgetary considerations.

1. Corrosion resistance

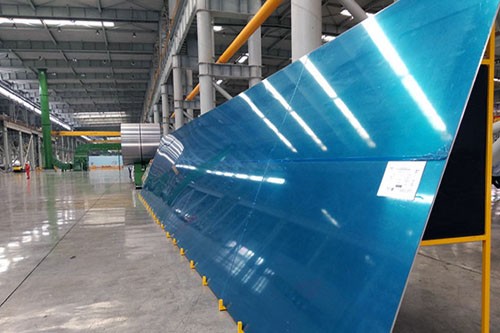

Corrosion poses a significant threat to ships, especially in harsh marine environments characterized by exposure to salt water and atmospheric conditions.

Aluminum's natural oxide layer provides inherent corrosion resistance, but certain alloying elements, such as magnesium and chromium, can enhance this property.

For ships operating in highly corrosive environments, such as coastal waters or offshore platforms, selecting alloys with high corrosion resistance, such as 5000 series alloys, is critical to ensure long-term durability and save maintenance costs.

2. Strength and durability

Although aluminum is lighter than steel, it has an impressive strength-to-weight ratio, making it an attractive option for the shipbuilding industry.

High-strength aluminum alloys, such as 6000 series aluminum alloys, have excellent mechanical properties and can be used to build lightweight yet strong structures.

3. Solderability and Fabrication

Weldability is a critical factor in the shipbuilding industry as it affects the ease of assembly and structural integrity of a vessel.

Aluminum alloys exhibit excellent weldability, and most alloys can be easily welded using a variety of techniques, including gas metal arc welding (GMAW) and tungsten inert gas welding (TIG).

Correct welding procedures, including preheating and post-weld heat treatment, are essential to reduce the risk of welding defects and ensure optimal joint strength.

Manufacturing processes such as extrusion, casting and CNC machining can produce complex aluminum components with tight tolerances, making shipbuilding more efficient.

4. Cost considerations

While aluminum offers many advantages to the shipbuilding industry, it is critical to evaluate the cost implications associated with its use.

Aluminum generally requires higher material costs compared to steel, but potential savings in fuel consumption, maintenance and life cycle costs can offset the initial investment.

Shipbuilders must conduct a thorough cost-benefit analysis to determine the most economical material selection for their specific project requirements.

Factors such as material supply, market fluctuations and economies of scale also affect the overall cost of aluminum shipbuilding.

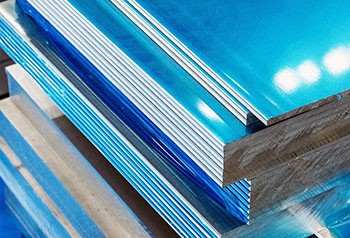

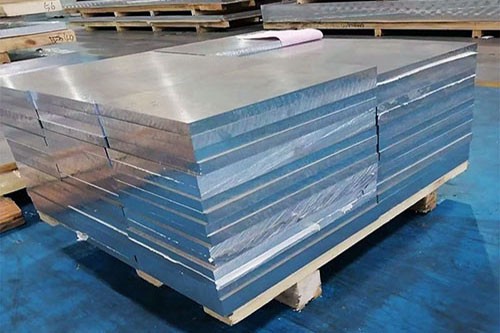

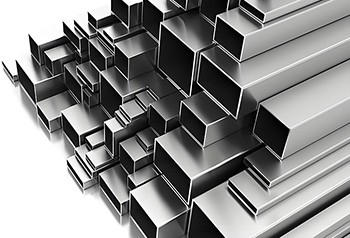

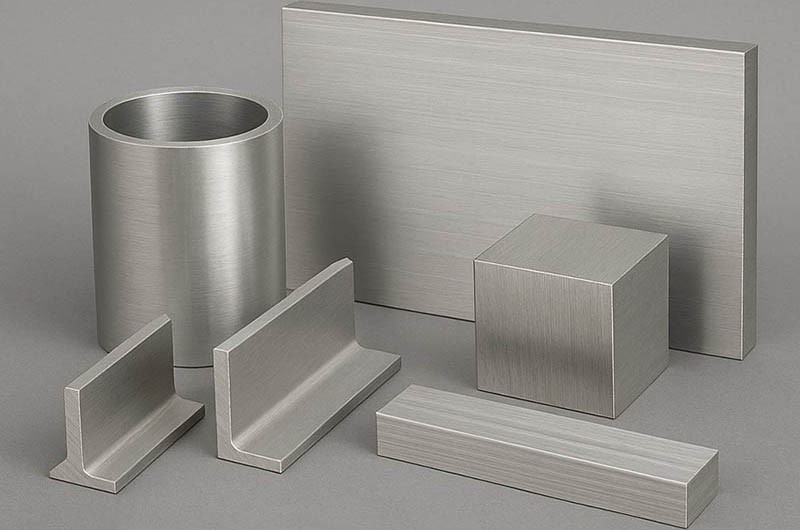

Marine Grade Aluminum Materials for Ship Structure

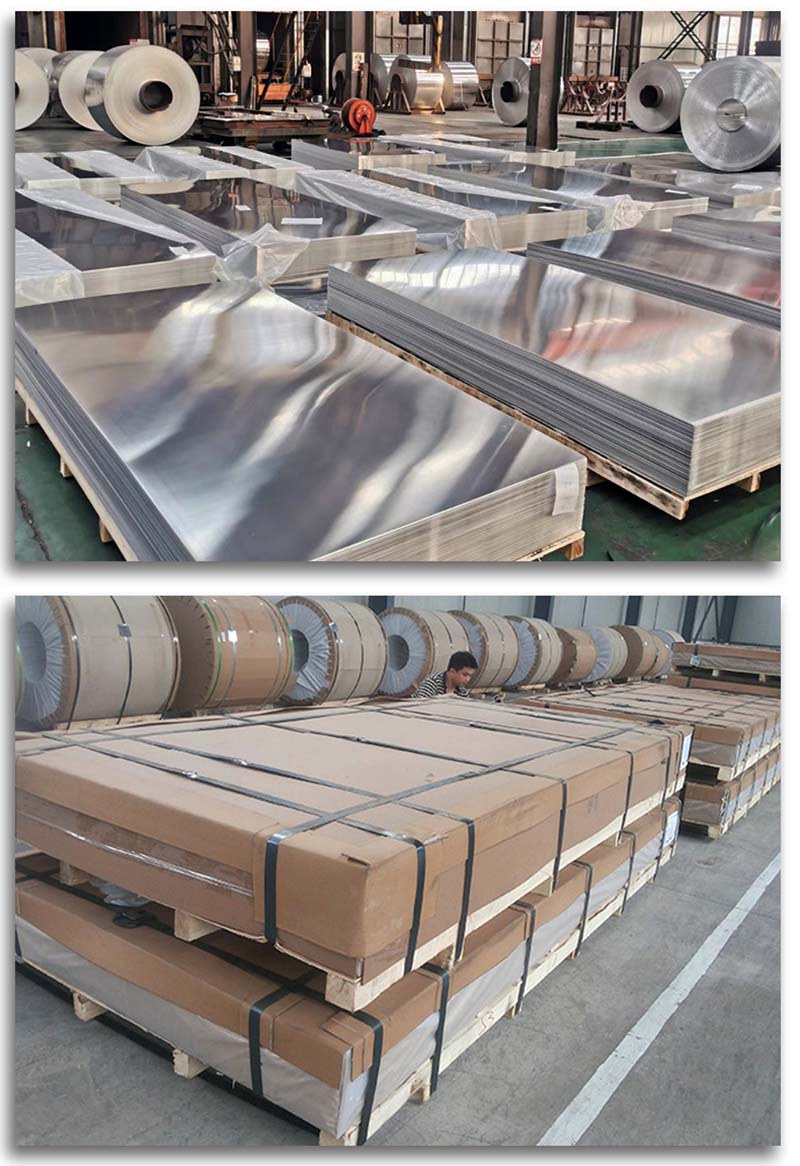

Haomei Aluminum is a manufacturer dedicated to the production and sales of ship plates, marine aluminum welding wires, marine aluminum profiles and other marine-related products, with guaranteed quality and competitive prices.

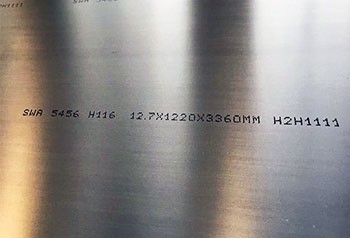

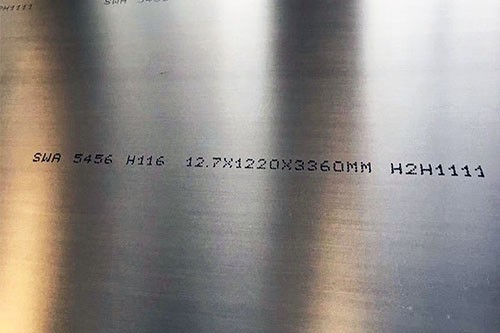

You might be interested in: Marine Grade Aluminum 5083 Marine Grade Aluminum 5052 Marine Aluminum 6061 Marine Aluminum 5754 Marine Aluminum 5059 Marine Aluminum 6082 Marine Aluminum 5454 Marine Aluminum 5456 Marine Aluminum 5383 Marine Aluminum 5086 Aluminum for Boat 5 Series Marine Aluminum 6 Series Marine Aluminum Aluminum for Shipbuilding 5083 aluminum 5083 aluminum plate 5083 aluminum sheet 5052 aluminum 5083 aluminum supplier 5083 h321 5083 h116 5083 aluminum sheet price aluminium 5083 sheet aluminium 5083 price per kg 5083 h112 5083 aluminium sheet price aluminium aw 5083 5083 plate 5083 h32 aw 5083 aluminium aluminium en aw 5083 aluminium 5083 h116 aluminum alloy 5083 aluminium 5083 h321 aluminum 5083 price alloy 5083 5083 aluminium plate price 5083 aluminium welding 5083 sheet a5083 aluminum a5083 h321 a5083 material aa 5083 aluminum aa5083 alloy aa5083 aluminium alloy al 5083 h112 al alloy 5083 aluminium 5083h111 astm 5083 en 5083 aluminium en aw 5083 aluminum welding 5083 aluminum 5052 aluminum sheet 5052 h32 5052 h34 5052 h32 aluminum 5052 aluminum plate 5052 0 aluminum sheet al5052 5083 h32 aluminum aluminum 5083 h32 5083 0 aluminum